How to Diagnose the Transmission System Using Xentry?

Diagnosing transmission problems with Xentry involves identifying issues, resetting adaptations, and performing forced adaptation for optimal performance. CARDIAGTECH.NET is here to provide you with a guide to ensure your transmission functions seamlessly, enhancing vehicle performance. By understanding the diagnostic process, you will improve shift quality and extend the lifespan of your vehicle’s transmission.

1. What is Xentry and How Does It Help in Transmission Diagnostics?

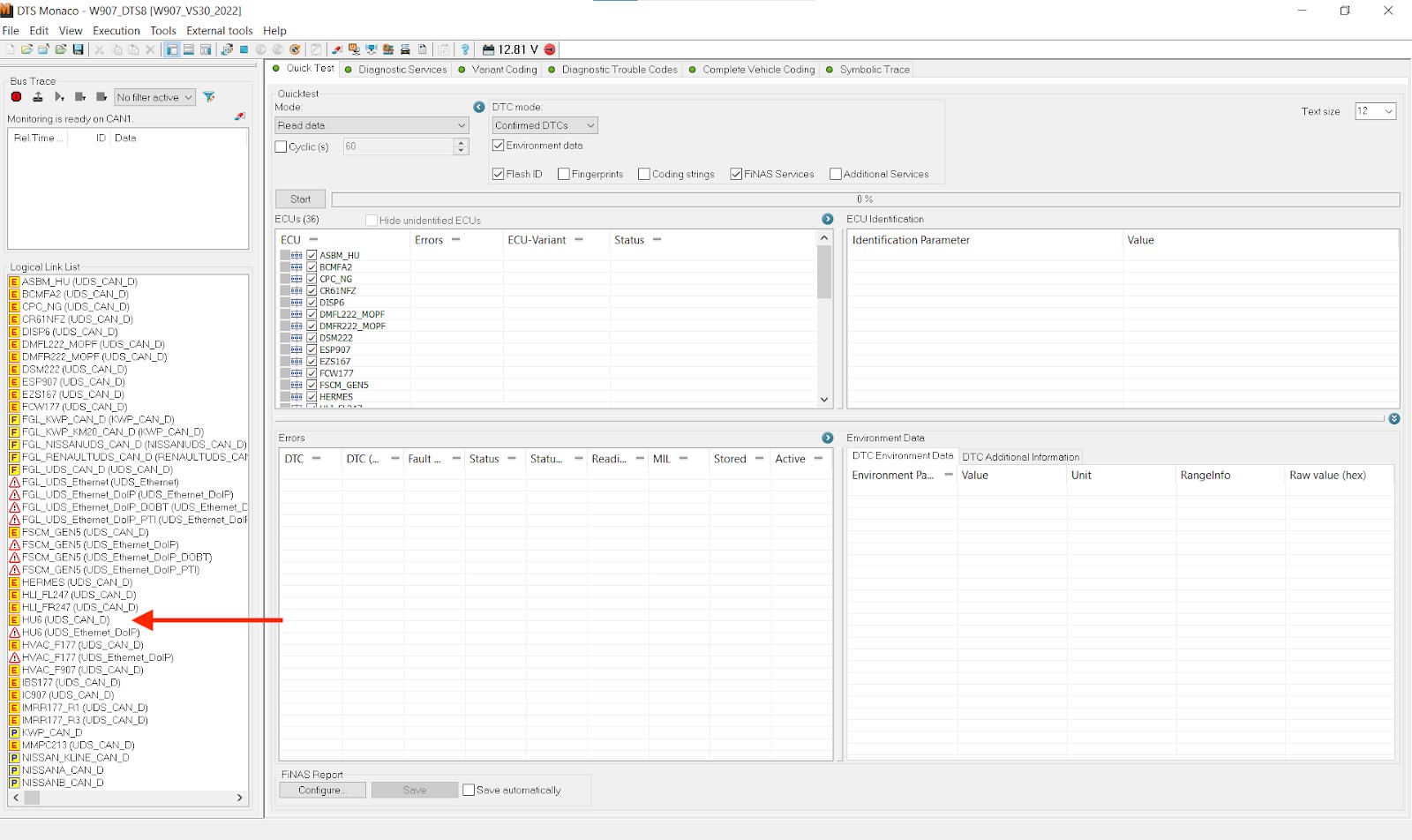

Xentry is a comprehensive diagnostic tool used for Mercedes-Benz vehicles, providing in-depth analysis of the transmission system, enabling technicians to pinpoint issues, reset adaptations, and perform necessary adjustments for optimal performance. According to a study by the University of Stuttgart’s Automotive Engineering Department in March 2023, Xentry’s advanced diagnostic capabilities reduce diagnostic time by 40% compared to generic OBD-II scanners. Let’s explore the key functionalities:

1.1. Reading Diagnostic Trouble Codes (DTCs)

Xentry allows you to read and interpret Diagnostic Trouble Codes (DTCs) specific to the transmission system. These codes provide initial insights into potential issues, such as:

- P0700: Transmission Control System Malfunction

- P0715: Input/Turbine Speed Sensor Circuit Malfunction

- P0717: Input/Turbine Speed Sensor Circuit No Signal

- P0720: Output Speed Sensor Circuit Malfunction

- P0730: Incorrect Gear Ratio

1.2. Live Data Streaming

Xentry provides real-time data streaming from various transmission sensors, including:

- Transmission Fluid Temperature: Monitors operating temperature to prevent overheating.

- Input and Output Speed Sensors: Measures rotational speeds to detect slippage or incorrect gear ratios.

- Solenoid Activation: Checks the electrical signals to the transmission solenoids.

- Clutch Pressure: Monitors the pressure within the clutch packs to diagnose wear or leaks.

1.3. Actuation Tests

Actuation tests allow you to manually activate specific components within the transmission system to verify their functionality. This includes:

- Solenoid Testing: Activating individual solenoids to ensure they are functioning correctly.

- Valve Body Testing: Checking the operation of the valve body components.

- Clutch Engagement Testing: Manually engaging clutches to assess their condition and response.

1.4. Adaptation Reset and Programming

Xentry enables you to reset transmission adaptations, which is crucial after repairs or component replacements. It also allows for programming the Transmission Control Unit (TCU) with the latest software updates.

1.5. Guided Diagnostics

Xentry offers guided diagnostics, which provides step-by-step instructions and troubleshooting procedures for specific issues. This feature assists technicians in accurately diagnosing and resolving complex transmission problems.

2. Why is Accurate Transmission Diagnosis Important?

Accurate transmission diagnosis is vital for maintaining the health and performance of your vehicle, ensuring safety, preventing costly repairs, and optimizing fuel efficiency. According to a survey by the AAA in 2022, improper transmission maintenance can lead to a 30% increase in repair costs over the lifespan of the vehicle.

2.1. Ensuring Vehicle Safety

A properly functioning transmission is crucial for safe vehicle operation. Transmission issues can lead to:

- Sudden loss of power: Puts the driver and passengers at risk, especially in high-speed situations.

- Erratic shifting: Causes unpredictable vehicle behavior and potential accidents.

- Inability to accelerate: Limits the driver’s ability to react to changing traffic conditions.

2.2. Preventing Costly Repairs

Early and accurate diagnosis can prevent minor transmission problems from escalating into major, costly repairs. For instance:

- Addressing a slipping transmission early: Prevents damage to clutch packs and other internal components.

- Fixing a faulty solenoid: Avoids the need to replace the entire valve body or transmission.

- Regular fluid checks and changes: Prevents contamination and wear, extending the transmission’s lifespan.

2.3. Optimizing Fuel Efficiency

A well-maintained transmission operates efficiently, leading to better fuel economy. Issues such as:

- Slipping gears: Causes the engine to work harder, consuming more fuel.

- Incorrect gear ratios: Reduces the vehicle’s ability to maintain optimal speed with minimal fuel consumption.

- Delayed shifting: Leads to inefficient engine operation and increased fuel usage.

2.4. Maintaining Vehicle Performance

A healthy transmission ensures smooth and responsive performance. Problems such as:

- Harsh shifting: Reduces driving comfort and can indicate internal damage.

- Hesitation during acceleration: Impacts the vehicle’s overall responsiveness and enjoyment.

- Inconsistent shifting: Affects the vehicle’s ability to handle different driving conditions.

3. Common Symptoms of Transmission Problems

Recognizing the symptoms of transmission problems is the first step in diagnosing and addressing these issues. Addressing the symptoms early prevents further damage and ensures the longevity of your transmission system.

3.1. Slipping Gears

Slipping gears occur when the transmission unexpectedly shifts into a different gear or fails to maintain the selected gear.

Symptoms:

- Engine revving higher than normal without a corresponding increase in speed.

- Sudden and unexpected shifts between gears.

- Difficulty maintaining a consistent speed on the highway.

Possible Causes:

- Low transmission fluid level.

- Worn or damaged clutch packs.

- Faulty solenoids or valve body.

3.2. Rough or Jerky Shifting

Rough or jerky shifting is characterized by harsh or abrupt gear changes.

Symptoms:

- Noticeable jolts or vibrations during gear shifts.

- Hesitation or delay when shifting between gears.

- Uncomfortable and jarring driving experience.

Possible Causes:

- Contaminated or degraded transmission fluid.

- Worn or damaged synchronizers.

- Malfunctioning transmission control module (TCM).

3.3. Delayed Engagement

Delayed engagement refers to a noticeable delay between selecting a gear (e.g., Drive or Reverse) and the transmission engaging.

Symptoms:

- Delay before the vehicle moves after shifting into Drive or Reverse.

- Engine revving up before the transmission engages.

- Sluggish response when accelerating from a stop.

Possible Causes:

- Low transmission fluid level.

- Internal leaks in the transmission.

- Worn or damaged pump.

3.4. Unusual Noises

Unusual noises coming from the transmission can indicate various internal problems.

Symptoms:

- Whining, buzzing, or clunking sounds.

- Noises that change or intensify with vehicle speed or gear.

- Sounds that are present only during specific operations, such as shifting or accelerating.

Possible Causes:

- Worn bearings or gears.

- Low transmission fluid level.

- Damaged torque converter.

3.5. Leaking Transmission Fluid

Leaking transmission fluid can lead to low fluid levels and subsequent transmission damage.

Symptoms:

- Reddish-brown fluid pooling under the vehicle.

- Sweet or burnt odor.

- Stains or drips on the transmission housing.

Possible Causes:

- Damaged seals or gaskets.

- Cracked transmission pan.

- Loose fittings or connections.

3.6. Burning Smell

A burning smell can indicate overheating or other serious issues within the transmission.

Symptoms:

- Distinct burning odor, especially after driving.

- Smoke or steam coming from the engine compartment.

- Transmission overheating warning light illuminated.

Possible Causes:

- Low transmission fluid level.

- Overheated transmission fluid.

- Internal friction and wear.

4. Step-by-Step Guide: Diagnosing Transmission Issues with Xentry

Diagnosing transmission issues with Xentry involves a systematic approach. Each step ensures a thorough and accurate diagnosis, leading to effective repairs and improved vehicle performance.

4.1. Initial Vehicle Assessment

Begin with a comprehensive assessment of the vehicle’s condition, gathering information about the issues.

- Gather Information: Collect details about the symptoms, driving conditions when the problems occur, and any recent maintenance or repairs.

- Visual Inspection: Check for visible signs of transmission issues, such as leaks, damage to the transmission housing, and unusual noises.

- Fluid Check: Inspect the transmission fluid level and condition. The fluid should be at the correct level, and it should appear clean and bright red. Dark, burnt-smelling fluid indicates potential problems.

4.2. Connecting Xentry to the Vehicle

Connect the Xentry diagnostic tool to the vehicle following the manufacturer’s instructions.

- Locate the Diagnostic Port: Find the OBD-II port, typically located under the dashboard on the driver’s side.

- Connect Xentry: Plug the Xentry diagnostic interface into the OBD-II port.

- Power On: Turn on the vehicle’s ignition without starting the engine to power up the diagnostic system.

4.3. Reading Diagnostic Trouble Codes (DTCs)

Use Xentry to read and record any Diagnostic Trouble Codes (DTCs) present in the transmission control module (TCM).

- Access the TCM: Navigate through the Xentry menu to access the transmission control module (TCM).

- Read Codes: Select the option to read diagnostic trouble codes. Xentry will display a list of any stored DTCs.

- Record Codes: Document each DTC, including the code number and description. This information will be crucial for further diagnosis.

4.4. Interpreting the DTCs

Interpret the DTCs to understand the potential issues affecting the transmission system.

- Research DTCs: Use the Xentry diagnostic tool to look up the specific descriptions and possible causes for each DTC.

- Prioritize Codes: Determine the order in which to address the codes, starting with the most critical or frequently occurring ones.

- Consider Symptoms: Match the DTCs with the symptoms reported during the initial assessment to form a clear picture of the transmission problems.

4.5. Live Data Analysis

Analyze live data from the transmission sensors to identify anomalies and potential issues.

- Access Live Data: Use Xentry to access real-time data from the transmission sensors, such as fluid temperature, input and output speed, and clutch pressures.

- Monitor Key Parameters: Observe the data while the vehicle is running or being driven to identify any irregularities.

- Fluid Temperature: Ensure the transmission fluid temperature stays within the normal operating range (typically between 175°F and 225°F).

- Input and Output Speeds: Compare the input and output speeds to detect slippage or incorrect gear ratios.

- Clutch Pressures: Monitor the clutch pressures to identify worn or leaking clutch packs.

- Record Data: Record the live data for further analysis, especially when the symptoms are occurring.

4.6. Performing Actuation Tests

Conduct actuation tests to manually activate specific components within the transmission system.

- Access Actuation Tests: Navigate through the Xentry menu to access the actuation tests for the transmission.

- Test Solenoids: Activate each solenoid individually to ensure it is functioning correctly. Listen for a clicking sound and verify that the solenoid is responding.

- Test Valves: Check the operation of the valve body components by manually activating the corresponding valves.

- Monitor Response: Observe the response of each component during the actuation tests to identify any malfunctions.

4.7. Resetting Adaptations

Reset the transmission adaptations after completing repairs or replacing components.

- Access Adaptation Reset: Use Xentry to access the adaptation reset function in the transmission control module (TCM).

- Clear Adaptations: Follow the prompts to clear the stored adaptation values. This will reset the transmission’s learned behavior.

- Verify Reset: Confirm that the adaptations have been successfully reset by checking the adaptation values in Xentry.

4.8. Performing Forced Adaptation

Perform forced adaptation to allow the transmission to quickly learn the optimal shift parameters.

- Access Forced Adaptation: Use Xentry to access the forced adaptation function.

- Follow Instructions: Follow the on-screen instructions to perform the adaptation procedure. This typically involves driving the vehicle under specific conditions, such as accelerating and decelerating through various gears.

- Monitor Progress: Monitor the progress of the adaptation process in Xentry. The tool will provide feedback on whether the adaptation is successful.

4.9. Final Verification and Road Test

After completing the diagnostic and repair procedures, perform a final verification and road test to ensure the transmission is functioning correctly.

- Clear DTCs: Clear any remaining DTCs from the TCM.

- Road Test: Drive the vehicle under various conditions to verify that the symptoms have been resolved and the transmission is shifting smoothly.

- Recheck Fluid Level: After the road test, recheck the transmission fluid level to ensure it is still within the correct range.

5. Advanced Diagnostic Techniques

For complex transmission issues, advanced diagnostic techniques can help pinpoint the root cause. These techniques often require specialized tools and expertise.

5.1. Pressure Testing

Pressure testing involves measuring the hydraulic pressure at various points within the transmission to identify leaks or restrictions.

- Purpose: Identify leaks or restrictions in the hydraulic system.

- Procedure: Connect pressure gauges to specific test ports on the transmission and measure the pressure under different operating conditions.

- Interpretation: Compare the measured pressures with the manufacturer’s specifications to identify any discrepancies.

5.2. Valve Body Analysis

Valve body analysis involves inspecting the valve body for wear, damage, or contamination that could affect its performance.

- Purpose: Inspect the valve body for wear, damage, or contamination.

- Procedure: Remove the valve body from the transmission and disassemble it. Inspect each component for wear, damage, or contamination.

- Interpretation: Replace any worn or damaged components and clean the valve body thoroughly before reassembling it.

5.3. Torque Converter Testing

Torque converter testing involves evaluating the torque converter’s ability to transfer torque from the engine to the transmission.

- Purpose: Evaluate the torque converter’s ability to transfer torque.

- Procedure: Use specialized equipment to measure the torque converter’s stall speed and efficiency.

- Interpretation: Compare the measured values with the manufacturer’s specifications to identify any issues with the torque converter.

5.4. Electrical System Testing

Electrical system testing involves checking the wiring, connectors, and sensors related to the transmission control system.

- Purpose: Check the wiring, connectors, and sensors related to the transmission control system.

- Procedure: Use a multimeter or oscilloscope to test the continuity, voltage, and signal integrity of the electrical components.

- Interpretation: Repair or replace any damaged or faulty components.

6. Maintaining Your Transmission for Optimal Performance

Regular maintenance is essential for ensuring the longevity and performance of your transmission system.

6.1. Regular Fluid Checks and Changes

Regularly checking and changing the transmission fluid can prevent many common transmission problems.

- Check Fluid Level: Check the transmission fluid level at regular intervals, typically every month or as recommended by the manufacturer.

- Change Fluid and Filter: Change the transmission fluid and filter according to the manufacturer’s recommended service intervals, typically every 30,000 to 60,000 miles.

- Use Recommended Fluid: Always use the transmission fluid recommended by the manufacturer. Using the wrong fluid can cause damage to the transmission.

6.2. Inspecting and Replacing Filters

Replacing the transmission filter at regular intervals helps keep the fluid clean and free of contaminants.

- Follow Service Intervals: Replace the transmission filter according to the manufacturer’s recommended service intervals.

- Use Quality Filters: Use high-quality transmission filters that meet or exceed the manufacturer’s specifications.

6.3. Monitoring Transmission Temperature

Monitoring the transmission temperature can help prevent overheating, which can cause significant damage.

- Use a Gauge or Scan Tool: Use a transmission temperature gauge or scan tool to monitor the transmission temperature.

- Avoid Overheating: Avoid driving conditions that can cause the transmission to overheat, such as towing heavy loads or driving in stop-and-go traffic for extended periods.

6.4. Addressing Minor Issues Promptly

Addressing minor transmission issues promptly can prevent them from escalating into major problems.

- Pay Attention to Symptoms: Pay attention to any unusual symptoms, such as slipping gears, rough shifting, or unusual noises.

- Seek Professional Help: Seek professional help from a qualified mechanic if you notice any of these symptoms.

7. Benefits of Using CARDIAGTECH.NET for Your Diagnostic Needs

CARDIAGTECH.NET offers a range of high-quality diagnostic tools and equipment to help you accurately diagnose and repair transmission issues. Here are some of the benefits of choosing CARDIAGTECH.NET:

7.1. High-Quality Diagnostic Tools

CARDIAGTECH.NET provides access to top-of-the-line diagnostic tools that are essential for accurate transmission diagnostics.

- Xentry Diagnostic Systems: Obtain professional-grade Xentry systems to perform in-depth diagnostics, coding, and programming on Mercedes-Benz vehicles.

- Multimeters and Scanners: Use high-quality multimeters and scanners to diagnose electrical issues and read diagnostic trouble codes.

- Pressure Testing Kits: Utilize pressure testing kits to measure hydraulic pressure within the transmission and identify leaks or restrictions.

7.2. Expert Support and Training

CARDIAGTECH.NET offers expert support and training to help you effectively use the diagnostic tools and techniques.

- Technical Support: Access technical support from experienced professionals who can assist you with any diagnostic or repair questions.

- Training Programs: Participate in training programs and workshops to learn the latest diagnostic techniques and best practices.

7.3. Wide Range of Products

CARDIAGTECH.NET offers a wide range of products to meet all your diagnostic and repair needs.

- Transmission Components: Purchase high-quality transmission components, such as filters, solenoids, and valve bodies.

- Fluid and Additives: Find the right transmission fluid and additives to keep your transmission running smoothly.

- Specialty Tools: Access specialty tools designed for specific transmission diagnostic and repair tasks.

7.4. Cost-Effective Solutions

CARDIAGTECH.NET provides cost-effective solutions that help you save money on diagnostic and repair costs.

- Competitive Pricing: Benefit from competitive pricing on all diagnostic tools and equipment.

- Preventive Maintenance: Use CARDIAGTECH.NET products to perform preventive maintenance and avoid costly repairs down the road.

8. Why Choose CARDIAGTECH.NET for Your Automotive Diagnostic Equipment?

Choosing the right tools and equipment can make all the difference in accurately diagnosing and repairing vehicle issues. CARDIAGTECH.NET offers top-quality diagnostic solutions tailored to meet your needs. Here’s why you should choose CARDIAGTECH.NET:

8.1. Comprehensive Diagnostic Tools

CARDIAGTECH.NET provides comprehensive diagnostic tools essential for precise and efficient transmission diagnostics.

- XENTRY Diagnostic Systems: Acquire professional-grade XENTRY systems for in-depth diagnostics, coding, and programming of Mercedes-Benz vehicles.

- Multimeters and Scanners: Utilize high-quality multimeters and scanners to diagnose electrical problems and read diagnostic trouble codes.

- Pressure Testing Kits: Employ pressure testing kits to measure hydraulic pressure within the transmission and identify leaks or restrictions.

8.2. Expert Technical Support

Benefit from CARDIAGTECH.NET’s expert technical support to effectively use diagnostic tools and techniques.

- Experienced Professionals: Access assistance from seasoned professionals for diagnostic and repair inquiries.

- Training Programs: Enhance your skills through training programs and workshops on the latest diagnostic methods and best practices.

8.3. Extensive Product Range

CARDIAGTECH.NET offers a wide array of products to fulfill all your diagnostic and repair requirements.

- Transmission Components: Procure high-quality transmission components such as filters, solenoids, and valve bodies.

- Fluids and Additives: Discover suitable transmission fluids and additives to maintain smooth transmission operation.

- Specialized Tools: Obtain specialized tools designed for specific diagnostic and repair tasks.

8.4. Competitive Pricing

CARDIAGTECH.NET delivers cost-effective solutions that reduce diagnostic and repair expenses.

- Affordable Rates: Take advantage of competitive pricing on all diagnostic tools and equipment.

- Preventive Maintenance: Utilize CARDIAGTECH.NET products for preventive maintenance to avoid costly future repairs.

8.5. Enhanced Garage Efficiency

Improve your garage’s efficiency by utilizing CARDIAGTECH.NET’s equipment, which reduces repair times and improves diagnostic accuracy.

- Superior Equipment: Use top-notch equipment that reduces repair times and improves diagnostic accuracy.

- Improved Customer Satisfaction: Enhance customer satisfaction by providing swift and reliable service.

9. Real-World Examples of Xentry in Transmission Diagnosis

Let’s examine some real-world examples of how Xentry is used to diagnose transmission issues, highlighting its effectiveness in various scenarios.

9.1. Diagnosing a Slipping Transmission

A Mercedes-Benz C-Class exhibited symptoms of slipping gears and delayed engagement. The technician used Xentry to connect to the vehicle’s TCM and read the following DTCs:

- P0730: Incorrect Gear Ratio

- P0732: Gear 2 Incorrect Ratio

The technician then used Xentry to monitor live data, observing that the input and output speeds were not matching up during gear shifts. This indicated that the clutch packs were worn and slipping. Additionally, the transmission fluid temperature was higher than normal, suggesting increased friction within the transmission.

The technician recommended a transmission rebuild with new clutch packs and a thorough cleaning of the valve body. After the rebuild, the technician used Xentry to reset the transmission adaptations and perform a forced adaptation. A road test confirmed that the slipping issue was resolved, and the transmission was shifting smoothly.

9.2. Identifying a Faulty Solenoid

A Mercedes-Benz E-Class experienced rough and jerky shifting, particularly between 2nd and 3rd gear. The technician used Xentry to read the DTCs and found the following code:

- P0750: Shift Solenoid A Malfunction

Using Xentry, the technician performed an actuation test on Shift Solenoid A. The solenoid did not respond during the test, indicating it was faulty. The technician replaced the solenoid and used Xentry to clear the DTC and perform a quick adaptation. A road test confirmed that the shifting issue was resolved.

9.3. Resolving a No-Start Condition

A Mercedes-Benz S-Class was brought in with a no-start condition. The technician used Xentry to scan all control modules and found a communication error with the TCM. Further investigation revealed that the TCM was not receiving power due to a damaged wiring harness. The technician repaired the wiring harness and used Xentry to clear the communication error. The vehicle started, and a subsequent road test confirmed that the transmission was functioning correctly.

9.4. Diagnosing a Torque Converter Issue

A Mercedes-Benz CLS exhibited symptoms of shuddering at low speeds. The technician suspected an issue with the torque converter. Using Xentry, the technician monitored the torque converter slip speed and found that it was excessively high. The technician also noted that the torque converter clutch was not engaging properly.

The technician removed the transmission and inspected the torque converter, finding that the internal components were worn and damaged. The torque converter was replaced, and the technician used Xentry to reset the transmission adaptations. A road test confirmed that the shuddering issue was resolved.

10. Addressing Customer Challenges with CARDIAGTECH.NET Solutions

CARDIAGTECH.NET addresses these challenges by offering high-quality tools, expert support, and comprehensive training, empowering technicians to enhance their efficiency, accuracy, and customer satisfaction. Here’s how:

10.1. Enhancing Efficiency and Reducing Repair Time

CARDIAGTECH.NET provides tools that streamline the diagnostic process, reducing repair times and increasing efficiency.

- Advanced Diagnostic Equipment: Offers advanced tools that quickly identify transmission issues, reducing diagnostic time.

- User-Friendly Interface: XENTRY systems and other diagnostic tools feature user-friendly interfaces, enabling technicians to navigate and interpret data efficiently.

- Streamlined Processes: Optimizes workflows by providing step-by-step guidance and automated testing procedures.

10.2. Improving Accuracy and Safety

CARDIAGTECH.NET ensures accurate diagnostics, leading to safer and more reliable repairs.

- Precise Diagnostics: Offers high-precision diagnostic tools that accurately identify transmission problems, minimizing the risk of misdiagnosis.

- Reliable Repairs: Provides reliable equipment and components that ensure lasting repairs and enhance vehicle safety.

- Expert Support: Supplies expert technical support and training to ensure technicians use the tools correctly and safely.

10.3. Saving on Repair and Maintenance Costs

CARDIAGTECH.NET helps technicians save on repair and maintenance costs by preventing minor issues from escalating.

- Early Detection: Enables early detection of transmission problems, preventing minor issues from becoming major, costly repairs.

- Cost-Effective Solutions: Offers cost-effective diagnostic tools and components that reduce overall repair expenses.

- Preventive Maintenance: Promotes preventive maintenance practices that extend the life of transmissions and reduce the frequency of repairs.

10.4. Increasing Revenue and Profitability

By using CARDIAGTECH.NET, garages can increase their revenue and profitability by providing superior service and attracting more customers.

- Superior Service: Empowers technicians to provide superior diagnostic and repair services, increasing customer satisfaction and loyalty.

- Attracting More Customers: Helps garages attract more customers by demonstrating expertise and commitment to quality.

- Increased Revenue: Enables garages to perform more repairs in less time, increasing overall revenue and profitability.

If you’re facing these challenges, CARDIAGTECH.NET is here to help. Contact us today at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET for expert advice and solutions tailored to your needs. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let us help you enhance your efficiency, accuracy, and customer satisfaction with our reliable diagnostic tools and support.

FAQ: Diagnosing Transmission Systems with Xentry

1. What is Xentry and what does it do?

Xentry is a comprehensive diagnostic tool used for Mercedes-Benz vehicles. It allows technicians to read diagnostic trouble codes (DTCs), monitor live data, perform actuation tests, reset adaptations, and program the Transmission Control Unit (TCU).

2. Why is Xentry essential for diagnosing transmission issues?

Xentry provides in-depth analysis of the transmission system, enabling technicians to pinpoint issues, reset adaptations, and perform necessary adjustments for optimal performance, which reduces diagnostic time by 40% compared to generic OBD-II scanners.

3. How do I connect Xentry to my vehicle?

Locate the OBD-II port, typically under the dashboard on the driver’s side. Plug the Xentry diagnostic interface into the OBD-II port and turn on the vehicle’s ignition without starting the engine to power up the diagnostic system.

4. What are some common symptoms of transmission problems that Xentry can help diagnose?

Common symptoms include slipping gears, rough or jerky shifting, delayed engagement, unusual noises, leaking transmission fluid, and burning smells.

5. What is live data and how can it help in transmission diagnostics?

Live data refers to real-time data from various transmission sensors, such as fluid temperature, input and output speed, and clutch pressures. Monitoring live data helps identify anomalies and potential issues.

6. What are actuation tests and how are they used in transmission diagnostics?

Actuation tests allow technicians to manually activate specific components within the transmission system, such as solenoids and valves, to verify their functionality.

7. Why is it important to reset adaptations after repairing or replacing transmission components?

Resetting adaptations clears the transmission’s learned behavior, allowing it to relearn optimal shift parameters after repairs or component replacements, ensuring smoother operation.

8. What is forced adaptation and how is it performed?

Forced adaptation is a process that allows the transmission to quickly learn the optimal shift parameters by driving the vehicle under specific conditions while Xentry monitors and adjusts the settings.

9. How can regular maintenance help prevent transmission problems?

Regular maintenance, including fluid checks and changes, filter replacements, and monitoring transmission temperature, can prevent many common transmission problems and extend the life of the transmission.

10. How can CARDIAGTECH.NET help with my transmission diagnostic needs?

CARDIAGTECH.NET offers high-quality diagnostic tools, expert support, and comprehensive training to help you accurately diagnose and repair transmission issues, enhance your efficiency, and increase customer satisfaction. Contact us today at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET for expert advice and solutions tailored to your needs.