How To Ensure Safety When Performing Diagnostic Operations With Xentry?

Performing diagnostic operations with Xentry demands a steadfast commitment to safety. This guide, brought to you by CARDIAGTECH.NET, offers vital insights into maintaining a secure working environment while utilizing Xentry. By adhering to these guidelines, you can protect yourself and your equipment while ensuring optimal performance in automotive diagnostics. This includes vehicle diagnostic tools, automotive software, and OBD2 scanners.

1. Understanding the Intent Behind Diagnostic Safety

Diagnostic operations are essential for maintaining and repairing modern vehicles. However, these operations can also present significant safety risks if not handled correctly. Understanding the intent behind diagnostic safety is the first step in creating a safer work environment.

1.1 Why is Safety Critical in Diagnostic Work?

Working with Xentry involves interacting with a vehicle’s electrical and mechanical systems. According to a study by the National Institute for Occupational Safety and Health (NIOSH) in 2022, electrical hazards and moving machinery are primary causes of injury in automotive repair shops. Safety protocols are designed to mitigate these risks, protecting technicians from potential harm.

1.2 The Role of Xentry in Vehicle Diagnostics

Xentry is a comprehensive diagnostic tool used for Mercedes-Benz vehicles. It allows technicians to perform advanced diagnostics, programming, and calibrations. According to Mercedes-Benz’s official training manuals, using Xentry requires a thorough understanding of vehicle systems and adherence to safety guidelines to prevent damage to the vehicle and ensure technician safety.

1.3 Importance of Staying Updated on Safety Protocols

The automotive industry is constantly evolving, with new technologies and diagnostic procedures being introduced regularly. Staying updated on the latest safety protocols is essential for technicians to adapt to these changes and maintain a safe working environment. According to the Automotive Service Excellence (ASE), continuous education and training are critical for staying current with industry best practices and safety standards.

2. Essential Safety Equipment for Xentry Diagnostic Operations

Having the right safety equipment is paramount when performing diagnostic operations with Xentry. This equipment protects technicians from potential hazards such as electrical shocks, chemical exposure, and physical injuries.

2.1 Personal Protective Equipment (PPE)

PPE is the first line of defense against workplace hazards. According to OSHA (Occupational Safety and Health Administration), the following PPE is essential for diagnostic operations:

- Safety Glasses: Protects eyes from debris and chemical splashes.

- Gloves: Insulated gloves protect against electrical shocks, while chemical-resistant gloves protect against hazardous substances.

- Protective Clothing: Coveralls or aprons protect skin from oil, grease, and chemicals.

- Steel-Toed Boots: Protect feet from falling objects and heavy equipment.

- Hearing Protection: Earplugs or earmuffs protect against prolonged exposure to loud noises.

2.2 Diagnostic Tools and Equipment

Using properly maintained and calibrated diagnostic tools is crucial for safety. According to a study by the University of Michigan’s Center for Automotive Research in 2023, faulty equipment is a significant contributor to workplace accidents.

- Xentry Diagnostic Interface: Ensure the interface is in good working condition and properly connected to the vehicle and computer.

- Multimeter: Use a high-quality multimeter to measure voltage, current, and resistance safely.

- Battery Tester: Check battery health to avoid unexpected power surges or failures.

- OBD2 Scanner: Use a reliable OBD2 scanner to read and clear diagnostic trouble codes. You can find high-quality OBD2 scanners at CARDIAGTECH.NET.

2.3 Workshop Safety Equipment

A well-equipped and maintained workshop is essential for safe diagnostic operations.

- Vehicle Lift: Use a properly maintained vehicle lift to safely raise the vehicle for undercarriage inspections. According to the American National Standards Institute (ANSI), vehicle lifts should be inspected annually.

- Wheel Chocks: Secure the vehicle with wheel chocks to prevent movement during diagnostic procedures.

- Fire Extinguisher: Keep aClass ABC fire extinguisher readily accessible in case of electrical or chemical fires.

- Ventilation System: Ensure adequate ventilation to remove harmful fumes and gases.

Alt text: Close-up of safety glasses designed to protect eyes during diagnostic operations

3. Step-by-Step Safety Procedures for Using Xentry

Following a structured set of safety procedures is essential when using Xentry. These procedures help minimize risks and ensure a safe and efficient diagnostic process.

3.1 Pre-Diagnostic Checks

Before starting any diagnostic procedure, perform the following checks:

- Inspect the Vehicle: Look for any visible signs of damage, such as leaks, frayed wires, or broken components.

- Review the Vehicle’s History: Check for any previous repairs or issues that may affect the diagnostic process.

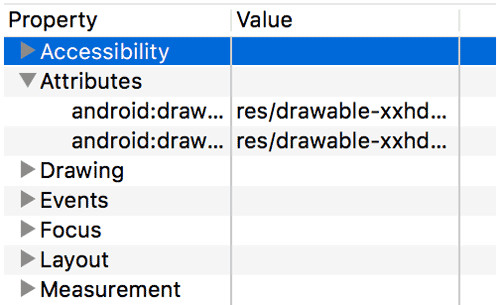

- Verify the Xentry Software: Ensure the Xentry software is up-to-date and properly installed on your diagnostic computer.

- Check Diagnostic Equipment: Verify that all diagnostic tools, including the Xentry interface and multimeter, are functioning correctly.

3.2 Connecting Xentry Safely

Connecting Xentry to the vehicle requires careful attention to avoid electrical damage.

- Turn Off the Ignition: Always turn off the vehicle’s ignition before connecting or disconnecting the Xentry interface.

- Locate the OBD2 Port: Find the OBD2 port, typically located under the dashboard on the driver’s side.

- Connect the Interface: Plug the Xentry interface into the OBD2 port, ensuring a secure connection.

- Power On the Diagnostic Computer: Turn on the diagnostic computer and launch the Xentry software.

- Verify Connection: Confirm that the Xentry software recognizes the vehicle and the interface connection is stable.

3.3 Performing Diagnostic Tests

During diagnostic tests, it’s crucial to follow safety protocols to prevent accidents.

- Follow the Xentry Prompts: Carefully follow the instructions and prompts provided by the Xentry software.

- Monitor Vehicle Systems: Keep a close watch on vehicle systems, such as voltage levels and temperature readings, to detect any anomalies.

- Use a Multimeter: Verify electrical signals with a multimeter to ensure accuracy and safety.

- Avoid Contact with Moving Parts: Keep hands and tools away from moving parts while the engine is running.

3.4 Post-Diagnostic Procedures

After completing diagnostic tests, follow these steps to ensure safety and proper vehicle operation.

- Disconnect Xentry: Safely disconnect the Xentry interface from the OBD2 port after turning off the ignition.

- Clear Diagnostic Trouble Codes: Clear any diagnostic trouble codes (DTCs) that were generated during the diagnostic process.

- Verify Repairs: Confirm that all repairs have been completed successfully and that the vehicle is operating correctly.

- Document Findings: Document all diagnostic findings, repairs, and any other relevant information for future reference.

Alt text: Technician connecting Xentry diagnostic tool to the OBD2 port of a vehicle

4. Electrical Safety Practices

Working with electrical systems poses significant risks. Adhering to electrical safety practices is essential for preventing shocks, burns, and other injuries.

4.1 Understanding Vehicle Electrical Systems

Modern vehicles have complex electrical systems that require careful handling. According to the Society of Automotive Engineers (SAE), understanding the fundamentals of automotive electricity is crucial for safe diagnostic and repair work.

- Voltage Levels: Be aware of the different voltage levels in the vehicle’s electrical system, typically 12V, 24V, and 48V.

- Circuit Types: Understand the different types of circuits, including series, parallel, and combination circuits.

- Wiring Diagrams: Use wiring diagrams to trace circuits and identify components accurately.

4.2 Safe Handling of Electrical Components

Follow these guidelines for safely handling electrical components:

- Disconnect the Battery: Always disconnect the negative terminal of the battery before working on electrical components. This prevents accidental shorts and electrical shocks.

- Use Insulated Tools: Use insulated tools to prevent electrical contact and reduce the risk of shocks.

- Avoid Water: Never work on electrical components in wet or damp conditions.

- Check for Shorts: Use a multimeter to check for shorts before reconnecting components.

- Proper Wiring: Ensure all wiring is properly insulated and routed to prevent chafing and shorts.

4.3 Dealing with High-Voltage Systems

Hybrid and electric vehicles have high-voltage systems that require specialized safety precautions. According to the National Highway Traffic Safety Administration (NHTSA), technicians working on these systems must be properly trained and certified.

- Wear High-Voltage Gloves: Use certified high-voltage gloves to protect against electrical shocks.

- Isolate the High-Voltage System: Follow the manufacturer’s procedures for isolating and disabling the high-voltage system.

- Use Insulated Tools: Use specially designed insulated tools for working on high-voltage components.

- Check for Voltage: Verify that the high-voltage system is completely discharged before starting any work.

5. Chemical Safety Guidelines

Automotive repair shops often contain hazardous chemicals. Proper handling and storage of these chemicals are essential for preventing exposure and accidents.

5.1 Identifying Hazardous Chemicals

Common hazardous chemicals in automotive repair shops include:

- Brake Cleaner: Contains solvents that can cause respiratory irritation and skin damage.

- Battery Acid: Corrosive and can cause severe burns.

- Engine Oil: Contains hydrocarbons that can cause skin irritation and cancer.

- Coolant: Contains ethylene glycol, which is toxic if ingested.

5.2 Safe Handling Practices

Follow these guidelines for safely handling hazardous chemicals:

- Read Safety Data Sheets (SDS): Always read the SDS for each chemical to understand its hazards and safety precautions.

- Use PPE: Wear appropriate PPE, such as gloves, safety glasses, and protective clothing, when handling chemicals.

- Work in a Well-Ventilated Area: Ensure adequate ventilation to prevent inhalation of harmful fumes.

- Avoid Mixing Chemicals: Never mix chemicals unless specifically instructed to do so, as this can create dangerous reactions.

- Proper Labeling: Ensure all chemical containers are properly labeled with the chemical name and hazard warnings.

5.3 Proper Storage and Disposal

Proper storage and disposal of hazardous chemicals are crucial for preventing accidents and environmental contamination.

- Store Chemicals in Designated Areas: Store chemicals in a designated area away from heat, sparks, and open flames.

- Use Approved Containers: Store chemicals in approved containers that are compatible with the chemical being stored.

- Dispose of Waste Properly: Dispose of chemical waste according to local, state, and federal regulations. Contact a certified waste disposal company for assistance.

- Spill Control: Keep spill control materials, such as absorbent pads and booms, readily available in case of spills.

Alt text: Technician wearing chemical-resistant gloves while handling automotive fluids

6. Physical Safety and Ergonomics

Performing diagnostic operations can be physically demanding. Following ergonomic principles and practicing physical safety can help prevent injuries and improve overall well-being.

6.1 Proper Lifting Techniques

Lifting heavy objects incorrectly can lead to back injuries and other musculoskeletal disorders.

- Assess the Load: Before lifting an object, assess its weight and size.

- Use Proper Posture: Keep your back straight, bend your knees, and maintain a wide base of support.

- Lift with Your Legs: Use your leg muscles to lift the object, keeping it close to your body.

- Avoid Twisting: Avoid twisting your body while lifting or carrying the object.

- Get Help: If the object is too heavy or awkward to lift alone, ask for assistance.

6.2 Ergonomic Workstation Setup

An ergonomically designed workstation can help reduce strain and fatigue.

- Adjustable Work Surface: Use an adjustable work surface to set the appropriate height for your task.

- Comfortable Seating: Use a comfortable chair with good lumbar support.

- Proper Lighting: Ensure adequate lighting to reduce eye strain.

- Tool Placement: Keep frequently used tools within easy reach to avoid unnecessary stretching and bending.

- Regular Breaks: Take regular breaks to stretch and move around to prevent stiffness and fatigue.

6.3 Preventing Slip, Trip, and Fall Hazards

Slips, trips, and falls are common causes of workplace injuries.

- Keep Floors Clean and Dry: Clean up spills immediately and keep floors free of debris.

- Use Non-Slip Footwear: Wear non-slip footwear to improve traction.

- Proper Lighting: Ensure adequate lighting to identify hazards.

- Mark Hazards: Use cones or barriers to mark potential hazards, such as wet floors or uneven surfaces.

- Proper Housekeeping: Keep walkways clear of obstacles and clutter.

7. Emergency Procedures

Knowing how to respond in an emergency is critical for minimizing harm and protecting lives.

7.1 First Aid Basics

Basic first aid knowledge can help you respond effectively to injuries until professional medical help arrives.

- CPR: Learn how to perform cardiopulmonary resuscitation (CPR) in case of cardiac arrest.

- Wound Care: Know how to clean and dress wounds to prevent infection.

- Burn Treatment: Understand how to treat burns, including cooling the burn with water and covering it with a sterile dressing.

- Chemical Exposure: Know how to flush chemicals from the eyes or skin and seek medical attention.

- Electrical Shock: Know how to safely disconnect the power source and provide first aid for electrical shock.

7.2 Fire Safety

Knowing how to prevent and respond to fires is essential for protecting lives and property.

- Fire Prevention: Follow fire prevention practices, such as properly storing flammable materials and maintaining electrical equipment.

- Fire Extinguisher Use: Learn how to use a fire extinguisher effectively. Remember the acronym PASS: Pull, Aim, Squeeze, Sweep.

- Evacuation Plan: Know the evacuation plan for your workplace and practice regular fire drills.

- Smoke Detectors: Ensure smoke detectors are installed and functioning properly.

7.3 Reporting Accidents and Incidents

Reporting accidents and incidents is crucial for identifying hazards and preventing future occurrences.

- Report All Incidents: Report all accidents and incidents, no matter how minor, to your supervisor or safety officer.

- Document Details: Document the details of the incident, including the date, time, location, and description of what happened.

- Investigate Causes: Investigate the causes of the incident to identify contributing factors and prevent future occurrences.

- Implement Corrective Actions: Implement corrective actions to address the identified hazards and improve safety procedures.

8. Regular Training and Certification

Continuous training and certification are essential for maintaining a high level of safety and competence.

8.1 Importance of Continuous Education

The automotive industry is constantly evolving, with new technologies and diagnostic procedures being introduced regularly. Continuous education is essential for technicians to stay current with these changes and maintain a safe working environment.

8.2 Available Training Programs

There are many training programs available for automotive technicians, including:

- ASE Certification: Automotive Service Excellence (ASE) certification is a widely recognized standard of competence in the automotive industry.

- Manufacturer-Specific Training: Many manufacturers, such as Mercedes-Benz, offer specialized training programs for their vehicles and diagnostic tools.

- Online Courses: Online courses provide a convenient and flexible way to learn new skills and stay current with industry trends.

8.3 Certification Requirements

Certification requirements vary depending on the specific program. However, most programs require a combination of education, experience, and passing an exam.

Alt text: Automotive technician participating in a training session on vehicle diagnostics

9. Maintaining a Safe Workshop Environment

A well-organized and maintained workshop is essential for safety and efficiency.

9.1 Housekeeping Practices

Good housekeeping practices can help prevent accidents and improve overall safety.

- Keep Work Areas Clean and Organized: Keep work areas free of clutter and debris.

- Proper Storage: Store tools and equipment in designated areas when not in use.

- Clean Up Spills Immediately: Clean up spills immediately to prevent slips and falls.

- Waste Disposal: Dispose of waste properly according to local, state, and federal regulations.

9.2 Regular Equipment Inspections

Regular equipment inspections can help identify potential hazards and prevent accidents.

- Inspect Tools: Inspect tools regularly for damage or wear.

- Check Electrical Cords: Check electrical cords for fraying or damage.

- Maintain Vehicle Lifts: Inspect vehicle lifts regularly and perform maintenance as needed.

- Calibrate Diagnostic Equipment: Calibrate diagnostic equipment regularly to ensure accuracy.

9.3 Safety Audits

Regular safety audits can help identify potential hazards and improve safety procedures.

- Conduct Regular Audits: Conduct regular safety audits to identify potential hazards and assess safety practices.

- Involve Employees: Involve employees in the audit process to get their input and perspective.

- Implement Corrective Actions: Implement corrective actions to address the identified hazards and improve safety procedures.

- Document Findings: Document the findings of the audit and the corrective actions taken.

10. Leveraging CARDIAGTECH.NET for Diagnostic Tool Needs

For technicians and shop owners looking to enhance their diagnostic capabilities and ensure safety, CARDIAGTECH.NET offers a wide range of high-quality diagnostic tools and equipment.

10.1 High-Quality Diagnostic Tools

CARDIAGTECH.NET provides access to top-of-the-line diagnostic tools, including Xentry interfaces, OBD2 scanners, multimeters, and battery testers. These tools are sourced from reputable manufacturers and are designed to provide accurate and reliable results.

10.2 Expert Advice and Support

The team at CARDIAGTECH.NET is comprised of experienced professionals who can provide expert advice and support to help you choose the right tools for your needs. They can also provide guidance on how to use the tools safely and effectively.

10.3 Convenient Online Shopping

CARDIAGTECH.NET offers a convenient online shopping experience, allowing you to browse and purchase diagnostic tools from the comfort of your own home or shop. With fast shipping and secure payment options, you can get the tools you need quickly and easily.

10.4 Commitment to Safety

CARDIAGTECH.NET is committed to promoting safety in the automotive repair industry. By providing high-quality diagnostic tools and expert advice, they help technicians and shop owners create a safer and more efficient working environment.

FAQ: Ensuring Safety with Xentry Diagnostic Operations

Q1: What is Xentry, and why is it important to use it safely?

A: Xentry is a comprehensive diagnostic tool for Mercedes-Benz vehicles. It’s crucial to use it safely to protect yourself, your equipment, and the vehicle’s systems from damage.

Q2: What PPE should I wear when using Xentry for diagnostic operations?

A: Essential PPE includes safety glasses, insulated gloves, protective clothing, and steel-toed boots to safeguard against electrical shocks, chemical exposure, and physical injuries.

Q3: How often should I inspect my diagnostic equipment?

A: Diagnostic equipment should be inspected regularly, ideally before each use, to ensure it’s in good working condition and properly calibrated for accurate results.

Q4: What should I do if I encounter a high-voltage system in a vehicle?

A: Use certified high-voltage gloves, isolate the high-voltage system following manufacturer procedures, and verify the system is completely discharged before working on it.

Q5: How should I handle hazardous chemicals in the workshop?

A: Always read Safety Data Sheets (SDS), use appropriate PPE, work in a well-ventilated area, avoid mixing chemicals, and ensure proper labeling and storage in approved containers.

Q6: What are the key steps to proper lifting techniques to avoid injuries?

A: Assess the load, maintain proper posture (straight back, bent knees), lift with your legs, avoid twisting, and seek help if the object is too heavy or awkward to handle alone.

Q7: What basic first aid knowledge should I have in the workshop?

A: You should know CPR, wound care, burn treatment, how to flush chemicals from eyes or skin, and how to safely handle electrical shock incidents.

Q8: How can I maintain a safe workshop environment?

A: Implement good housekeeping practices, conduct regular equipment inspections, perform safety audits, and involve employees in identifying and addressing potential hazards.

Q9: Why is continuous education important for automotive technicians?

A: Continuous education keeps technicians updated on new technologies and diagnostic procedures, ensuring they maintain a high level of competence and safety.

Q10: Where can I find high-quality diagnostic tools and expert advice for my automotive shop?

A: CARDIAGTECH.NET offers a wide range of high-quality diagnostic tools, expert advice, and convenient online shopping to help enhance your diagnostic capabilities and ensure safety. Contact them at +1 (641) 206-8880 or visit 276 Reock St, City of Orange, NJ 07050, United States.

Take Action for a Safer Diagnostic Environment

Ready to enhance your safety while performing diagnostic operations with Xentry? Here’s how CARDIAGTECH.NET can help:

- Explore Top-Quality Tools: Visit CARDIAGTECH.NET to discover our range of diagnostic tools and equipment designed for safety and accuracy.

- Get Expert Guidance: Contact us for personalized advice on selecting the right tools for your specific needs and how to use them safely.

- Convenient Shopping: Enjoy a seamless online shopping experience with fast shipping and secure payment options.

Don’t wait! Upgrade your diagnostic capabilities and ensure a safer working environment today.

Call us now at +1 (641) 206-8880 to speak with our experts or visit our store at 276 Reock St, City of Orange, NJ 07050, United States. Let CARDIAGTECH.NET be your partner in safety and excellence.

By following these guidelines and leveraging the resources available at CARDIAGTECH.NET, you can create a safer and more efficient diagnostic environment, protecting yourself and your equipment while delivering exceptional service to your customers.