**Diagnosing and Troubleshooting Car ABS Problems with Xentry: A Comprehensive Guide**

The car’s ABS system has a problem, and you need to diagnose and troubleshoot it effectively. CARDIAGTECH.NET offers a solution by guiding you on how to use Xentry, a powerful diagnostic tool, to identify the root cause of the ABS issue, perform necessary repairs, and ensure the vehicle’s safety systems are functioning optimally. Learn about ABS diagnostics, troubleshooting tips, and Xentry usage to resolve automotive ABS problems efficiently.

1. What is the ABS System and Why is Accurate Diagnosis Crucial?

The Anti-lock Braking System (ABS) is a critical safety feature in modern vehicles. It prevents the wheels from locking up during braking, allowing the driver to maintain steering control and reduce stopping distances. Accurate diagnosis is vital for ensuring the ABS functions correctly, maintaining vehicle safety, and preventing accidents.

The ABS system relies on a network of sensors, hydraulic components, and electronic control units to function properly. According to the National Highway Traffic Safety Administration (NHTSA), ABS can reduce the risk of certain types of crashes by as much as 10-15%. When the ABS malfunctions, it can compromise braking performance and increase the risk of accidents. For example, a study by the University of Michigan Transportation Research Institute found that vehicles with malfunctioning ABS had a 27% higher risk of being involved in a crash during emergency braking situations.

- Sensors: Wheel speed sensors monitor the rotational speed of each wheel.

- Hydraulic Unit: Modulates brake pressure to prevent wheel lockup.

- ECU: Processes sensor data and controls the hydraulic unit.

2. What are Common Symptoms Indicating ABS Problems?

Identifying common symptoms of ABS issues is the first step in diagnosing and troubleshooting the system effectively.

- ABS Warning Light: The ABS warning light on the dashboard illuminates.

- Unusual Braking Feel: A pulsating or vibrating sensation when braking.

- Extended Stopping Distances: Noticeably longer distances required to stop the vehicle.

- Wheel Lockup: Wheels locking up during braking, especially on slippery surfaces.

- Brake Pedal Issues: A hard or unresponsive brake pedal.

3. How Does Xentry Aid in Diagnosing ABS Problems?

Xentry is a comprehensive diagnostic tool used for Mercedes-Benz vehicles. It provides in-depth access to the vehicle’s electronic systems, allowing technicians to read fault codes, monitor live data, and perform diagnostic tests.

Xentry is particularly useful for diagnosing ABS problems because it can:

- Read ABS Fault Codes: Identify specific issues within the ABS system.

- Monitor Live Data: Observe real-time sensor data, such as wheel speeds and brake pressures.

- Perform Actuator Tests: Test the functionality of ABS components, such as solenoids and pumps.

- Access System Diagrams: View detailed schematics of the ABS system.

4. What are the Key Features of Xentry for ABS Diagnostics?

Xentry offers several features that make it an invaluable tool for diagnosing ABS problems.

| Feature | Description |

|---|---|

| Fault Code Reading | Retrieves diagnostic trouble codes (DTCs) related to the ABS system. |

| Live Data Monitoring | Displays real-time data from ABS sensors, allowing for the observation of system behavior under various conditions. |

| Actuator Tests | Enables technicians to activate individual components within the ABS system to verify their functionality. |

| System Diagrams | Provides detailed schematics of the ABS system, aiding in the identification of components and wiring. |

5. Step-by-Step Guide: Using Xentry to Diagnose ABS Issues

Follow these steps to effectively diagnose ABS issues using Xentry:

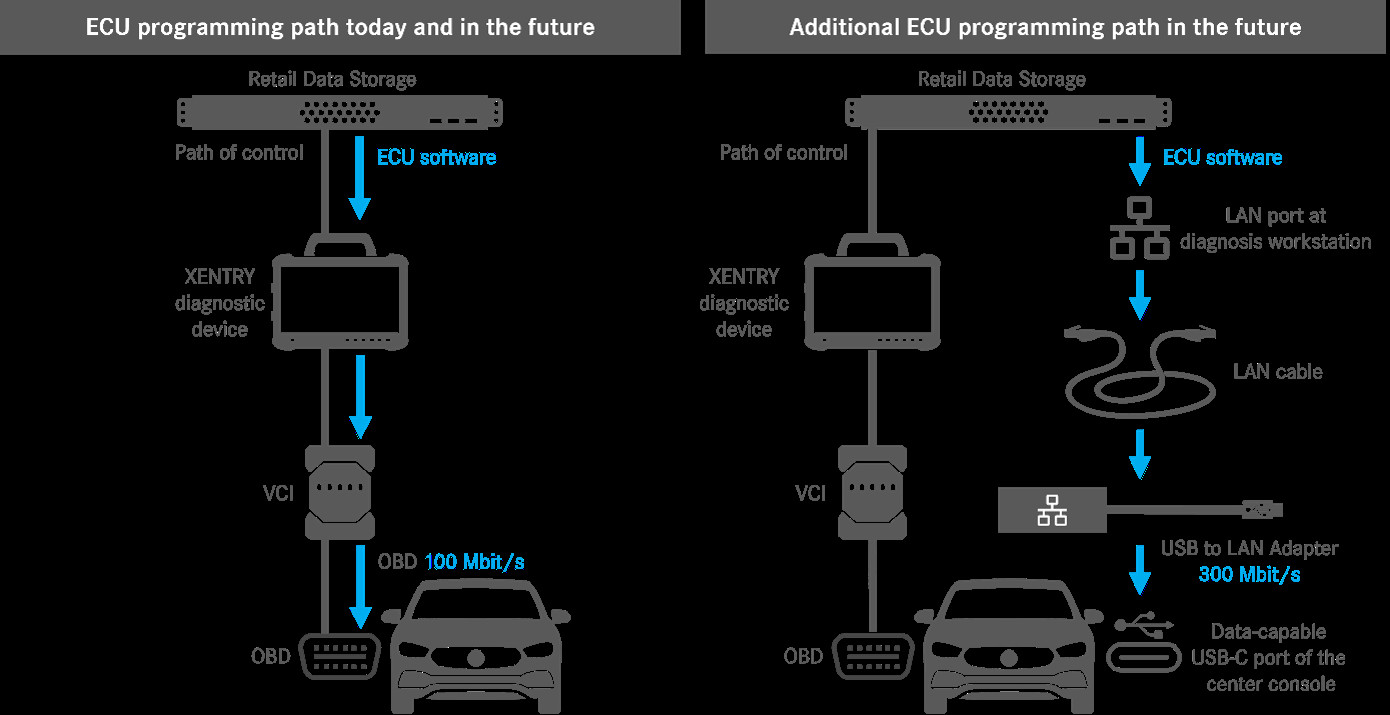

Step 1: Connect Xentry to the Vehicle

- Plug the Xentry diagnostic interface into the vehicle’s OBD-II port.

- Ensure the vehicle’s ignition is turned on.

- Launch the Xentry software on your computer.

Step 2: Select Vehicle Model and System

- In Xentry, select the correct vehicle model and year.

- Navigate to the ABS system in the control unit selection menu.

Step 3: Read Fault Codes

- Select the “Read Fault Codes” option to retrieve any stored DTCs.

- Record all fault codes and their descriptions.

Step 4: Interpret Fault Codes

- Use the Xentry software or a diagnostic database to interpret the fault codes.

- Identify the potential causes of each fault code.

Step 5: Monitor Live Data

- Select the “Live Data” or “Actual Values” option.

- Monitor wheel speed sensor readings, brake pressure values, and other relevant data while driving or simulating driving conditions.

Step 6: Perform Actuator Tests

- Use the “Actuator Tests” function to test individual ABS components.

- Activate solenoids, pumps, and other components to verify their functionality.

Step 7: Analyze Results and Plan Repairs

- Analyze the fault codes, live data, and actuator test results to identify the root cause of the ABS problem.

- Develop a repair plan based on your findings.

6. What are Common ABS Fault Codes and Their Meanings?

Understanding common ABS fault codes and their meanings is essential for accurate diagnosis.

| Fault Code | Description | Possible Cause |

|---|---|---|

| C0031 | Left Front Wheel Speed Sensor Circuit Malfunction | Faulty wheel speed sensor, wiring issue, or ABS module problem. |

| C0034 | Right Front Wheel Speed Sensor Circuit Malfunction | Faulty wheel speed sensor, wiring issue, or ABS module problem. |

| C0037 | Left Rear Wheel Speed Sensor Circuit Malfunction | Faulty wheel speed sensor, wiring issue, or ABS module problem. |

| C0040 | Right Rear Wheel Speed Sensor Circuit Malfunction | Faulty wheel speed sensor, wiring issue, or ABS module problem. |

| C0061 | ABS Solenoid Valve Circuit Malfunction | Faulty solenoid valve, wiring issue, or ABS module problem. |

| C0080 | ABS Pump Motor Circuit Malfunction | Faulty pump motor, wiring issue, or ABS module problem. |

| C0100 | Brake Pressure Sensor Circuit Malfunction | Faulty pressure sensor, wiring issue, or ABS module problem. |

| C1000 | Control Unit Fault | Internal ABS module failure. |

| U0121 | Lost Communication With Anti-Lock Brake System (ABS) Control Module | Wiring issue, faulty ABS module, or CAN bus problem. |

| U1000 | CAN Communication Bus Fault | Problem with the CAN bus network, affecting communication between modules. |

7. How to Interpret Live Data from ABS Sensors Using Xentry

Monitoring live data from ABS sensors provides valuable insights into the system’s operation.

Wheel Speed Sensors

- Purpose: Measure the rotational speed of each wheel.

- Interpretation: All wheel speed sensors should show similar readings during straight-line driving. Discrepancies indicate a potential sensor issue.

- Example: If one wheel speed sensor shows a reading of 0 km/h while the others show 50 km/h, the sensor is likely faulty.

Brake Pressure Sensors

- Purpose: Measure the pressure in the brake lines.

- Interpretation: Brake pressure should increase when the brake pedal is applied. Irregular pressure readings may indicate a faulty sensor or hydraulic issue.

- Example: If the brake pressure sensor shows no change in pressure when the brake pedal is depressed, the sensor may be faulty or there may be a hydraulic problem.

Steering Angle Sensor

- Purpose: Measures the angle of the steering wheel.

- Interpretation: The steering angle sensor reading should correspond to the actual steering wheel position. Incorrect readings can affect ABS and ESP functionality.

- Example: If the steering angle sensor reads 90 degrees when the steering wheel is straight, the sensor needs calibration or replacement.

8. How to Perform Actuator Tests on ABS Components with Xentry

Actuator tests allow technicians to activate individual ABS components to verify their functionality.

Solenoid Valve Test

- Purpose: Test the operation of the ABS solenoid valves, which control brake pressure.

- Procedure: Use Xentry to activate each solenoid valve individually and listen for a clicking sound.

- Interpretation: If a solenoid valve does not activate or makes unusual noises, it may be faulty.

Pump Motor Test

- Purpose: Test the operation of the ABS pump motor, which provides hydraulic pressure.

- Procedure: Use Xentry to activate the pump motor and monitor its performance.

- Interpretation: If the pump motor does not run or produces insufficient pressure, it may be faulty.

Wheel Speed Sensor Simulation

- Purpose: Simulate wheel speed sensor signals to test the ABS module’s response.

- Procedure: Use Xentry to simulate different wheel speed signals and observe the ABS module’s reaction.

- Interpretation: If the ABS module does not respond correctly to the simulated signals, it may be faulty.

9. What are Common Troubleshooting Tips for ABS Problems?

Here are some practical troubleshooting tips for addressing ABS problems:

- Check Wheel Speed Sensors: Inspect sensors for damage, contamination, or loose connections.

- Inspect Wiring: Check wiring harnesses for damage, corrosion, or loose connections.

- Test Hydraulic Components: Verify the functionality of the ABS pump, modulator, and brake lines.

- Check Brake Fluid Level: Ensure the brake fluid reservoir is filled to the correct level.

- Inspect ABS Relays and Fuses: Check for blown fuses or faulty relays in the ABS circuit.

10. How to Diagnose and Repair Wheel Speed Sensor Issues

Wheel speed sensors are a common source of ABS problems. Here’s how to diagnose and repair them:

Symptoms of Faulty Wheel Speed Sensors

- ABS warning light illumination.

- Erratic ABS activation.

- Loss of traction control or stability control.

Diagnosis Steps

- Visual Inspection: Check the sensor for physical damage, such as cracks or breaks.

- Wiring Inspection: Inspect the wiring harness for damage, corrosion, or loose connections.

- Resistance Test: Use a multimeter to measure the sensor’s resistance. Compare the reading to the manufacturer’s specifications.

- Signal Test: Use an oscilloscope to monitor the sensor’s output signal while the wheel is rotating.

Repair Steps

- Cleaning: Clean the sensor and tone ring of any debris or contamination.

- Wiring Repair: Repair any damaged wiring or replace faulty connectors.

- Sensor Replacement: If the sensor is faulty, replace it with a new one.

- Calibration: Calibrate the new sensor using Xentry or a similar diagnostic tool.

11. How to Address ABS Hydraulic Issues

Hydraulic problems can also cause ABS malfunctions.

Symptoms of Hydraulic Issues

- Hard brake pedal.

- Extended stopping distances.

- ABS warning light illumination.

Diagnosis Steps

- Visual Inspection: Check the brake lines, hoses, and hydraulic unit for leaks or damage.

- Pressure Test: Use a brake pressure gauge to measure the pressure in the brake lines.

- Actuator Test: Use Xentry to activate the ABS pump and modulator to verify their functionality.

Repair Steps

- Leak Repair: Repair any leaks in the brake lines or hoses.

- Hydraulic Unit Replacement: If the hydraulic unit is faulty, replace it with a new or remanufactured unit.

- Brake Bleeding: Bleed the brake system to remove any air bubbles.

- Fluid Flush: Flush the brake fluid to remove contaminants and ensure proper system operation.

12. What Role Does the Electronic Control Unit (ECU) Play in ABS?

The ECU is the brain of the ABS system, responsible for processing sensor data and controlling the hydraulic unit.

Symptoms of ECU Issues

- ABS warning light illumination.

- Erratic ABS activation.

- Complete ABS failure.

Diagnosis Steps

- Fault Code Scan: Use Xentry to scan for fault codes related to the ECU.

- Wiring Inspection: Inspect the wiring harness and connectors for damage or corrosion.

- Voltage Test: Check the voltage supply to the ECU to ensure it is within the specified range.

- Communication Test: Verify that the ECU is communicating with other vehicle systems using Xentry.

Repair Steps

- Wiring Repair: Repair any damaged wiring or replace faulty connectors.

- ECU Replacement: If the ECU is faulty, replace it with a new or remanufactured unit.

- Programming: Program the new ECU using Xentry to ensure it is compatible with the vehicle.

13. How to Diagnose CAN Bus Communication Problems Affecting ABS

CAN bus communication problems can disrupt the ABS system’s ability to function correctly.

Symptoms of CAN Bus Issues

- Multiple warning lights on the dashboard.

- Loss of communication with multiple control modules.

- Erratic system behavior.

Diagnosis Steps

- Fault Code Scan: Use Xentry to scan for fault codes related to CAN bus communication.

- Wiring Inspection: Inspect the CAN bus wiring for damage, corrosion, or shorts.

- Resistance Test: Measure the resistance of the CAN bus wiring to ensure it is within the specified range.

- Oscilloscope Test: Use an oscilloscope to monitor the CAN bus signals and identify any anomalies.

Repair Steps

- Wiring Repair: Repair any damaged wiring or replace faulty connectors.

- Module Replacement: If a control module is causing the CAN bus problem, replace it with a new or remanufactured unit.

- CAN Bus Diagnosis Tools: Use specialized CAN bus diagnostic tools to identify and resolve communication issues.

14. How to Check and Maintain ABS Relays and Fuses

Relays and fuses are essential components in the ABS electrical circuit.

Symptoms of Relay or Fuse Issues

- ABS warning light illumination.

- Complete ABS failure.

Diagnosis Steps

- Visual Inspection: Check the relays and fuses for signs of damage or corrosion.

- Continuity Test: Use a multimeter to test the continuity of the fuses.

- Relay Test: Use a relay tester to verify that the relays are functioning correctly.

Maintenance Steps

- Replacement: Replace any blown fuses or faulty relays with new ones of the correct rating.

- Cleaning: Clean any corroded contacts on the relays and fuses.

- Secure Connections: Ensure that all relays and fuses are securely seated in their sockets.

15. What is the Importance of Regular ABS Maintenance?

Regular ABS maintenance is crucial for ensuring the system’s reliability and effectiveness.

Maintenance Tasks

- Brake Fluid Flush: Replace the brake fluid every two years to remove contaminants and moisture.

- Wheel Speed Sensor Inspection: Inspect the wheel speed sensors for damage or contamination during brake service.

- Brake Pad Inspection: Check the brake pads for wear and replace them as needed.

- Brake Line Inspection: Inspect the brake lines and hoses for leaks or damage.

Benefits of Maintenance

- Improved Safety: Ensures the ABS system functions correctly, reducing the risk of accidents.

- Extended Component Life: Prevents premature wear and failure of ABS components.

- Optimal Performance: Maintains the ABS system’s effectiveness, providing reliable braking performance.

16. How Does Brake Fluid Condition Impact ABS Performance?

The condition of the brake fluid significantly impacts ABS performance.

Effects of Contaminated Brake Fluid

- Reduced Boiling Point: Contaminated brake fluid has a lower boiling point, increasing the risk of brake fade.

- Corrosion: Moisture in the brake fluid can cause corrosion of ABS components.

- Reduced Performance: Contaminated brake fluid can reduce the effectiveness of the ABS system.

Maintenance Recommendations

- Regular Flushes: Flush the brake fluid every two years or as recommended by the vehicle manufacturer.

- Fluid Type: Use the correct type of brake fluid specified for your vehicle.

- Inspection: Inspect the brake fluid for contamination or discoloration during routine maintenance.

17. How Can You Prevent Future ABS Problems?

Preventing future ABS problems involves proactive maintenance and careful driving habits.

Preventive Measures

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule for the ABS system.

- Driving Habits: Avoid harsh braking and aggressive driving, which can put excessive stress on the ABS system.

- Prompt Repairs: Address any ABS warning lights or symptoms immediately to prevent further damage.

- Quality Components: Use high-quality replacement parts when repairing the ABS system.

18. The Role of Software Updates in Maintaining ABS Functionality

Software updates are essential for maintaining the functionality and performance of the ABS system.

Importance of Updates

- Bug Fixes: Software updates can address bugs and glitches in the ABS control module.

- Performance Improvements: Updates can improve the ABS system’s performance and responsiveness.

- Compatibility: Updates ensure the ABS system is compatible with other vehicle systems.

Updating Procedure

- Check for Updates: Use Xentry to check for available software updates for the ABS control module.

- Installation: Follow the on-screen instructions in Xentry to install the software updates.

- Verification: Verify that the updates have been installed correctly and that the ABS system is functioning properly.

19. How to Handle Intermittent ABS Faults

Intermittent ABS faults can be challenging to diagnose.

Troubleshooting Tips

- Record Data: Use Xentry to record live data and fault codes when the problem occurs.

- Inspect Wiring: Check the wiring and connectors for intermittent connections or damage.

- Component Testing: Test individual ABS components when the problem is present to identify the source of the fault.

- Road Testing: Perform road tests under various conditions to try to replicate the problem.

Common Causes

- Loose wiring connections.

- Faulty sensors.

- Intermittent ECU problems.

20. The Impact of Wheel Alignment on ABS Performance

Wheel alignment can affect ABS performance.

Effects of Misalignment

- Uneven Tire Wear: Misalignment can cause uneven tire wear, affecting the accuracy of wheel speed sensors.

- Erratic ABS Activation: Misalignment can cause the ABS system to activate erratically.

- Reduced Braking Performance: Misalignment can reduce braking performance, especially during emergency stops.

Recommendations

- Regular Alignment Checks: Have the wheel alignment checked regularly, especially after hitting potholes or curbs.

- Correct Alignment: Ensure the wheel alignment is within the manufacturer’s specifications.

- Tire Condition: Maintain proper tire pressure and replace worn tires to ensure optimal ABS performance.

21. How to Diagnose ABS Issues Related to Tire Size and Condition

Tire size and condition can impact ABS performance.

Effects of Incorrect Tire Size or Condition

- Inaccurate Wheel Speed Readings: Different tire sizes can cause inaccurate wheel speed readings, affecting ABS functionality.

- Reduced Traction: Worn tires can reduce traction, increasing the likelihood of ABS activation.

- Erratic ABS Behavior: Mismatched tire sizes or conditions can cause erratic ABS behavior.

Recommendations

- Matching Tires: Use the same size and type of tires on all four wheels.

- Proper Inflation: Maintain proper tire pressure to ensure accurate wheel speed readings and optimal traction.

- Regular Inspections: Inspect the tires regularly for wear and damage.

22. What is the Procedure for Clearing ABS Fault Codes After Repairs?

After completing ABS repairs, it is essential to clear the fault codes.

Clearing Procedure

- Verify Repairs: Ensure that all repairs have been completed and the ABS system is functioning properly.

- Connect Xentry: Connect Xentry to the vehicle and navigate to the ABS system.

- Clear Fault Codes: Select the “Clear Fault Codes” option to erase the stored DTCs.

- Verify Clearing: Verify that all fault codes have been cleared and that the ABS warning light is no longer illuminated.

23. The Importance of Professional Tools Like Xentry for ABS Diagnostics

Professional tools like Xentry are essential for accurate and efficient ABS diagnostics.

Benefits of Xentry

- Comprehensive Data: Provides access to detailed diagnostic data and system information.

- Accurate Diagnosis: Helps technicians accurately diagnose ABS problems.

- Efficient Repairs: Streamlines the repair process, reducing downtime and costs.

- Software Updates: Allows for software updates to ensure optimal system performance.

Alternative Tools

- OBD-II Scanners: Basic OBD-II scanners can read ABS fault codes but may not provide detailed data.

- Generic Scan Tools: Generic scan tools offer more advanced features but may not be as comprehensive as Xentry for Mercedes-Benz vehicles.

24. How to Ensure Accurate Readings and Avoid Misdiagnosis with Xentry

Ensuring accurate readings and avoiding misdiagnosis with Xentry is crucial for effective ABS troubleshooting.

Tips for Accurate Readings

- Proper Connection: Ensure that Xentry is properly connected to the vehicle and that all connections are secure.

- Correct Vehicle Selection: Select the correct vehicle model and year in the Xentry software.

- Up-to-Date Software: Use the latest version of the Xentry software to ensure accurate readings and access to the latest diagnostic information.

- Follow Procedures: Follow the recommended diagnostic procedures in Xentry to avoid errors.

Avoiding Misdiagnosis

- Verify Fault Codes: Verify that the fault codes are accurate and relevant to the symptoms.

- Interpret Data: Carefully interpret the live data and actuator test results to identify the root cause of the problem.

- Consult Resources: Consult technical resources and repair manuals for additional information and guidance.

- Professional Advice: Seek advice from experienced technicians or diagnostic specialists if needed.

25. What Training and Resources are Available for Using Xentry Effectively?

Proper training and resources are essential for using Xentry effectively.

Training Options

- Online Courses: Many online courses offer training on using Xentry for diagnostics and repair.

- Technical Schools: Technical schools and colleges offer courses on automotive diagnostics, including Xentry training.

- Manufacturer Training: Mercedes-Benz offers training programs for technicians on using Xentry and other diagnostic tools.

Resources

- User Manuals: The Xentry user manual provides detailed information on using the software.

- Technical Forums: Online technical forums offer a wealth of information and support from experienced technicians.

- Diagnostic Databases: Diagnostic databases provide fault code definitions, troubleshooting tips, and repair procedures.

26. Advanced Diagnostics: Using Xentry for Complex ABS Problems

For complex ABS problems, advanced diagnostic techniques may be required.

Techniques

- Waveform Analysis: Use an oscilloscope to analyze the waveforms of ABS sensor signals.

- Circuit Testing: Use a multimeter to test the ABS electrical circuits for shorts, opens, or high resistance.

- Component Isolation: Isolate individual ABS components to determine if they are causing the problem.

Example Scenario

Consider a scenario where the ABS warning light is illuminated, and Xentry shows multiple fault codes related to wheel speed sensors. Advanced diagnostics might involve using an oscilloscope to analyze the wheel speed sensor signals to identify a specific sensor with a distorted waveform.

27. Understanding the Relationship Between ABS, ESP, and Other Vehicle Systems

The ABS system often works in conjunction with other vehicle systems, such as Electronic Stability Program (ESP).

Integration with ESP

- Shared Components: ABS and ESP share many components, such as wheel speed sensors and hydraulic modulators.

- Coordinated Control: ESP uses ABS to prevent wheel lockup and maintain stability during cornering and emergency maneuvers.

- Fault Code Interactions: Faults in one system can affect the operation of the other.

Other Systems

- Traction Control: ABS is often integrated with traction control systems to prevent wheel spin during acceleration.

- Brake Assist: Brake assist systems use ABS sensors to detect emergency braking situations and apply maximum braking force.

28. Real-World Case Studies: Diagnosing ABS Issues with Xentry

Examining real-world case studies can provide valuable insights into diagnosing ABS issues with Xentry.

Case Study 1: Faulty Wheel Speed Sensor

- Symptoms: ABS warning light, erratic ABS activation.

- Fault Codes: C0031 (Left Front Wheel Speed Sensor Circuit Malfunction).

- Diagnosis: Using Xentry, the technician monitored the live data from the wheel speed sensors and found that the left front sensor was producing erratic readings.

- Repair: The technician replaced the faulty wheel speed sensor, cleared the fault codes, and verified that the ABS system was functioning properly.

Case Study 2: ABS Pump Motor Failure

- Symptoms: ABS warning light, hard brake pedal.

- Fault Codes: C0080 (ABS Pump Motor Circuit Malfunction).

- Diagnosis: Using Xentry, the technician performed an actuator test on the ABS pump motor and found that it was not functioning.

- Repair: The technician replaced the faulty ABS pump motor, bled the brake system, and cleared the fault codes.

29. Staying Updated: Keeping Up with the Latest ABS Technology and Diagnostic Techniques

Staying updated with the latest ABS technology and diagnostic techniques is essential for automotive technicians.

Methods for Staying Updated

- Industry Publications: Read automotive industry publications and journals to stay informed about new technologies and diagnostic techniques.

- Training Courses: Attend training courses and seminars on ABS diagnostics and repair.

- Online Forums: Participate in online forums and communities to exchange information and learn from other technicians.

- Technical Bulletins: Review technical service bulletins (TSBs) from vehicle manufacturers to stay informed about common problems and repair procedures.

30. How to Choose the Right Diagnostic Tools and Equipment for ABS Repairs

Choosing the right diagnostic tools and equipment is crucial for effective ABS repairs.

Essential Tools

- Xentry Diagnostic System: A comprehensive diagnostic tool for Mercedes-Benz vehicles.

- Multimeter: A versatile tool for testing electrical circuits and components.

- Oscilloscope: A tool for analyzing electrical signals and waveforms.

- Brake Pressure Gauge: A tool for measuring brake pressure.

- Brake Bleeder: A tool for bleeding the brake system.

Factors to Consider

- Compatibility: Ensure that the tools are compatible with the vehicles you will be working on.

- Accuracy: Choose tools that provide accurate and reliable readings.

- Durability: Select tools that are durable and can withstand the demands of a professional shop environment.

- Cost: Balance the cost of the tools with their features and benefits.

Is your garage facing challenges with ABS diagnostics? Do you struggle with pinpointing the exact issue and performing efficient repairs? At CARDIAGTECH.NET, we understand the frustration of dealing with complex automotive systems. Our range of diagnostic tools, including Xentry, is designed to enhance your repair process, reduce downtime, and increase customer satisfaction.

Contact us today at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET for a consultation. Our expert team is ready to assist you in selecting the perfect tools tailored to your specific needs. Located at 276 Reock St, City of Orange, NJ 07050, United States, we are here to help you elevate your diagnostic capabilities and achieve unparalleled efficiency. Don’t let ABS problems slow you down—reach out now and discover how CARDIAGTECH.NET can transform your garage’s performance.

FAQ Section: ABS Diagnostics and Troubleshooting with Xentry

1. What is the ABS system, and why is it important?

The Anti-lock Braking System (ABS) is a crucial safety feature that prevents wheel lockup during braking, maintaining steering control and reducing stopping distances. Its proper function is vital for vehicle safety.

2. What are the common symptoms of ABS problems?

Common symptoms include the ABS warning light, unusual braking feel, extended stopping distances, wheel lockup, and brake pedal issues.

3. How does Xentry help in diagnosing ABS problems?

Xentry reads fault codes, monitors live data, performs actuator tests, and provides system diagrams, enabling technicians to pinpoint ABS issues accurately.

4. What are some common ABS fault codes and their meanings?

Common fault codes include C0031 (Left Front Wheel Speed Sensor Malfunction) and C0080 (ABS Pump Motor Circuit Malfunction), each indicating specific system issues.

5. How do I interpret live data from ABS sensors using Xentry?

Monitor wheel speed sensor readings, brake pressure values, and steering angle sensor data in real-time to identify discrepancies indicating sensor or hydraulic issues.

6. How can I perform actuator tests on ABS components with Xentry?

Use Xentry to activate solenoid valves and the pump motor to verify their functionality and identify faulty components.

7. What are some common troubleshooting tips for ABS problems?

Check wheel speed sensors, inspect wiring, test hydraulic components, check brake fluid level, and inspect ABS relays and fuses.

8. How can I prevent future ABS problems?

Regular maintenance, careful driving habits, prompt repairs, and the use of quality components are key to preventing future ABS issues.

9. Why is brake fluid condition important for ABS performance?

Contaminated brake fluid can reduce the boiling point, cause corrosion, and reduce the effectiveness of the ABS system. Regular flushes are essential.

10. What training and resources are available for using Xentry effectively?

Online courses, technical schools, manufacturer training, user manuals, and technical forums offer valuable resources for mastering Xentry.