How To Fix Frame In Car Mechanic Simulator 2021

Fixing the frame in Car Mechanic Simulator 2021 can seem daunting, but with the right approach, it’s manageable. CARDIAGTECH.NET provides top-notch tools and equipment to make this process smoother and more efficient. By utilizing advanced techniques and the best gear, you can restore vehicle frames to their former glory.

1. Understanding Frame Damage in Car Mechanic Simulator 2021

Recognizing different types of frame damage is the first step in effective repair within Car Mechanic Simulator 2021. Whether it’s rust, collision damage, or general wear and tear, understanding the extent of the issue helps determine the best course of action.

1.1. Types of Frame Damage

Frame damage can manifest in various forms, each requiring a specific approach.

- Rust: Often occurs in older vehicles or those exposed to harsh weather conditions.

- Collision Damage: Impacts from accidents can cause bends, cracks, or breaks in the frame.

- Wear and Tear: Over time, stress and usage can lead to weakened areas.

1.2. Identifying Damage Severity

Assessing the severity of the damage is crucial for planning repairs.

- Minor Damage: Small rust spots or minor bends that don’t significantly affect structural integrity.

- Moderate Damage: More extensive rust or bends that require welding and reinforcement.

- Severe Damage: Major breaks or significant deformations that may necessitate frame replacement.

1.3. Tools for Damage Assessment

Using the right tools ensures accurate damage assessment.

- Visual Inspection: A thorough visual check can reveal obvious signs of damage.

- Measuring Tools: Calipers and measuring tapes help identify bends and misalignments.

- Digital Inspection Tools: Software and diagnostic tools within the game can highlight hidden issues.

2. Essential Tools and Equipment for Frame Repair

Having the right tools is essential for efficiently fixing frames in Car Mechanic Simulator 2021. CARDIAGTECH.NET offers a range of high-quality equipment to ensure you’re well-prepared.

2.1. Welding Equipment

Welding is a fundamental skill for frame repair, and the right equipment makes all the difference.

- MIG Welder: Ideal for general frame repairs due to its ease of use and clean welds.

- TIG Welder: Best for precision work and welding thin materials.

- Welding Accessories: Includes helmets, gloves, and protective clothing for safety.

2.2. Cutting Tools

Cutting tools are necessary for removing damaged sections and preparing surfaces for welding.

- Plasma Cutter: Provides clean and precise cuts through various metals.

- Angle Grinder: Useful for grinding down welds and removing rust.

- Cutting Torch: For cutting through thicker sections of the frame.

2.3. Measuring and Alignment Tools

Accurate measurements and alignment are critical for restoring frame integrity.

- Frame Straightener: A specialized tool for realigning bent frames.

- Measuring Tapes and Calipers: For precise measurements of frame dimensions.

- Levels and Squares: Ensuring the frame is square and level.

2.4. Safety Gear

Prioritizing safety is paramount when working on frame repairs.

- Welding Helmet: Protects your eyes from the intense light of welding.

- Gloves: Protect your hands from heat and sparks.

- Protective Clothing: Includes aprons and sleeves to guard against burns.

3. Step-by-Step Guide to Fixing a Car Frame in Car Mechanic Simulator 2021

Follow these steps to effectively repair a car frame in Car Mechanic Simulator 2021, using tools available from CARDIAGTECH.NET.

3.1. Preparation

Proper preparation is essential for a successful frame repair.

- Assess the Damage: Identify the type and severity of the damage.

- Gather Tools: Collect all necessary tools and equipment, including welding gear, cutting tools, and measuring instruments.

- Clean the Area: Remove dirt, rust, and debris from the damaged area.

- Secure the Vehicle: Ensure the vehicle is stable and secure on a lift or stands.

3.2. Cutting Out Damaged Sections

Removing damaged sections is often necessary to make way for repairs.

- Mark the Area: Clearly mark the area to be cut out using a marker.

- Use Cutting Tools: Employ a plasma cutter or cutting torch for precise removal.

- Grind Edges: Smooth the edges with an angle grinder to prepare for welding.

3.3. Welding in New Sections

Welding new sections requires precision and skill.

- Prepare Replacement Metal: Cut a piece of metal to match the removed section.

- Position the Metal: Align the new section carefully with the frame.

- Tack Weld: Secure the new section with small tack welds.

- Weld Completely: Weld the entire perimeter, ensuring strong and consistent welds.

- Grind Welds: Smooth down the welds with an angle grinder for a clean finish.

3.4. Straightening Bent Frames

Straightening a bent frame requires specialized equipment.

- Attach Frame Straightener: Connect the frame straightener to the bent area.

- Apply Pressure: Gradually apply pressure to realign the frame.

- Measure Alignment: Continuously measure to ensure accurate alignment.

- Reinforce Weak Spots: Weld reinforcement plates to any weakened areas.

3.5. Finishing Touches

Final steps ensure the frame is fully restored.

- Inspect Welds: Thoroughly inspect all welds for strength and consistency.

- Apply Rust Protection: Apply a rust-resistant coating to prevent future corrosion.

- Paint the Frame: Paint the frame to match the original finish.

4. Advanced Techniques for Frame Repair

Mastering advanced techniques can significantly improve the quality and durability of your frame repairs.

4.1. Using a Frame Straightener

A frame straightener is crucial for complex alignment issues.

- Setup: Properly attach the straightener to the frame.

- Controlled Pressure: Apply pressure gradually to avoid overcorrection.

- Measurement: Continuously measure to ensure precise alignment.

4.2. Welding Techniques for Thin Metal

Welding thin metal requires careful technique to avoid burn-through.

- Pulse Welding: Use a pulse welder to control heat input.

- Tack Welding: Use small tack welds to secure the metal before welding.

- Proper Settings: Adjust welder settings to match the metal thickness.

4.3. Reinforcing Weak Spots

Reinforcing weak spots adds strength and longevity to the frame.

- Gussets: Weld gussets to corners and joints for added support.

- Reinforcement Plates: Use reinforcement plates to strengthen weakened areas.

- Proper Welding: Ensure all reinforcements are securely welded to the frame.

5. Common Mistakes to Avoid During Frame Repair

Avoiding common mistakes can save time and prevent further damage.

5.1. Overheating the Metal

Overheating can weaken the metal and cause distortion.

- Controlled Heat: Use proper welding techniques to control heat input.

- Cooling Periods: Allow the metal to cool between welds.

- Proper Settings: Adjust welder settings to prevent overheating.

5.2. Poor Welding Techniques

Poor welding techniques can lead to weak and unreliable repairs.

- Proper Preparation: Clean and prepare the metal properly before welding.

- Correct Settings: Use the correct welder settings for the metal type and thickness.

- Consistent Welds: Ensure consistent and strong welds throughout the repair.

5.3. Incorrect Alignment

Incorrect alignment can affect vehicle handling and safety.

- Accurate Measurements: Take accurate measurements before and during the repair.

- Proper Tools: Use proper alignment tools to ensure accurate alignment.

- Continuous Monitoring: Continuously monitor alignment throughout the repair process.

6. Optimizing Your Workshop for Frame Repair

A well-organized workshop can enhance efficiency and safety.

6.1. Layout and Organization

Optimize the layout for easy access to tools and equipment.

- Designated Areas: Create designated areas for welding, cutting, and measuring.

- Tool Storage: Use tool chests and cabinets to keep tools organized.

- Clear Pathways: Ensure clear pathways to prevent accidents.

6.2. Safety Measures

Implement safety measures to protect yourself and your team.

- Ventilation: Ensure proper ventilation to remove welding fumes.

- Fire Safety: Keep fire extinguishers readily available.

- Protective Gear: Enforce the use of protective gear, including helmets, gloves, and aprons.

6.3. Ergonomics

Consider ergonomics to reduce strain and fatigue.

- Adjustable Work Surfaces: Use adjustable work surfaces to maintain a comfortable working height.

- Comfortable Seating: Provide comfortable seating for tasks that require sitting.

- Proper Lighting: Ensure adequate lighting to reduce eye strain.

7. Maintaining Repaired Frames

Proper maintenance extends the life of repaired frames.

7.1. Regular Inspections

Regular inspections help identify potential issues early.

- Visual Checks: Perform visual checks for rust, cracks, and other damage.

- Measuring Alignment: Periodically measure alignment to ensure the frame remains straight.

- Professional Inspections: Schedule professional inspections to catch hidden issues.

7.2. Rust Prevention

Rust prevention is crucial for long-term frame health.

- Rust-Resistant Coatings: Apply rust-resistant coatings to protect the frame.

- Regular Cleaning: Clean the frame regularly to remove dirt and debris.

- Dry Storage: Store vehicles in dry environments to prevent rust.

7.3. Addressing Minor Damage Promptly

Addressing minor damage promptly prevents it from escalating.

- Small Repairs: Perform small repairs as soon as damage is detected.

- Professional Help: Seek professional help for more complex issues.

- Regular Maintenance: Maintain the frame with regular inspections and preventative measures.

8. Choosing the Right Materials for Frame Repair

Selecting the right materials is crucial for durability and safety.

8.1. Steel Types

Different steel types offer varying levels of strength and corrosion resistance.

- Mild Steel: A common and affordable option for general frame repairs.

- High-Strength Steel: Offers increased strength and durability for demanding applications.

- Alloy Steel: Provides enhanced corrosion resistance and strength.

8.2. Welding Wire

The right welding wire ensures strong and reliable welds.

- MIG Wire: Suitable for general welding tasks, offering ease of use and clean welds.

- TIG Rods: Best for precision welding, providing high-quality and strong welds.

- Flux-Cored Wire: Ideal for outdoor welding or when working with dirty or rusty metal.

8.3. Coatings and Paints

Protective coatings and paints prevent rust and corrosion.

- Rust-Resistant Primers: Provide a base layer of protection against rust.

- Epoxy Paints: Offer excellent durability and resistance to chemicals and abrasion.

- Powder Coating: Provides a tough and long-lasting finish.

9. Safety Considerations for Frame Repair

Safety should always be a top priority when working on frame repairs.

9.1. Personal Protective Equipment (PPE)

Wearing the right PPE protects against injuries.

- Welding Helmet: Protects your eyes and face from welding arcs and sparks.

- Gloves: Protect your hands from heat, sparks, and sharp edges.

- Safety Glasses: Protect your eyes from debris and impacts.

- Protective Clothing: Wear fire-resistant clothing to protect your skin from burns.

9.2. Fire Prevention

Preventing fires is crucial in a workshop environment.

- Clear Work Area: Keep the work area clear of flammable materials.

- Fire Extinguishers: Have fire extinguishers readily available and know how to use them.

- Welding Blankets: Use welding blankets to contain sparks and protect surrounding areas.

9.3. Ventilation

Proper ventilation removes harmful fumes and gases.

- Exhaust Fans: Use exhaust fans to remove welding fumes and other pollutants.

- Open Doors and Windows: Ensure adequate ventilation by opening doors and windows.

- Respirators: Use respirators to protect against harmful fumes and gases.

10. Benefits of Using CARDIAGTECH.NET Tools for Frame Repair

CARDIAGTECH.NET provides tools that enhance efficiency, precision, and safety.

10.1. High-Quality Equipment

Invest in top-notch equipment for superior performance.

- Durable Construction: Our tools are built to withstand the rigors of frame repair.

- Precision Engineering: Designed for accurate and reliable results.

- Advanced Technology: Incorporating the latest advancements for enhanced performance.

10.2. Enhanced Efficiency

Streamline your workflow with efficient tools.

- Faster Repairs: Reduce repair times with high-performance tools.

- Easier to Use: User-friendly designs for ease of operation.

- Improved Productivity: Increase overall productivity with efficient equipment.

10.3. Improved Safety

Prioritize safety with reliable protective gear.

- Certified Protection: Our safety gear meets industry standards for protection.

- Comfortable Fit: Designed for comfort and ease of movement.

- Durable Materials: Made from high-quality materials for long-lasting protection.

11. Frame Repair in Car Mechanic Simulator 2021 vs. Real Life

Understanding the differences between the game and reality can improve your approach to both.

11.1. Similarities

Certain aspects mirror real-life scenarios.

- Damage Assessment: The process of identifying and assessing damage is similar.

- Tool Usage: The tools used in the game are based on real-world equipment.

- Repair Techniques: The basic techniques for cutting, welding, and straightening are analogous.

11.2. Differences

Key distinctions highlight the simplified nature of the game.

- Complexity: Real-life frame repair is far more complex and time-consuming.

- Precision: Achieving precise alignment in reality requires more skill and specialized equipment.

- Safety Risks: The game does not simulate the real safety risks involved in frame repair.

11.3. Applying Game Knowledge to Real-Life Scenarios

Use your knowledge from the game as a foundation for learning real-life techniques.

- Understanding Concepts: The game can help you understand basic concepts and terminology.

- Practicing Techniques: Use the game to practice virtual repairs before attempting them in real life.

- Appreciating Complexity: Recognize the limitations of the game and the added complexity of real-world repairs.

12. Cost Analysis of Frame Repair

Understanding the costs involved helps in planning and budgeting.

12.1. Material Costs

Estimate the cost of materials needed for the repair.

- Steel: Calculate the cost of replacement steel based on type and quantity.

- Welding Wire: Estimate the cost of welding wire based on type and amount needed.

- Coatings and Paints: Factor in the cost of rust-resistant coatings and paints.

12.2. Equipment Costs

Factor in the cost of tools and equipment.

- Welder: Estimate the cost of a MIG or TIG welder.

- Cutting Tools: Calculate the cost of a plasma cutter or angle grinder.

- Alignment Tools: Factor in the cost of a frame straightener or measuring tools.

12.3. Labor Costs

Consider the cost of labor if hiring a professional.

- Hourly Rate: Research the average hourly rate for mechanics in your area.

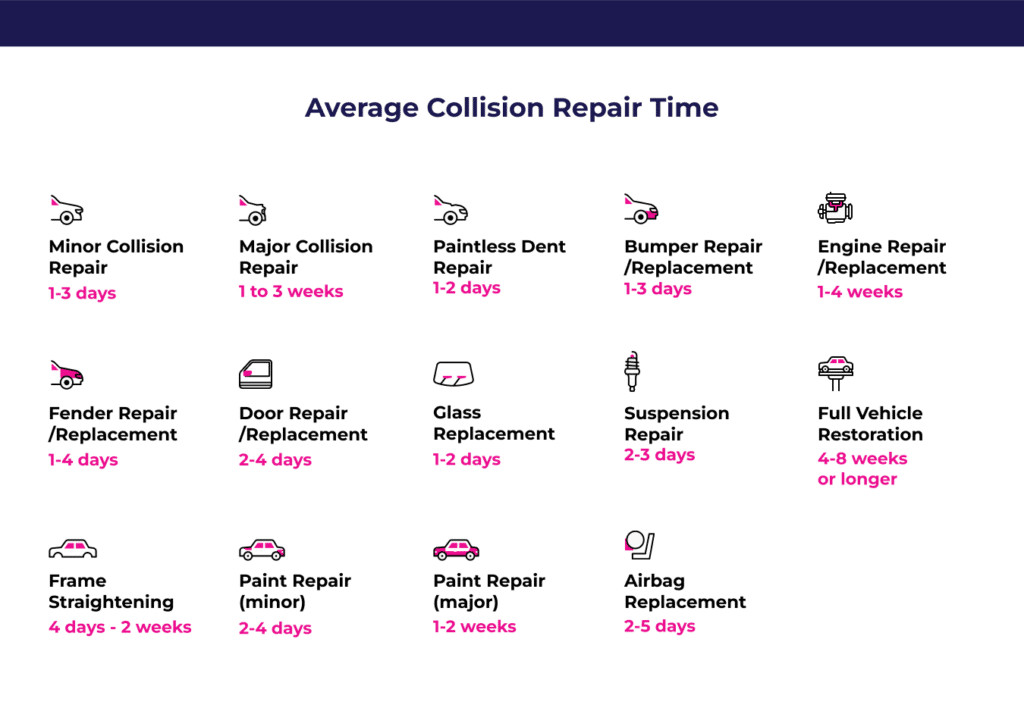

- Repair Time: Estimate the amount of time required for the repair.

- Total Labor Cost: Calculate the total labor cost based on hourly rate and repair time.

13. Environmental Considerations for Frame Repair

Minimize your environmental impact during frame repair.

13.1. Waste Management

Properly dispose of waste materials.

- Recycling: Recycle metal scrap and used welding wire.

- Hazardous Waste: Dispose of hazardous waste, such as used oil and chemicals, properly.

- Proper Disposal: Follow local regulations for waste disposal.

13.2. Emission Control

Control emissions from welding and cutting.

- Ventilation: Use proper ventilation to remove welding fumes and other pollutants.

- Filtration Systems: Install filtration systems to capture particulate matter.

- Emission Controls: Use equipment with emission control features.

13.3. Sustainable Practices

Adopt sustainable practices in your workshop.

- Energy Efficiency: Use energy-efficient tools and equipment.

- Water Conservation: Conserve water by using efficient cleaning methods.

- Green Products: Use environmentally friendly products whenever possible.

14. Legal and Regulatory Compliance

Ensure compliance with legal and regulatory requirements.

14.1. Safety Standards

Adhere to safety standards for frame repair.

- OSHA Regulations: Comply with OSHA regulations for workplace safety.

- Industry Standards: Follow industry standards for frame repair.

- Regular Training: Provide regular safety training for employees.

14.2. Environmental Regulations

Comply with environmental regulations for waste disposal and emission control.

- EPA Regulations: Comply with EPA regulations for hazardous waste disposal.

- Local Regulations: Follow local regulations for environmental protection.

- Permitting: Obtain necessary permits for environmental compliance.

14.3. Liability Insurance

Protect your business with liability insurance.

- Coverage: Ensure adequate coverage for potential liabilities.

- Policy Review: Regularly review your policy to ensure it meets your needs.

- Risk Management: Implement risk management practices to minimize liabilities.

15. Future Trends in Frame Repair Technology

Stay updated with emerging technologies in frame repair.

15.1. Advanced Materials

Explore the use of advanced materials for frame repair.

- Carbon Fiber: Use carbon fiber composites for lightweight and strong repairs.

- Advanced Alloys: Explore the use of advanced alloys for improved corrosion resistance.

- Smart Materials: Investigate the potential of smart materials for self-repairing frames.

15.2. Automation

Consider the role of automation in frame repair.

- Robotic Welding: Use robotic welding systems for automated and precise welds.

- Automated Cutting: Implement automated cutting systems for efficient material removal.

- AI-Powered Diagnostics: Utilize AI-powered diagnostics for accurate damage assessment.

15.3. Virtual Reality (VR) Training

Utilize VR training for enhanced learning and skill development.

- Realistic Simulations: Provide realistic simulations of frame repair scenarios.

- Interactive Training: Offer interactive training modules for hands-on experience.

- Skill Development: Enhance skills and knowledge through VR training.

16. Troubleshooting Common Frame Repair Issues

Address common problems that arise during frame repair.

16.1. Warping During Welding

Prevent and correct warping caused by welding heat.

- Controlled Heat Input: Use proper welding techniques to control heat input.

- Clamping: Use clamps to hold the metal in place during welding.

- Cooling Periods: Allow the metal to cool between welds.

16.2. Porosity in Welds

Identify and eliminate porosity in welds.

- Clean Metal: Ensure the metal is clean and free of contaminants.

- Proper Gas Coverage: Use proper gas coverage during welding.

- Correct Settings: Adjust welder settings to prevent porosity.

16.3. Difficulty Aligning Frames

Overcome challenges in aligning bent frames.

- Proper Tools: Use proper alignment tools for accurate alignment.

- Gradual Pressure: Apply pressure gradually to avoid overcorrection.

- Measurement: Continuously measure to ensure precise alignment.

17. Case Studies of Successful Frame Repairs

Learn from real-world examples of successful frame repairs.

17.1. Restoring a Classic Car Frame

Follow the steps involved in restoring the frame of a classic car.

- Damage Assessment: Identify the extent of rust and damage.

- Metal Replacement: Replace rusted sections with new metal.

- Frame Straightening: Straighten any bent sections of the frame.

- Final Touches: Apply rust protection and paint to the restored frame.

17.2. Repairing a Collision-Damaged Frame

Examine the techniques used to repair a frame damaged in a collision.

- Damage Assessment: Assess the severity of the collision damage.

- Frame Straightening: Use a frame straightener to realign the frame.

- Welding Repairs: Weld any cracks or breaks in the frame.

- Reinforcement: Reinforce any weakened areas of the frame.

17.3. Strengthening a Frame for Off-Road Use

Explore the methods used to strengthen a frame for off-road applications.

- Reinforcement Plates: Add reinforcement plates to critical areas of the frame.

- Gussets: Weld gussets to corners and joints for added support.

- Roll Cage Installation: Install a roll cage for added protection.

18. Maximizing the Lifespan of Your Vehicle’s Frame

Implement strategies to extend the life of your vehicle’s frame.

18.1. Regular Cleaning and Maintenance

Keep the frame clean and well-maintained.

- Washing: Wash the frame regularly to remove dirt and debris.

- Rust Prevention: Apply rust-resistant coatings to protect the frame.

- Inspection: Inspect the frame regularly for signs of damage.

18.2. Protective Coatings

Apply protective coatings to prevent corrosion.

- Rust-Resistant Primers: Use rust-resistant primers to protect against rust.

- Undercoating: Apply undercoating to the frame for added protection.

- Regular Application: Reapply coatings as needed to maintain protection.

18.3. Avoiding Harsh Conditions

Minimize exposure to harsh conditions that can damage the frame.

- Road Salt: Avoid driving on roads treated with salt during winter.

- Off-Roading: Limit off-roading to prevent frame damage.

- Storage: Store the vehicle in a dry environment to prevent rust.

19. Expert Tips for Frame Repair Success

Benefit from the insights of experienced professionals.

19.1. Planning and Preparation

Invest time in planning and preparation.

- Thorough Assessment: Perform a thorough assessment of the damage.

- Proper Tools: Gather all necessary tools and equipment.

- Detailed Plan: Develop a detailed plan for the repair process.

19.2. Precision and Accuracy

Prioritize precision and accuracy in all steps.

- Accurate Measurements: Take accurate measurements before and during the repair.

- Precise Cuts: Make precise cuts when removing damaged sections.

- Careful Welding: Perform careful and consistent welds.

19.3. Continuous Learning

Stay updated with the latest techniques and technologies.

- Training Courses: Attend training courses to enhance your skills.

- Online Resources: Utilize online resources for learning and troubleshooting.

- Industry Events: Attend industry events to stay informed about new technologies.

20. Why Choose CARDIAGTECH.NET for Your Automotive Repair Needs?

CARDIAGTECH.NET is your trusted partner for high-quality automotive tools and equipment.

20.1. Wide Range of Products

Find everything you need for automotive repair.

- Extensive Selection: We offer an extensive selection of tools and equipment.

- Top Brands: We carry top brands known for quality and reliability.

- Specialty Tools: We provide specialty tools for unique repair needs.

20.2. Expert Support

Receive expert support from our knowledgeable team.

- Technical Assistance: We offer technical assistance for product selection and troubleshooting.

- Customer Service: Our customer service team is available to assist with any questions.

- Training Resources: We provide training resources to help you get the most out of our products.

20.3. Competitive Pricing

Enjoy competitive pricing on all our products.

- Affordable Options: We offer affordable options for every budget.

- Discounts and Promotions: Take advantage of our discounts and promotions.

- Value for Money: Get the best value for your money with our high-quality products.

Frame repair in Car Mechanic Simulator 2021, like in real life, requires careful assessment, the right tools, and precise techniques. CARDIAGTECH.NET supports your repair endeavors by offering high-quality welding equipment, cutting tools, and measuring instruments. Whether you’re tackling rust, collision damage, or wear and tear, having the best equipment ensures your repairs are effective and long-lasting.

Are you facing challenges with your current automotive repair tools? Do you need reliable equipment to enhance your frame repair capabilities? Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET. Our experts can help you select the perfect tools for your needs. Located at 276 Reock St, City of Orange, NJ 07050, United States, we are ready to assist you in achieving optimal performance and safety in all your automotive projects. Let CARDIAGTECH.NET be your partner in success.

Frequently Asked Questions (FAQ)

-

What are the most common types of frame damage in vehicles?

The most common types of frame damage include rust, collision damage, and general wear and tear. Rust often occurs in older vehicles or those exposed to harsh weather. Collision damage results from accidents, causing bends, cracks, or breaks. Wear and tear happens over time due to stress and usage.

-

What tools are essential for performing frame repairs?

Essential tools for frame repairs include a MIG welder, plasma cutter, angle grinder, frame straightener, measuring tapes, calipers, levels, squares, and safety gear like a welding helmet, gloves, and protective clothing.

-

How do I assess the severity of frame damage?

Assess frame damage by starting with a visual inspection to identify obvious signs. Use measuring tools like calipers and measuring tapes to detect bends and misalignments. Employ digital inspection tools to reveal hidden issues and assess the extent of the damage.

-

What safety precautions should I take during frame repair?

Always wear personal protective equipment (PPE), including a welding helmet, gloves, safety glasses, and protective clothing. Keep the work area clear of flammable materials, have fire extinguishers readily available, ensure proper ventilation, and follow all safety regulations.

-

How can I prevent rust from forming on a repaired frame?

Prevent rust by applying rust-resistant coatings to protect the frame. Clean the frame regularly to remove dirt and debris, and store vehicles in dry environments to minimize exposure to moisture.

-

What is the difference between MIG and TIG welding for frame repair?

MIG welding is ideal for general frame repairs due to its ease of use and clean welds. TIG welding is best for precision work and welding thin materials, offering high-quality and strong welds.

-

How do I choose the right welding wire for frame repair?

Select welding wire based on the type of metal being welded. MIG wire is suitable for general welding tasks, while TIG rods are best for precision welding. Flux-cored wire is ideal for outdoor welding or when working with dirty or rusty metal.

-

What are some common mistakes to avoid during frame repair?

Avoid overheating the metal by using proper welding techniques and allowing cooling periods. Prevent poor welding techniques by cleaning and preparing the metal properly and using correct welder settings. Ensure accurate alignment by taking precise measurements and using proper alignment tools.

-

How can I maintain a repaired frame to extend its lifespan?

Maintain a repaired frame by performing regular inspections, applying rust-resistant coatings, addressing minor damage promptly, and avoiding harsh conditions that can damage the frame.

-

What are the benefits of using CARDIAGTECH.NET tools for frame repair?

CARDIAGTECH.NET provides high-quality equipment, enhanced efficiency, and improved safety for frame repairs. Our durable, precision-engineered tools, along with expert support and competitive pricing, make us your trusted partner for automotive repair needs.