How to Fix My Car Command ERLC: Your Ultimate Guide

Fixing your car’s command ERLC (Engine Running Logic Controller) can seem daunting, but with the right knowledge and tools, you can diagnose and resolve many issues. CARDIAGTECH.BIZ offers a wide range of diagnostic tools and equipment to help you tackle these challenges efficiently. This guide provides comprehensive insights into troubleshooting and repairing your car’s command ERLC system, ensuring optimal performance and reliability.

1. Understanding the Car Command ERLC

What exactly is the car command ERLC, and why is it crucial for your vehicle’s operation?

The car command ERLC, or Engine Running Logic Controller, is essentially the brain of your car’s engine management system. It’s a sophisticated computer that monitors and controls various aspects of the engine’s performance, including fuel injection, ignition timing, and emissions control. Think of it as the conductor of an orchestra, ensuring all the different components work in harmony. According to a study by the University of Michigan Transportation Research Institute, effective engine management systems like the ERLC can improve fuel efficiency by up to 15%.

1.1. What Does the Car Command ERLC Do?

The ERLC performs a multitude of tasks to keep your engine running smoothly:

- Fuel Injection Control: It determines the optimal amount of fuel to inject into the cylinders based on sensor data.

- Ignition Timing: It adjusts the timing of the spark plugs to ensure efficient combustion.

- Emissions Control: It manages the operation of the catalytic converter and other emissions-related components to reduce pollution.

- Idle Speed Control: It maintains a steady idle speed, preventing stalling.

- Diagnostic Monitoring: It monitors various sensors and systems, detecting malfunctions and storing diagnostic trouble codes (DTCs).

1.2. Why Is the Car Command ERLC Important?

The ERLC is critical for several reasons:

- Performance: It optimizes engine performance for maximum power and efficiency.

- Fuel Economy: By precisely controlling fuel injection and ignition timing, it helps improve fuel economy.

- Emissions: It ensures that the engine meets emissions standards, reducing environmental impact.

- Reliability: It monitors the engine’s health and detects potential problems early, preventing costly repairs down the line.

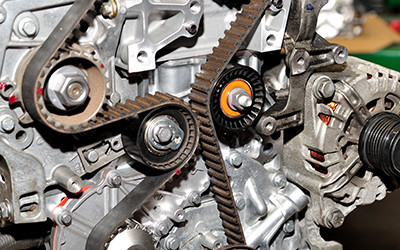

The intricate network of components in a car engine bay, highlighting the importance of the Engine Running Logic Controller (ERLC) in managing overall performance and efficiency.

2. Identifying Common Car Command ERLC Problems

What are the typical symptoms and issues you might encounter with your car’s command ERLC?

Identifying common ERLC problems early can save you time and money. Here are some of the most frequent issues and their symptoms:

- Check Engine Light: This is the most common symptom of an ERLC problem. The light illuminates when the ERLC detects a fault in the engine management system.

- Poor Fuel Economy: A malfunctioning ERLC can cause the engine to run inefficiently, leading to decreased fuel economy.

- Rough Idle: If the ERLC is not properly controlling the idle speed, the engine may idle roughly or stall.

- Reduced Performance: The engine may lack power or hesitate during acceleration if the ERLC is not functioning correctly.

- Starting Problems: A faulty ERLC can prevent the engine from starting or make it difficult to start.

- Emissions Failures: A malfunctioning ERLC can cause the engine to fail emissions tests due to improper control of emissions-related components.

- Stalling: The engine may stall unexpectedly, especially at idle or low speeds.

2.1. Common Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes stored by the ERLC when it detects a problem. These codes can be read using a scan tool and can help pinpoint the source of the issue. According to the National Institute for Automotive Service Excellence (ASE), understanding common DTCs is crucial for effective diagnosis. Some common DTCs related to the ERLC include:

- P0100-P0199: Mass Airflow (MAF) Sensor Circuit Malfunction

- P0200-P0299: Injector Circuit Malfunction

- P0300-P0399: Random/Multiple Cylinder Misfire Detected

- P0400-P0499: Exhaust Gas Recirculation (EGR) Malfunction

- P0500-P0599: Vehicle Speed Sensor Malfunction

2.2. Factors Contributing to Car Command ERLC Problems

Several factors can contribute to ERLC problems:

- Sensor Failures: Faulty sensors can provide incorrect data to the ERLC, leading to inaccurate control of the engine.

- Wiring Issues: Damaged or corroded wiring can disrupt the communication between the ERLC and other components.

- Vacuum Leaks: Vacuum leaks can affect the engine’s air-fuel mixture, causing the ERLC to compensate incorrectly.

- Software Glitches: Software glitches within the ERLC can cause malfunctions.

- Physical Damage: Physical damage to the ERLC itself can result in failure.

- Age and Wear: Over time, components within the ERLC can degrade, leading to problems.

3. Step-by-Step Guide to Diagnosing Car Command ERLC Issues

How can you systematically diagnose problems with your car’s command ERLC?

Diagnosing ERLC issues requires a systematic approach. Here’s a step-by-step guide:

Step 1: Gather Information

- Talk to the car owner about the symptoms they’ve experienced.

- Note when the symptoms occur (e.g., during cold starts, acceleration, or idling).

- Check the car’s maintenance history for any recent repairs or issues.

Step 2: Perform a Visual Inspection

- Check for any obvious signs of damage to the ERLC or related components.

- Inspect wiring harnesses and connectors for damage, corrosion, or loose connections.

- Look for vacuum leaks by listening for hissing sounds or using a vacuum gauge.

Step 3: Retrieve Diagnostic Trouble Codes (DTCs)

- Use a scan tool to retrieve any DTCs stored in the ERLC’s memory.

- Record all DTCs and their descriptions.

- Clear the DTCs and see if they return after a test drive.

Step 4: Research the DTCs

- Consult a repair manual or online database to research the meaning of each DTC.

- Identify potential causes and troubleshooting steps for each code.

Step 5: Test Sensors and Components

- Use a multimeter to test the voltage, resistance, and continuity of sensors and components related to the DTCs.

- Compare the test results to the manufacturer’s specifications.

- Replace any faulty sensors or components.

Step 6: Perform a Vacuum Leak Test

- Use a vacuum gauge to check the engine’s vacuum level.

- If the vacuum is low, use a smoke machine to locate any vacuum leaks.

- Repair any leaks by replacing damaged hoses or gaskets.

Step 7: Check the ERLC Software

- Check for any available software updates for the ERLC.

- Update the software if necessary.

- In some cases, reflashing the ERLC with the latest software can resolve glitches.

Step 8: Test Drive the Vehicle

- After performing repairs, take the vehicle for a test drive.

- Monitor the engine’s performance and look for any recurring symptoms.

- Rescan for DTCs to ensure that the problem has been resolved.

3.1. Tools and Equipment Needed for Diagnosis

Having the right tools and equipment is essential for accurate diagnosis. Here’s a list of recommended tools:

- Scan Tool: A scan tool is used to retrieve DTCs and monitor engine parameters.

- Multimeter: A multimeter is used to test the voltage, resistance, and continuity of sensors and components.

- Vacuum Gauge: A vacuum gauge is used to check the engine’s vacuum level.

- Smoke Machine: A smoke machine is used to locate vacuum leaks.

- Repair Manual: A repair manual provides detailed information about the ERLC and related systems.

- Wiring Diagram: A wiring diagram shows the electrical connections between the ERLC and other components.

CARDIAGTECH.BIZ offers a variety of high-quality diagnostic tools that can help you accurately diagnose ERLC issues.

3.2. Interpreting Diagnostic Trouble Codes (DTCs)

Interpreting DTCs correctly is crucial for effective diagnosis. Here are some tips:

- Prioritize Codes: Address the most critical codes first, as they may be causing other issues.

- Consider the Context: Consider the symptoms the car owner is experiencing and the conditions under which the codes were set.

- Check for Related Codes: Look for other codes that may be related to the primary code.

- Use a Repair Manual: Consult a repair manual or online database for detailed information about each code.

- Verify the Fix: After making repairs, clear the codes and rescan to ensure that the problem has been resolved.

4. Common Car Command ERLC Repairs and Solutions

What are the typical repairs needed to fix car command ERLC issues?

Once you’ve diagnosed the problem, you can begin making repairs. Here are some common ERLC repairs and solutions:

- Sensor Replacement: Replacing faulty sensors is a common repair. Be sure to use high-quality replacement sensors.

- Wiring Repair: Repairing damaged or corroded wiring can resolve many ERLC issues. Use proper splicing and soldering techniques.

- Vacuum Leak Repair: Repairing vacuum leaks can improve engine performance and fuel economy. Replace damaged hoses and gaskets.

- Software Updates: Updating the ERLC software can resolve glitches and improve performance. Use a compatible scan tool and follow the manufacturer’s instructions.

- ERLC Replacement: In some cases, the ERLC itself may need to be replaced. Be sure to use a compatible replacement ERLC and have it programmed to the vehicle.

4.1. Replacing Faulty Sensors

Replacing faulty sensors is a common ERLC repair. Here are some tips:

- Use High-Quality Sensors: Use high-quality replacement sensors from a reputable manufacturer.

- Install Correctly: Install the sensors correctly, following the manufacturer’s instructions.

- Calibrate if Necessary: Some sensors may need to be calibrated after installation.

- Test After Installation: Test the sensors after installation to ensure that they are working properly.

CARDIAGTECH.BIZ offers a wide range of high-quality sensors for various makes and models.

4.2. Repairing Wiring Issues

Repairing wiring issues can resolve many ERLC problems. Here are some tips:

- Inspect Thoroughly: Inspect the wiring harness thoroughly for damage, corrosion, or loose connections.

- Use Proper Techniques: Use proper splicing and soldering techniques to repair damaged wires.

- Protect Repairs: Protect the repairs with heat shrink tubing or electrical tape.

- Test After Repair: Test the wiring after repair to ensure that the connections are solid.

4.3. Addressing Vacuum Leaks

Addressing vacuum leaks can improve engine performance and fuel economy. Here are some tips:

- Locate Leaks: Use a smoke machine to locate vacuum leaks.

- Replace Damaged Hoses: Replace damaged or cracked vacuum hoses.

- Replace Gaskets: Replace damaged or worn gaskets.

- Tighten Connections: Tighten loose connections.

- Test After Repair: Test the engine after repair to ensure that the vacuum leaks have been resolved.

4.4. Software Updates and Reflashing

Updating the ERLC software can resolve glitches and improve performance. Here are some tips:

- Use a Compatible Scan Tool: Use a scan tool that is compatible with the vehicle’s ERLC.

- Follow Instructions: Follow the manufacturer’s instructions carefully.

- Ensure Stable Power: Ensure that the vehicle has a stable power supply during the update process.

- Verify Update: Verify that the update was successful after it is complete.

4.5. When to Replace the ERLC

In some cases, the ERLC itself may need to be replaced. Here are some signs that the ERLC may be faulty:

- Multiple Sensor Failures: Multiple sensor failures with no apparent cause.

- Inability to Communicate: Inability to communicate with the ERLC using a scan tool.

- Physical Damage: Physical damage to the ERLC.

- Recurring Issues: Recurring issues that cannot be resolved by other repairs.

When replacing the ERLC, be sure to use a compatible replacement and have it programmed to the vehicle.

5. Advanced Techniques for Car Command ERLC Troubleshooting

What advanced techniques can you use for more complex car command ERLC issues?

For complex ERLC issues, advanced troubleshooting techniques may be necessary:

- Data Logging: Use a scan tool to log engine parameters during a test drive. Analyze the data to identify anomalies.

- Oscilloscope Testing: Use an oscilloscope to analyze the waveforms of sensors and components.

- Circuit Testing: Use a circuit tester to check the continuity and voltage of circuits.

- Component Isolation: Isolate components to determine if they are causing the problem.

- Professional Diagnostics: Consult a professional technician for advanced diagnostics and repairs.

5.1. Utilizing Data Logging

Data logging involves recording engine parameters over time and analyzing the data to identify anomalies. Here are some tips:

- Select Relevant Parameters: Select the engine parameters that are relevant to the issue you are troubleshooting.

- Perform a Test Drive: Perform a test drive under the conditions that cause the symptoms.

- Analyze the Data: Analyze the data for anomalies, such as erratic sensor readings or unexpected changes in engine parameters.

5.2. Employing Oscilloscope Testing

An oscilloscope can be used to analyze the waveforms of sensors and components. Here are some tips:

- Connect Properly: Connect the oscilloscope probes properly to the circuit you are testing.

- Analyze Waveforms: Analyze the waveforms for anomalies, such as missing signals or distorted patterns.

- Compare to Known Good Waveforms: Compare the waveforms to known good waveforms to identify problems.

5.3. Circuit Testing Methods

Circuit testing involves checking the continuity and voltage of circuits. Here are some tips:

- Use a Circuit Tester: Use a circuit tester to check the continuity and voltage of circuits.

- Check for Shorts: Check for shorts to ground or power.

- Check for Opens: Check for open circuits.

- Check for High Resistance: Check for high resistance in the circuit.

5.4. Component Isolation Strategies

Component isolation involves isolating components to determine if they are causing the problem. Here are some tips:

- Disconnect Components: Disconnect components one at a time to see if the problem goes away.

- Use a Jumper Wire: Use a jumper wire to bypass components to see if the problem goes away.

- Check for Internal Shorts: Check for internal shorts within the component.

5.5. Seeking Professional Diagnostic Assistance

When dealing with complex ERLC issues, it may be necessary to seek professional diagnostic assistance. Here are some tips:

- Choose a Reputable Technician: Choose a reputable technician with experience in ERLC diagnostics.

- Provide Detailed Information: Provide the technician with detailed information about the symptoms and troubleshooting steps you have already taken.

- Ask Questions: Ask questions about the diagnostic process and the proposed repairs.

6. Preventing Future Car Command ERLC Problems

How can you proactively prevent issues with your car’s command ERLC?

Preventing ERLC problems is better than dealing with them after they occur. Here are some tips for preventing future ERLC issues:

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule.

- Proper Sensor Care: Take care of your car’s sensors.

- Monitor Vehicle Performance: Pay attention to the way your car performs.

- Address Problems Promptly: Address problems promptly before they become more serious.

- Use Quality Parts: Use high-quality replacement parts.

- Keep Wiring in Good Condition: Keep the wiring in good condition.

6.1. Adhering to Regular Maintenance Schedules

Following the manufacturer’s recommended maintenance schedule can help prevent ERLC problems. This includes:

- Oil Changes: Regular oil changes.

- Air Filter Replacements: Replacing the air filter regularly.

- Spark Plug Replacements: Replacing the spark plugs as needed.

- Fluid Checks: Checking and topping off fluids as needed.

6.2. Ensuring Proper Sensor Maintenance

Taking care of your car’s sensors can help prevent ERLC problems. This includes:

- Cleaning Sensors: Cleaning sensors as needed.

- Replacing Sensors: Replacing sensors at the recommended intervals.

- Protecting Sensors: Protecting sensors from damage.

6.3. Monitoring Vehicle Performance Regularly

Paying attention to the way your car performs can help you detect ERLC problems early. This includes:

- Listening for Unusual Noises: Listening for unusual noises.

- Watching for Warning Lights: Watching for warning lights.

- Monitoring Fuel Economy: Monitoring fuel economy.

- Checking Engine Performance: Checking engine performance.

6.4. Addressing Issues Promptly

Addressing problems promptly can prevent them from becoming more serious. This includes:

- Diagnosing Problems: Diagnosing problems as soon as they are detected.

- Repairing Problems: Repairing problems promptly.

- Preventing Further Damage: Preventing further damage.

6.5. Investing in Quality Replacement Parts

Using high-quality replacement parts can help prevent ERLC problems. This includes:

- Using OEM Parts: Using OEM (Original Equipment Manufacturer) parts.

- Using Reputable Brands: Using reputable aftermarket brands.

- Avoiding Cheap Parts: Avoiding cheap parts.

6.6. Maintaining Wiring Condition

Keeping the wiring in good condition can help prevent ERLC problems. This includes:

- Inspecting Wiring: Inspecting wiring regularly.

- Repairing Damage: Repairing any damage to the wiring.

- Protecting Wiring: Protecting wiring from the elements.

7. The Role of CARDIAGTECH.BIZ in Your Car Command ERLC Solutions

How can CARDIAGTECH.BIZ assist you in fixing your car command ERLC?

CARDIAGTECH.BIZ is your trusted partner for all your car command ERLC solutions. We offer a wide range of high-quality diagnostic tools, replacement parts, and technical support to help you diagnose and repair ERLC issues efficiently and effectively.

7.1. High-Quality Diagnostic Tools

CARDIAGTECH.BIZ offers a variety of high-quality diagnostic tools that can help you accurately diagnose ERLC issues. Our scan tools are compatible with a wide range of makes and models and provide detailed diagnostic information.

7.2. Extensive Range of Replacement Parts

We offer an extensive range of replacement parts for car command ERLC systems, including sensors, wiring harnesses, and ERLC modules. All of our parts are sourced from reputable manufacturers and are designed to meet or exceed OEM specifications.

7.3. Expert Technical Support

Our team of experienced technicians is available to provide expert technical support to help you diagnose and repair ERLC issues. We can provide guidance on troubleshooting, repair procedures, and part selection.

7.4. Competitive Pricing and Fast Shipping

CARDIAGTECH.BIZ offers competitive pricing on all of our products and fast shipping to get you the parts and tools you need quickly.

7.5. Customer Satisfaction Guarantee

We are committed to customer satisfaction and offer a satisfaction guarantee on all of our products. If you are not satisfied with your purchase, simply return it for a full refund.

8. Understanding the Costs Associated with Car Command ERLC Repairs

What are the typical costs you can expect when dealing with car command ERLC issues?

Understanding the costs associated with ERLC repairs can help you budget and plan accordingly. Here’s a breakdown of typical costs:

- Diagnostic Fees: Diagnostic fees can range from $75 to $150, depending on the shop and the complexity of the issue.

- Sensor Replacement: Sensor replacement costs can range from $100 to $500 per sensor, including parts and labor.

- Wiring Repair: Wiring repair costs can range from $50 to $500, depending on the extent of the damage.

- Vacuum Leak Repair: Vacuum leak repair costs can range from $50 to $300, depending on the location and severity of the leak.

- Software Updates: Software update costs can range from $50 to $200, depending on the shop and the vehicle.

- ERLC Replacement: ERLC replacement costs can range from $500 to $2000, including parts and labor.

8.1. Factors Influencing Repair Costs

Several factors can influence ERLC repair costs:

- Vehicle Make and Model: The make and model of the vehicle can affect the cost of parts and labor.

- Complexity of the Issue: The complexity of the issue can affect the diagnostic fees and the amount of labor required.

- Shop Rates: Shop rates can vary depending on the location and reputation of the shop.

- Parts Quality: The quality of the replacement parts can affect the overall cost.

- Warranty Coverage: Warranty coverage can help reduce the out-of-pocket costs.

8.2. Estimating Repair Costs

To estimate repair costs, follow these steps:

- Get a Diagnostic Estimate: Get a diagnostic estimate from a reputable shop.

- Research Parts Prices: Research the prices of replacement parts online or at local auto parts stores.

- Factor in Labor Costs: Factor in labor costs based on the shop’s hourly rate and the estimated amount of labor required.

- Consider Warranty Coverage: Consider any warranty coverage that may apply.

8.3. Cost-Saving Strategies

Here are some cost-saving strategies for ERLC repairs:

- Do-It-Yourself Repairs: Perform simple repairs yourself, such as replacing sensors or repairing wiring.

- Shop Around: Shop around for the best prices on parts and labor.

- Use Coupons and Discounts: Use coupons and discounts whenever possible.

- Consider Used Parts: Consider using used parts from a reputable source.

9. Car Command ERLC and Vehicle Performance Enhancement

How can proper maintenance and repair of your car command ERLC enhance your vehicle’s performance?

Proper maintenance and repair of your car command ERLC can significantly enhance your vehicle’s performance in several ways:

- Improved Fuel Efficiency: A properly functioning ERLC can optimize fuel injection and ignition timing, leading to improved fuel efficiency.

- Increased Power and Acceleration: A properly functioning ERLC can ensure that the engine is producing maximum power, resulting in increased acceleration.

- Smoother Idle: A properly functioning ERLC can maintain a smooth and stable idle.

- Reduced Emissions: A properly functioning ERLC can ensure that the engine is meeting emissions standards, reducing pollution.

- Enhanced Reliability: A properly functioning ERLC can help prevent costly repairs down the line by detecting and addressing potential problems early.

9.1. Optimizing Fuel Efficiency

A properly functioning ERLC can optimize fuel efficiency by:

- Controlling Fuel Injection: Precisely controlling the amount of fuel injected into the cylinders.

- Adjusting Ignition Timing: Adjusting the ignition timing for optimal combustion.

- Managing Air-Fuel Mixture: Managing the air-fuel mixture to ensure efficient combustion.

9.2. Maximizing Power and Acceleration

A properly functioning ERLC can maximize power and acceleration by:

- Optimizing Spark Timing: Optimizing spark timing for maximum power output.

- Adjusting Fuel Delivery: Adjusting fuel delivery to match the engine’s needs.

- Controlling Boost Pressure: Controlling boost pressure in turbocharged engines.

9.3. Achieving a Smooth Idle

A properly functioning ERLC can achieve a smooth idle by:

- Controlling Idle Speed: Controlling the idle speed to prevent stalling.

- Adjusting Airflow: Adjusting airflow to maintain a stable idle.

- Compensating for Loads: Compensating for loads, such as air conditioning.

9.4. Minimizing Emissions

A properly functioning ERLC can minimize emissions by:

- Controlling EGR Valve: Controlling the EGR (Exhaust Gas Recirculation) valve.

- Managing Catalytic Converter: Managing the catalytic converter.

- Adjusting Air-Fuel Ratio: Adjusting the air-fuel ratio for optimal combustion.

9.5. Ensuring Long-Term Reliability

A properly functioning ERLC can ensure long-term reliability by:

- Monitoring Engine Health: Monitoring engine health and detecting potential problems early.

- Preventing Damage: Preventing damage to other engine components.

- Extending Engine Life: Extending engine life.

10. FAQs About Car Command ERLC

What are some frequently asked questions about car command ERLC systems?

Here are some frequently asked questions about car command ERLC systems:

-

What is a car command ERLC?

The car command ERLC (Engine Running Logic Controller) is the computer that controls your car’s engine.

-

What are the symptoms of a faulty ERLC?

Symptoms include a check engine light, poor fuel economy, rough idle, reduced performance, and starting problems.

-

How can I diagnose an ERLC problem?

You can diagnose an ERLC problem by retrieving diagnostic trouble codes (DTCs) with a scan tool and testing sensors and components.

-

Can I repair an ERLC myself?

Simple repairs, such as replacing sensors or repairing wiring, can be done yourself. Complex repairs may require a professional.

-

How much does it cost to repair an ERLC?

Repair costs can range from $100 to $2000, depending on the issue.

-

How can I prevent ERLC problems?

Prevent ERLC problems by following the manufacturer’s recommended maintenance schedule and addressing issues promptly.

-

Where can I buy ERLC parts and tools?

You can buy ERLC parts and tools from CARDIAGTECH.BIZ.

-

What is the difference between an ERLC and an ECM?

ERLC (Engine Running Logic Controller) and ECM (Engine Control Module) are often used interchangeably to refer to the computer that controls the engine.

-

How do I know if my ERLC needs to be replaced?

Signs include multiple sensor failures, inability to communicate, physical damage, and recurring issues.

-

Can a bad ERLC affect my car’s transmission?

Yes, a bad ERLC can affect your car’s transmission, as it controls many aspects of the vehicle’s overall performance.

10.1. More In-Depth Answers

Let’s dive deeper into these FAQs for a more thorough understanding:

-

What is a car command ERLC?

The Engine Running Logic Controller (ERLC) is the central processing unit of your car’s engine management system. It receives data from various sensors, processes that data, and controls the engine’s functions, such as fuel injection, ignition timing, and emissions control.

-

What are the symptoms of a faulty ERLC?

A faulty ERLC can manifest in numerous ways, including:

- Illuminated check engine light

- Reduced fuel economy

- Rough or unstable idle

- Hesitation or lack of power during acceleration

- Difficulty starting the engine

- Engine stalling

- Failure to pass emissions tests

-

How can I diagnose an ERLC problem?

Diagnosing an ERLC problem typically involves:

- Visual inspection of the ERLC and related wiring

- Retrieving diagnostic trouble codes (DTCs) using a scan tool

- Researching the meaning of the DTCs

- Testing sensors and components

- Performing a vacuum leak test

- Checking the ERLC software

-

Can I repair an ERLC myself?

Whether you can repair an ERLC yourself depends on the nature of the problem and your mechanical skills. Simple tasks like replacing a faulty sensor or repairing damaged wiring can often be done by a DIYer. However, more complex repairs, such as reflashing the ERLC or replacing the ERLC module, may require specialized tools and expertise.

-

How much does it cost to repair an ERLC?

The cost to repair an ERLC can vary widely depending on the specific problem and the repair shop you choose. Simple repairs, such as replacing a sensor, may cost $100 to $500. More complex repairs, such as replacing the ERLC module, can cost $500 to $2000 or more.

-

How can I prevent ERLC problems?

You can prevent ERLC problems by:

- Following the manufacturer’s recommended maintenance schedule

- Keeping your car’s sensors clean and in good working order

- Addressing any engine problems promptly

- Using high-quality replacement parts

- Keeping your car’s wiring in good condition

-

Where can I buy ERLC parts and tools?

You can buy ERLC parts and tools from CARDIAGTECH.BIZ. We offer a wide selection of high-quality diagnostic tools, replacement parts, and technical support to help you diagnose and repair ERLC issues efficiently and effectively.

-

What is the difference between an ERLC and an ECM?

While the terms are often used interchangeably, there can be subtle differences. Generally, ECM (Engine Control Module) is a more generic term, while ERLC (Engine Running Logic Controller) might refer to a specific type or brand of ECM. Both essentially perform the same function: managing the engine’s operation.

-

How do I know if my ERLC needs to be replaced?

Signs that your ERLC may need to be replaced include:

- Multiple sensor failures with no apparent cause

- Inability to communicate with the ERLC using a scan tool

- Physical damage to the ERLC

- Recurring engine problems that cannot be resolved by other repairs

-

Can a bad ERLC affect my car’s transmission?

Yes, a bad ERLC can affect your car’s transmission. The ERLC communicates with the transmission control module (TCM) to coordinate engine and transmission operation. A faulty ERLC can send incorrect signals to the TCM, leading to shifting problems, reduced performance, and damage to the transmission.

Conclusion

Fixing your car command ERLC requires a systematic approach, the right tools, and a good understanding of the system. By following the steps outlined in this guide, you can diagnose and resolve many ERLC issues effectively. Remember, CARDIAGTECH.BIZ is here to support you with high-quality diagnostic tools, replacement parts, and expert technical support.

Don’t let car command ERLC problems slow you down. Contact CARDIAGTECH.BIZ today at +1 (641) 206-8880 or visit our website at CARDIAGTECH.BIZ for all your automotive diagnostic and repair needs. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let us help you keep your vehicle running smoothly and efficiently.

A skilled mechanic diligently working on a car engine, highlighting the precision and expertise needed for effective Engine Running Logic Controller (ERLC) diagnostics and repairs.

Address your automotive needs today and experience the CARDIAGTECH.BIZ difference.