Explain the Term “Actuator”: A Comprehensive Guide

The term “Actuator” refers to a component that converts energy into mechanical motion, playing a crucial role in automation systems. Let’s explore actuators in detail, from their fundamental principles to their diverse applications, especially in the automotive repair industry, all while keeping in mind how CARDIAGTECH.NET can equip you with the best tools for the job.

1. What is an Actuator?

An actuator is a device that transforms energy, such as electrical, pneumatic, or hydraulic power, into mechanical motion. This motion can be linear, rotary, or oscillatory, depending on the actuator’s design. Actuators are essential in systems that require controlled movement or force application.

To elaborate, actuators are the muscles of any mechanical system. They are responsible for executing commands and performing the physical work required by a control system. Without actuators, automated processes would be impossible. Think of them as the bridge between the electronic control signals and the physical action needed in various applications.

2. What are the Key Types of Actuators?

Actuators are categorized based on their energy source and the type of motion they produce. Here are the main types:

-

Electrical Actuators: These use electrical energy to produce motion, with subtypes including:

- Solenoid Actuators: These actuators use an electromagnetic coil and a movable plunger. When electricity flows through the coil, it creates a magnetic field, pulling the plunger into the coil and producing linear motion. Solenoid actuators are often used for quick, on-off actions in applications such as valves and latches.

- Electric Motors: Electric motors are very versatile. They convert electrical energy into rotary motion. They’re used in many applications and can vary in size and power, from small motors that power toys to big industrial motors. You can control them accurately by using methods like pulse width modulation (PWM).

- Piezoelectric Actuators: These actuators use piezoelectric materials that change shape when an electric field is applied. They offer high precision and fast response times, making them suitable for applications like micropositioning and precision valves.

-

Hydraulic Actuators: These actuators use pressurized hydraulic fluid to generate motion. They are known for their high force and load-carrying capabilities, making them suitable for heavy-duty applications.

-

Pneumatic Actuators: Pneumatic actuators use compressed air to generate motion. They are commonly used in applications where speed and quick response times are important.

-

Thermal Actuators: These actuators use heat to produce motion. They are often used in temperature-sensitive applications.

3. How do Electrical Actuators Work?

Electrical actuators convert electrical energy into mechanical motion through various mechanisms. Here’s a more detailed look:

3.1. Solenoid Actuators

Solenoid actuators operate based on electromagnetism. They consist of a coil of wire and a movable plunger. When an electric current passes through the coil, a magnetic field is created, which pulls the plunger into the coil. This linear motion can be used to activate a switch, open a valve, or perform other mechanical actions.

3.2. Electric Motors

Electric motors come in various types, including DC motors, AC motors, servo motors, and stepper motors.

- DC Motors: DC motors are simple and widely used. They operate by passing a direct current through a coil in a magnetic field, causing the coil to rotate. The speed and direction of the motor can be controlled by varying the voltage and polarity of the current.

- AC Motors: AC motors use alternating current to produce motion. They are commonly used in applications where constant speed is required, such as in fans and pumps.

- Servo Motors: Servo motors are designed for precise control of position and speed. They incorporate a feedback mechanism that allows the motor to adjust its position based on a control signal. Servo motors are used in robotics, CNC machines, and other applications requiring high precision.

- Stepper Motors: Stepper motors move in discrete steps, making them ideal for applications requiring precise positioning. They are commonly used in printers, scanners, and other devices where accurate motion control is essential.

3.3. Piezoelectric Actuators

Piezoelectric actuators utilize the piezoelectric effect, where certain materials change shape when an electric field is applied. These actuators offer very high precision and fast response times, making them suitable for applications such as micropositioning systems, precision valves, and high-frequency transducers.

4. How do Hydraulic Actuators Work?

Hydraulic actuators use the power of pressurized fluid to generate motion. Here’s a detailed breakdown:

4.1. Components of Hydraulic Actuators

A hydraulic actuator system typically includes:

- Hydraulic Cylinder: This is the main component that converts hydraulic pressure into linear motion. It consists of a piston inside a cylinder, with pressurized fluid acting on one side of the piston to move it.

- Hydraulic Pump: The pump is responsible for generating the pressurized hydraulic fluid. It draws fluid from a reservoir and delivers it to the cylinder.

- Control Valves: These valves control the flow of hydraulic fluid to and from the cylinder, allowing precise control of the actuator’s motion.

- Reservoir: The reservoir stores the hydraulic fluid and provides a supply for the pump.

4.2. Working Principle

The hydraulic pump generates pressurized fluid, which is then directed to the hydraulic cylinder through control valves. The pressurized fluid acts on the piston inside the cylinder, causing it to move. By controlling the flow of fluid, the speed, direction, and force of the actuator can be precisely controlled.

4.3. Applications

Hydraulic actuators are used in heavy-duty applications where high force and load-carrying capabilities are required. Common applications include:

- Construction Equipment: Excavators, bulldozers, and other construction machines use hydraulic actuators for lifting, digging, and moving heavy materials.

- Industrial Machinery: Hydraulic actuators are used in presses, forging machines, and other industrial equipment requiring high force.

- Aerospace: Hydraulic actuators are used in aircraft landing gear, flight control surfaces, and other critical systems.

5. How do Pneumatic Actuators Work?

Pneumatic actuators use compressed air to generate motion. Here’s how they function:

5.1. Components of Pneumatic Actuators

A pneumatic actuator system typically consists of:

- Pneumatic Cylinder: This component converts the energy of compressed air into linear motion. Similar to hydraulic cylinders, it includes a piston inside a cylinder.

- Air Compressor: The air compressor generates compressed air, which is the power source for the actuator.

- Control Valves: These valves regulate the flow of compressed air to and from the cylinder, allowing control of the actuator’s motion.

- Air Reservoir: The air reservoir stores compressed air, providing a steady supply for the actuator.

5.2. Working Principle

The air compressor generates compressed air, which is stored in the air reservoir. When the actuator is activated, control valves direct the compressed air to the pneumatic cylinder. The air pressure acts on the piston, causing it to move. By controlling the air flow, the speed, direction, and force of the actuator can be precisely managed.

5.3. Applications

Pneumatic actuators are widely used in applications where speed and quick response times are important. Common applications include:

- Automation Systems: Pneumatic actuators are used in automated assembly lines, packaging machines, and other automated systems.

- Robotics: Pneumatic actuators are used in robotic arms and other robotic systems requiring fast and precise movements.

- Automotive Industry: Pneumatic actuators are used in braking systems, suspension systems, and other automotive applications.

6. What are the Key Parameters to Consider When Selecting an Actuator?

Choosing the right actuator for a specific application requires careful consideration of several key parameters:

- Force or Torque: Determine the amount of force or torque required to perform the desired action. This is crucial for selecting an actuator that can handle the load.

- Stroke Length or Rotation Angle: Define the distance or angle the actuator needs to move. This ensures the actuator can achieve the required range of motion.

- Speed: Consider the required speed of the actuator. Some applications require fast movements, while others can tolerate slower speeds.

- Precision: Evaluate the required level of precision. Applications requiring high accuracy will need actuators with precise control capabilities.

- Operating Environment: Take into account the environmental conditions, such as temperature, humidity, and exposure to chemicals or dust. This will help select an actuator that can withstand the operating environment.

- Duty Cycle: Determine how often the actuator will be used. High-duty cycle applications require actuators designed for continuous operation.

- Power Source: Choose an actuator that is compatible with the available power source, whether it’s electrical, hydraulic, or pneumatic.

- Size and Weight: Consider the size and weight constraints of the application. Smaller and lighter actuators may be necessary for certain applications.

- Cost: Evaluate the cost of the actuator, including initial purchase price and ongoing maintenance costs.

7. What are the Benefits of Using Actuators in Automotive Repair?

Actuators offer numerous benefits in automotive repair, enhancing efficiency, precision, and safety:

- Increased Efficiency: Actuators automate many tasks, reducing the time and effort required for repairs.

- Improved Precision: Actuators provide precise control over movements, ensuring accurate adjustments and alignments.

- Enhanced Safety: Actuators can perform tasks that are dangerous or difficult for humans, improving workplace safety.

- Reduced Labor Costs: By automating tasks, actuators can reduce the need for manual labor, lowering overall repair costs.

- Consistent Performance: Actuators provide consistent and repeatable performance, ensuring high-quality repairs.

8. Where are Actuators Typically Used in Automotive Systems?

Actuators are used in various systems within a vehicle to control different functions:

- Electronic Throttle Control (ETC): Actuators control the throttle valve, regulating the amount of air entering the engine.

- Cruise Control: Actuators maintain a constant vehicle speed by adjusting the throttle.

- Anti-Lock Braking System (ABS): Actuators control the brake pressure to prevent wheel lockup during braking.

- Electronic Stability Control (ESC): Actuators apply individual brakes to help stabilize the vehicle during skidding.

- Automatic Transmission: Actuators control the shifting of gears in automatic transmissions.

- Power Windows and Door Locks: Actuators control the movement of power windows and the locking/unlocking of doors.

- Adjustable Seats: Actuators adjust the position of the seats for optimal comfort.

- Active Suspension Systems: Actuators control the suspension components to improve ride quality and handling.

- Variable Valve Timing (VVT): Actuators adjust the timing of the intake and exhaust valves to optimize engine performance.

9. What are Some Common Problems with Actuators in Automotive Applications?

Like any mechanical component, actuators can experience problems over time. Common issues include:

- Wear and Tear: Actuators are subject to wear and tear due to continuous operation, leading to reduced performance or failure.

- Contamination: Exposure to dirt, moisture, and other contaminants can damage actuators and cause them to malfunction.

- Electrical Issues: Electrical problems, such as short circuits, open circuits, or faulty wiring, can prevent actuators from operating correctly.

- Mechanical Damage: Physical damage, such as broken gears or bent components, can render actuators inoperable.

- Fluid Leaks: In hydraulic and pneumatic actuators, fluid leaks can reduce performance and cause the actuator to fail.

- Corrosion: Corrosion can damage actuator components, especially in harsh environments.

- Overloading: Exceeding the actuator’s load capacity can cause it to fail prematurely.

10. How Do You Diagnose Actuator Problems?

Diagnosing actuator problems involves a systematic approach to identify the root cause of the issue:

- Visual Inspection: Start by visually inspecting the actuator for any signs of damage, such as cracks, leaks, or broken components.

- Electrical Testing: Use a multimeter to check the actuator’s electrical connections, voltage, and current.

- Functional Testing: Perform functional tests to see if the actuator is operating correctly. This may involve using a scan tool to activate the actuator and observe its response.

- Pressure Testing: For hydraulic and pneumatic actuators, check the pressure levels to ensure they are within the specified range.

- Component Testing: Test individual components of the actuator, such as the motor, solenoid, or valve, to identify any faults.

- Diagnostic Codes: Use a scan tool to retrieve diagnostic trouble codes (DTCs) related to the actuator. These codes can provide valuable information about the nature of the problem.

11. How to Maintain Actuators to Ensure Longevity

Proper maintenance is essential to ensure the longevity and reliable performance of actuators. Here are some key maintenance practices:

- Regular Inspection: Regularly inspect actuators for any signs of wear, damage, or leaks.

- Lubrication: Lubricate moving parts to reduce friction and wear. Use the manufacturer-recommended lubricant.

- Cleaning: Keep actuators clean and free from dirt, dust, and other contaminants.

- Tightening Connections: Ensure all electrical and mechanical connections are tight and secure.

- Filter Replacement: Replace filters in hydraulic and pneumatic systems to prevent contamination.

- Fluid Level Checks: Regularly check the fluid levels in hydraulic systems and top up as needed.

- Pressure Testing: Periodically test the pressure levels in hydraulic and pneumatic systems to ensure they are within the specified range.

- Component Replacement: Replace worn or damaged components promptly to prevent further damage.

12. What is the Role of Actuators in Modern Automotive Technology?

Actuators are critical components in modern automotive technology, enabling advanced features and enhancing vehicle performance, safety, and efficiency:

- Advanced Driver Assistance Systems (ADAS): Actuators are used in ADAS features such as adaptive cruise control, lane keeping assist, and automatic emergency braking.

- Autonomous Driving: Actuators play a key role in autonomous vehicles, controlling steering, throttle, and braking.

- Electric Vehicles (EVs): Actuators are used in EVs for various functions, including battery management, thermal management, and regenerative braking.

- Hybrid Vehicles: Actuators are used in hybrid vehicles to manage the transition between electric and gasoline power.

- Fuel Efficiency: Actuators help optimize engine performance and reduce fuel consumption through precise control of various systems.

- Emissions Control: Actuators play a role in reducing emissions by controlling the exhaust gas recirculation (EGR) system and other emissions control devices.

13. What are the Future Trends in Actuator Technology?

Actuator technology is continuously evolving, with several trends shaping its future:

- Miniaturization: There is a growing trend towards smaller and more compact actuators, enabling their use in a wider range of applications.

- Smart Actuators: Smart actuators incorporate sensors, microprocessors, and communication interfaces, allowing them to be integrated into intelligent control systems.

- Energy Efficiency: There is a focus on developing more energy-efficient actuators to reduce energy consumption and operating costs.

- Advanced Materials: New materials, such as shape memory alloys and electroactive polymers, are being used to create actuators with improved performance and durability.

- Wireless Control: Wireless control of actuators is becoming more common, allowing for greater flexibility and ease of integration.

- Increased Integration: Actuators are being increasingly integrated into larger systems, such as robotic arms and automated assembly lines, to improve overall performance and efficiency.

14. How Does CARDIAGTECH.NET Support Automotive Technicians in Actuator-Related Tasks?

CARDIAGTECH.NET offers a range of tools and equipment to support automotive technicians in diagnosing, repairing, and maintaining actuators:

- Scan Tools: Advanced scan tools capable of reading and interpreting diagnostic trouble codes (DTCs) related to actuators, providing valuable insights into potential issues.

- Multimeters: High-quality multimeters for performing electrical tests on actuators, checking voltage, current, and resistance.

- Pressure Testers: Pressure testers for hydraulic and pneumatic systems, allowing technicians to verify that pressure levels are within the specified range.

- Specialized Tools: Specialized tools for removing and installing actuators, ensuring the job is done correctly and efficiently.

- Diagnostic Software: Access to comprehensive diagnostic software that provides detailed information about actuator operation and troubleshooting procedures.

By providing these tools and resources, CARDIAGTECH.NET empowers automotive technicians to tackle actuator-related tasks with confidence and efficiency, leading to improved repair quality and customer satisfaction.

15. Why Choose CARDIAGTECH.NET for Your Automotive Tool Needs?

Choosing CARDIAGTECH.NET for your automotive tool needs offers several advantages:

- Quality Products: CARDIAGTECH.NET offers a wide range of high-quality tools and equipment from leading manufacturers, ensuring reliable performance and durability.

- Competitive Prices: CARDIAGTECH.NET provides competitive prices on all products, helping you save money without compromising on quality.

- Expert Support: CARDIAGTECH.NET offers expert technical support to help you choose the right tools for your needs and troubleshoot any issues you may encounter.

- Convenient Online Shopping: CARDIAGTECH.NET provides a convenient online shopping experience, allowing you to browse and purchase tools from the comfort of your own home or shop.

- Fast Shipping: CARDIAGTECH.NET offers fast and reliable shipping, ensuring you receive your tools quickly and efficiently.

- Customer Satisfaction: CARDIAGTECH.NET is committed to customer satisfaction, offering a hassle-free return policy and responsive customer service.

16. Actuators in Electric Vehicles (EVs)

Electric vehicles (EVs) rely heavily on actuators for a variety of functions. Here are some key applications:

- Battery Management Systems (BMS): Actuators control cooling systems to maintain optimal battery temperature, which is crucial for battery life and performance.

- Thermal Management: Actuators manage the flow of coolant to regulate the temperature of the motor, inverter, and other critical components.

- Regenerative Braking: Actuators control the regenerative braking system, which recovers energy during deceleration and stores it back in the battery.

- Electronic Power Steering (EPS): Actuators provide power assist to the steering system, making it easier to steer the vehicle.

- Active Suspension Systems: Actuators adjust the suspension components to improve ride quality and handling.

17. Actuators in Hybrid Vehicles

Hybrid vehicles use a combination of electric and gasoline power, and actuators play a crucial role in managing the transition between these power sources:

- Power Split Device: Actuators control the power split device, which determines how much power is delivered by the electric motor and the gasoline engine.

- Regenerative Braking: Actuators manage the regenerative braking system, capturing energy during deceleration and storing it in the battery.

- Engine Start/Stop System: Actuators control the engine start/stop system, which automatically shuts off the engine when the vehicle is stopped to save fuel.

- Thermal Management: Actuators regulate the temperature of the battery, electric motor, and gasoline engine to ensure optimal performance.

18. The Integration of Sensors and Actuators

The integration of sensors and actuators is essential for creating intelligent control systems. Sensors provide feedback on the system’s performance, while actuators execute the control actions:

- Closed-Loop Control: Sensors and actuators work together in closed-loop control systems, where the sensor provides feedback to the controller, which then adjusts the actuator to maintain the desired output.

- Adaptive Control: Sensors and actuators enable adaptive control systems, which can automatically adjust their behavior based on changing conditions.

- Predictive Maintenance: Sensors can monitor the performance of actuators and detect early signs of wear or failure, allowing for predictive maintenance.

- Remote Monitoring: Sensors and actuators can be remotely monitored and controlled, enabling remote diagnostics and troubleshooting.

19. Challenges in Actuator Technology

Despite the numerous benefits of actuators, there are several challenges that need to be addressed:

- Reliability: Improving the reliability of actuators is essential for ensuring the safe and reliable operation of vehicles and other systems.

- Cost: Reducing the cost of actuators is important for making them more accessible to a wider range of applications.

- Energy Efficiency: Improving the energy efficiency of actuators is crucial for reducing energy consumption and operating costs.

- Size and Weight: Reducing the size and weight of actuators is important for applications where space and weight are limited.

- Environmental Impact: Minimizing the environmental impact of actuators is essential for creating sustainable technologies.

20. Emerging Technologies in Actuator Development

Several emerging technologies are driving advancements in actuator development:

- Micro-Electro-Mechanical Systems (MEMS): MEMS technology enables the creation of very small actuators with high precision and fast response times.

- Shape Memory Alloys (SMAs): SMAs are materials that can change shape in response to temperature changes, making them suitable for use in actuators.

- Electroactive Polymers (EAPs): EAPs are materials that can change shape in response to an electric field, offering potential for creating flexible and lightweight actuators.

- Artificial Muscles: Artificial muscles are actuators that mimic the behavior of biological muscles, providing high force and flexibility.

- 3D Printing: 3D printing is being used to create custom actuators with complex geometries and optimized performance.

21. The Importance of Actuator Testing and Validation

Thorough testing and validation of actuators are essential for ensuring their reliable performance and safety:

- Performance Testing: Performance testing involves measuring the actuator’s force, speed, precision, and other key parameters.

- Environmental Testing: Environmental testing involves subjecting the actuator to extreme temperatures, humidity, vibration, and other environmental conditions to assess its durability.

- Life Cycle Testing: Life cycle testing involves operating the actuator for an extended period of time to assess its long-term reliability.

- Safety Testing: Safety testing involves evaluating the actuator’s safety features and ensuring that it meets all applicable safety standards.

22. Actuators in Robotics and Automation

Actuators are fundamental components in robotics and automation systems, enabling robots and automated machines to perform a wide range of tasks:

- Robotic Arms: Actuators control the joints of robotic arms, allowing them to move and manipulate objects.

- Automated Assembly Lines: Actuators are used in automated assembly lines to perform tasks such as picking, placing, and fastening components.

- CNC Machines: Actuators control the movement of cutting tools in CNC machines, enabling precise machining operations.

- Packaging Machines: Actuators are used in packaging machines to fill, seal, and label products.

23. Actuators in Aerospace Applications

Actuators are critical components in aerospace applications, controlling various systems in aircraft and spacecraft:

- Flight Control Surfaces: Actuators control the ailerons, elevators, and rudder of aircraft, allowing pilots to control the aircraft’s attitude and direction.

- Landing Gear: Actuators deploy and retract the landing gear of aircraft.

- Engine Control: Actuators control the fuel flow, air intake, and other parameters of aircraft engines.

- Spacecraft Propulsion: Actuators control the thrusters of spacecraft, enabling them to maneuver in space.

24. How to Choose the Right Actuator for Your Automotive Repair Needs

Choosing the right actuator for your automotive repair needs involves considering several factors:

- Application: Determine the specific application for which the actuator will be used.

- Force and Stroke: Determine the required force and stroke length.

- Speed and Precision: Consider the required speed and precision.

- Operating Environment: Take into account the operating environment.

- Power Source: Choose an actuator that is compatible with the available power source.

- Size and Weight: Consider the size and weight constraints.

- Cost: Evaluate the cost of the actuator.

- Reliability: Choose an actuator from a reputable manufacturer with a proven track record of reliability.

25. Case Studies of Actuator Applications in Automotive Repair

To illustrate the practical applications of actuators in automotive repair, here are a few case studies:

- Electronic Throttle Control (ETC) Repair: An automotive technician uses a scan tool to diagnose a faulty throttle actuator in a vehicle with ETC. The technician replaces the actuator and calibrates it using the scan tool, restoring the vehicle’s throttle control.

- Anti-Lock Braking System (ABS) Repair: An automotive technician uses a pressure tester to diagnose a faulty ABS actuator in a vehicle with ABS. The technician replaces the actuator and bleeds the brake system, restoring the vehicle’s ABS function.

- Variable Valve Timing (VVT) Repair: An automotive technician uses a diagnostic scope to diagnose a faulty VVT actuator in a vehicle with VVT. The technician replaces the actuator and adjusts the valve timing, restoring the vehicle’s engine performance.

26. The Role of Actuators in Vehicle Safety Systems

Actuators play a vital role in vehicle safety systems, helping to prevent accidents and protect occupants in the event of a collision:

- Anti-Lock Braking System (ABS): Actuators control the brake pressure to prevent wheel lockup during braking, allowing the driver to maintain steering control.

- Electronic Stability Control (ESC): Actuators apply individual brakes to help stabilize the vehicle during skidding, preventing loss of control.

- Adaptive Cruise Control (ACC): Actuators adjust the throttle and brakes to maintain a safe following distance from the vehicle ahead, reducing the risk of rear-end collisions.

- Automatic Emergency Braking (AEB): Actuators automatically apply the brakes to avoid or mitigate collisions, reducing the severity of accidents.

- Airbag Deployment: Actuators trigger the deployment of airbags in the event of a collision, protecting occupants from injury.

27. Actuators and Fuel Efficiency

Actuators contribute significantly to improving vehicle fuel efficiency:

- Electronic Throttle Control (ETC): ETC systems use actuators to precisely control the amount of air entering the engine, optimizing combustion and reducing fuel consumption.

- Variable Valve Timing (VVT): VVT systems use actuators to adjust the timing of the intake and exhaust valves, optimizing engine performance and reducing fuel consumption.

- Cylinder Deactivation: Cylinder deactivation systems use actuators to shut off some of the engine’s cylinders under light load conditions, reducing fuel consumption.

- Start-Stop Systems: Start-stop systems use actuators to automatically shut off the engine when the vehicle is stopped, saving fuel and reducing emissions.

28. How Actuators Contribute to a Smoother Driving Experience

Actuators enhance the overall driving experience by providing smoother and more responsive control:

- Electronic Power Steering (EPS): EPS systems use actuators to provide power assist to the steering system, making it easier to steer the vehicle and providing a more comfortable driving experience.

- Active Suspension Systems: Active suspension systems use actuators to adjust the suspension components in real-time, improving ride quality and handling.

- Automatic Transmissions: Automatic transmissions use actuators to smoothly shift gears, providing a seamless and comfortable driving experience.

- Adaptive Cruise Control (ACC): ACC systems use actuators to maintain a safe following distance from the vehicle ahead, reducing driver fatigue and improving the overall driving experience.

29. Actuators and Vehicle Emissions Control

Actuators play a crucial role in controlling vehicle emissions and reducing air pollution:

- Exhaust Gas Recirculation (EGR): EGR systems use actuators to recirculate a portion of the exhaust gas back into the engine, reducing nitrogen oxide (NOx) emissions.

- Selective Catalytic Reduction (SCR): SCR systems use actuators to inject a urea solution into the exhaust gas, converting NOx into harmless nitrogen and water.

- Diesel Particulate Filter (DPF): DPF systems use actuators to control the regeneration process, burning off accumulated soot and reducing particulate matter emissions.

- Three-Way Catalytic Converter (TWC): TWC systems use actuators to optimize the air-fuel ratio, converting hydrocarbons (HC), carbon monoxide (CO), and NOx into less harmful substances.

30. Get Your Actuator Tools and Equipment from CARDIAGTECH.NET Today

In conclusion, actuators are indispensable components in modern automotive systems, enabling advanced features, enhancing vehicle performance, and improving safety. Understanding the principles, types, applications, and maintenance of actuators is essential for automotive technicians. With the right tools and equipment from CARDIAGTECH.NET, you can confidently tackle actuator-related tasks, ensuring high-quality repairs and customer satisfaction.

Don’t let outdated tools hold you back. Upgrade your toolkit with the best from CARDIAGTECH.NET and experience the difference in efficiency and precision.

Ready to elevate your automotive repair capabilities? Contact CARDIAGTECH.NET today for expert advice on the best actuator tools and equipment for your needs. Call us at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let us help you enhance your efficiency, precision, and safety in every repair job.

Automotive Actuators

Automotive Actuators

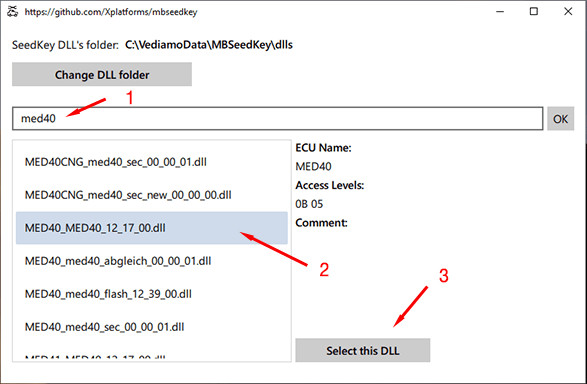

The image displays a graph illustrating the relationship between force, speed, durability, and energy efficiency in automotive actuators, emphasizing the trade-offs and considerations in selecting the right actuator for specific applications.

Frequently Asked Questions (FAQ) About Actuators

1. What is the primary function of an actuator?

The primary function of an actuator is to convert energy (electrical, pneumatic, or hydraulic) into mechanical motion, facilitating movement or force application in a system.

2. What are the main types of actuators used in automotive applications?

The main types include electrical (solenoid, motor, piezoelectric), hydraulic, and pneumatic actuators, each suited for different tasks based on force, speed, and precision requirements.

3. How do electrical actuators work in vehicles?

Electrical actuators use electromagnetic forces or electric fields to create motion. For example, a solenoid actuator uses a magnetic field to pull a plunger, while an electric motor converts electrical energy into rotary motion.

4. What common problems can occur with actuators in automotive systems?

Common issues include wear and tear, contamination, electrical faults, mechanical damage, fluid leaks (in hydraulic/pneumatic types), corrosion, and overloading, all impacting performance.

5. How can you diagnose actuator problems effectively?

Effective diagnosis involves visual inspections, electrical testing (multimeter), functional testing (scan tool), pressure testing (hydraulic/pneumatic), component testing, and interpreting diagnostic trouble codes (DTCs).

6. What maintenance practices can extend the life of automotive actuators?

Regular maintenance includes frequent inspections, lubrication of moving parts, cleaning to remove contaminants, tightening connections, replacing filters, checking fluid levels, and promptly replacing worn components.

7. In what vehicle systems are actuators most commonly found?

Actuators are found in electronic throttle control (ETC), cruise control, anti-lock braking systems (ABS), electronic stability control (ESC), automatic transmissions, power windows/locks, and adjustable seats.

8. What role do actuators play in electric and hybrid vehicles?

In EVs and hybrids, actuators are critical for battery and thermal management, regenerative braking, electronic power steering, and managing the transition between power sources, enhancing efficiency and performance.

9. How does CARDIAGTECH.NET support automotive technicians working with actuators?

CARDIAGTECH.NET provides scan tools for DTC reading, multimeters for electrical testing, pressure testers for hydraulic systems, specialized tools for actuator replacement, and comprehensive diagnostic software to aid in accurate repairs.

10. What future trends are expected in actuator technology?

Future trends include miniaturization, smart actuators with integrated sensors, increased energy efficiency, use of advanced materials (shape memory alloys, electroactive polymers), wireless control, and tighter integration into larger systems.