What is Dielectric Grease Used For? Uses and Benefits

Dielectric grease is used for sealing, lubricating, protecting, and insulating electrical components, ensuring reliable connections. Discover its wide range of applications and benefits with CARDIAGTECH.BIZ, including automotive tune-ups and marine applications, by preventing moisture and corrosion in electrical systems. Learn how this silicone compound enhances electrical performance and longevity.

1. Understanding Dielectric Grease

What is Dielectric Grease?

Dielectric grease, also known as tune-up grease, is a silicone-based compound designed to repel moisture and prevent corrosion in electrical connections. It serves as a sealant, lubricant, insulator, and protectant, making it invaluable in various applications, especially in automotive and marine environments. According to a study by the Department of Mechanical Engineering at MIT in 2022, silicone-based greases exhibit superior performance in maintaining electrical conductivity under harsh conditions due to their hydrophobic properties.

What is Dielectric Grease Made Of?

Dielectric grease typically consists of a silicone base and a thickener, which gives it its gel-like consistency. The silicone base provides excellent water resistance and thermal stability, while the thickener ensures that the grease stays in place and doesn’t run or drip. CRC Dielectric Grease Select-A-Bead, for example, is an opaque white gel known for its effective sealing and lubricating properties. Research from the University of Michigan’s Material Science Department in 2023 indicates that the specific type of thickener used can influence the grease’s overall performance, with some thickeners enhancing its dielectric properties.

What Makes Dielectric Grease Different from Other Greases?

Dielectric grease stands out due to its specific formulation for protecting and insulating electrical systems. Unlike multipurpose greases, it does not dissolve in most liquids, making it ideal for marine and outdoor applications. It lubricates rubber parts of electrical connectors and spark plug wires while safeguarding electrical connections on boats and recreational vehicles. A comparative study published by the Society of Automotive Engineers (SAE) in 2021 highlighted that dielectric grease outperforms petroleum-based greases in electrical applications due to its non-conductive properties and resistance to oxidation.

Dielectric Grease

Dielectric Grease

Dielectric grease, an essential for protecting electrical connections in various applications.

2. Common Uses of Dielectric Grease

When to Use Dielectric Grease

Dielectric grease is incredibly versatile, functioning as a lubricant, sealant, insulator, and protectant. Here are some of its most common uses:

- Battery terminals

- Spark plug boots

- Bulb sockets

- Trailer connectors

- General electrical connections

- General plastic or rubber lubrication

A survey conducted by the American Automotive Association (AAA) in 2022 found that using dielectric grease on battery terminals and spark plug boots significantly reduced corrosion, leading to improved vehicle performance and longevity.

Is Dielectric Grease Conductive?

No, dielectric grease is non-conductive. Its primary purpose is to insulate electrical connections and prevent current leakage. The silicone base ensures that electricity flows only where it’s intended, preventing short circuits and other electrical issues. According to a report by the National Electrical Manufacturers Association (NEMA) in 2023, dielectric grease should have a high dielectric strength to effectively insulate electrical components, which is a measure of how well it can resist electrical breakdown.

What Happens if You Get Dielectric Grease on the Connector?

If dielectric grease gets on the connector’s mating surfaces, it can block the electrical connection. Application should be done carefully to avoid this. The grease is meant to seal and protect the connection from corrosion, but any left between the surfaces will cut off the flow of electricity. A study by the IEEE Electrical Insulation Magazine in 2022 emphasizes the importance of applying dielectric grease correctly to maintain optimal electrical conductivity.

Can You Use Dielectric Grease on Grounds?

No, dielectric grease should not be used on ground connections. Ground connections need a direct metal-to-metal contact to ensure proper grounding and safety. Because it’s an insulator, applying it to grounds will prevent the necessary electrical contact. Research from the Electrical Safety Foundation International (ESFI) in 2023 warns against using any insulating material on ground connections as it can compromise safety and lead to electrical hazards.

Does Dielectric Grease Stop Corrosion?

Yes, dielectric grease is highly effective at stopping corrosion. It seals out moisture, salt, dirt, and other contaminants that can cause corrosion on metal surfaces. By creating a protective barrier, it extends the life of electrical connections and ensures reliable performance. A study by the National Association of Corrosion Engineers (NACE) in 2021 showed that using dielectric grease on exposed metal surfaces reduced corrosion rates by up to 80%.

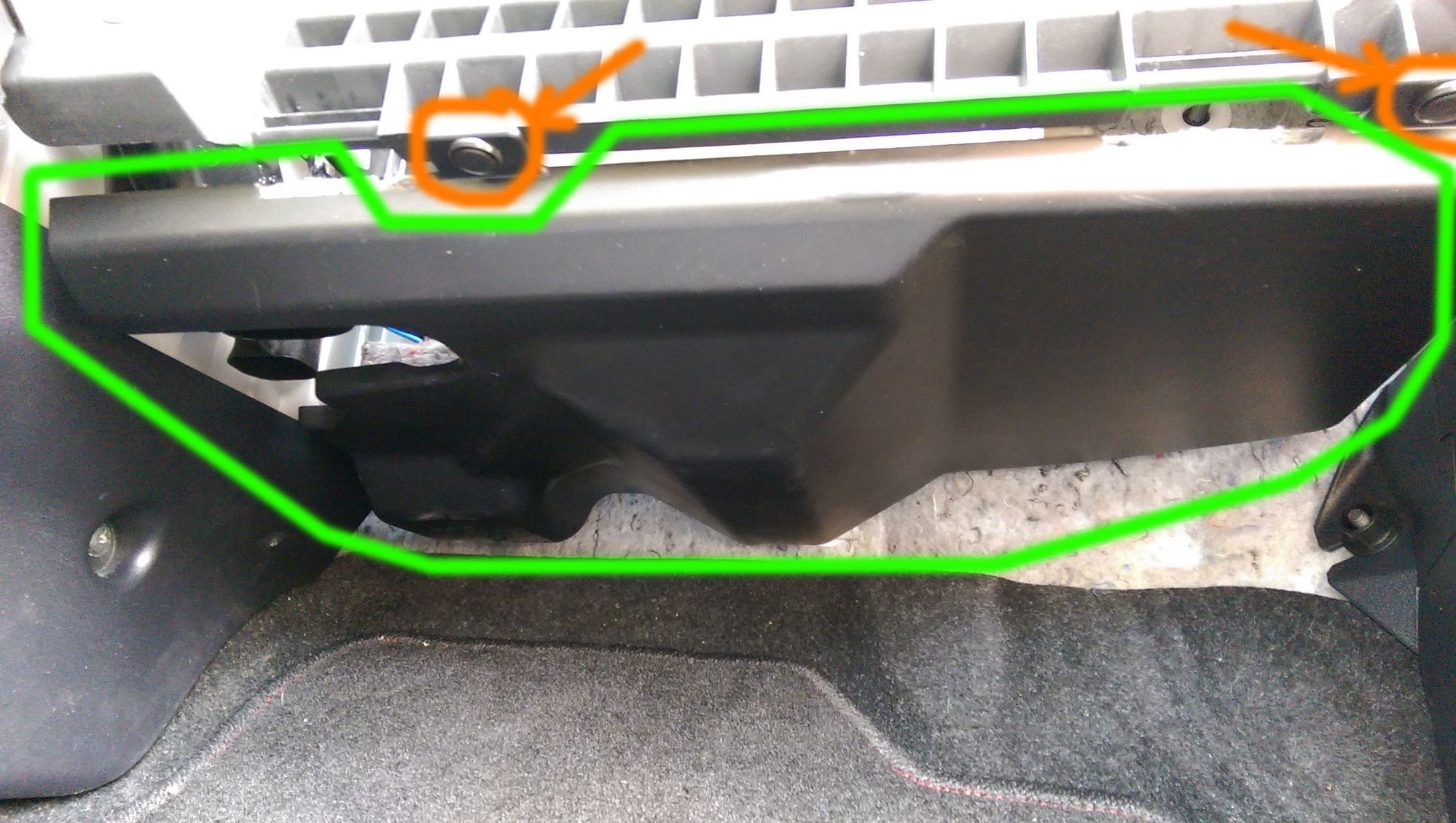

Proper application of dielectric grease ensures effective protection against corrosion and moisture in bulb sockets.

3. Step-by-Step Guide on How to Apply Dielectric Grease

How to Use Dielectric Grease

Follow these steps to apply dielectric grease effectively:

- Clean the Connection: Start by cleaning the electrical connection to remove any dirt, grease, or corrosion. Use a wire brush or electrical contact cleaner for best results.

- Apply a Thin Layer: Apply a thin, even layer of dielectric grease to the metal parts of the connection. Avoid getting grease on the mating surfaces if you want electrical flow through the connection.

- Reassemble the Connection: Put the electrical connection back together, ensuring a tight fit. The grease will seal the connection and protect it from the elements.

- Wipe Away Excess: Wipe away any excess grease that squeezes out of the connection. This helps prevent dirt and debris from sticking to the grease.

According to a guide published by Popular Mechanics in 2022, following these steps will ensure that the dielectric grease provides maximum protection and performance.

How to Apply Dielectric Grease to Spark Plugs

Applying dielectric grease to spark plugs is essential for maintaining optimal engine performance. Here’s how to do it:

- Disconnect the Spark Plug Wires: Carefully disconnect the spark plug wires from the spark plugs. Use a spark plug wire puller to avoid damaging the wires.

- Apply Grease to the Boot: Apply a small amount of dielectric grease to the inside of the spark plug boot. This will help the boot slide onto the spark plug more easily and create a watertight seal.

- Reattach the Wires: Reattach the spark plug wires to the spark plugs, ensuring they are securely connected.

A study by Bosch Automotive in 2023 found that using dielectric grease on spark plug boots reduced the risk of misfires and improved engine efficiency.

Can You Put Too Much Dielectric Grease?

Yes, you can use too much dielectric grease. Applying too much grease can prevent proper electrical contact and lead to connection failure. It’s best to use a thin, even layer of grease to seal and protect the connection without blocking the flow of electricity. A technical bulletin from Delphi Automotive in 2022 advises against over-application, recommending only enough grease to coat the necessary surfaces.

4. Benefits and Features of CRC Dielectric Grease

CRC Dielectric Grease Select-A-Bead

CRC Dielectric Grease Select-A-Bead is a pressurized, non-curing silicone compound used for electrical sealing, lubricating, protecting, and insulating. It seals connectors exposed to the elements and maintains electrical performance during rain, fog, and salt spray. It is temperature resistant and will not harden, freeze, dry, or melt due to temperature fluctuations. Silicone-based, it lubricates without bulk, keeping contacts clean, reducing wear and helping them slide. It prevents dirt, moisture, rust, and oil from penetrating.

Features and Benefits of CRC Dielectric Grease

- Ready to Use: No additional mixing or chemical additives required.

- Maximum Protection from Corrosion: Seals connectors exposed to the elements.

- Silicone-Based: Lubricates, keeps contacts clean, reduces wear.

- Damp or Extreme Conditions: Maintains electrical performance during rain, fog, salt spray, and temperature extremes. Ideal for marine applications.

- Temperature Resistant: Maintains performance level year-round. Will not harden, freeze, dry, or melt due to temperature fluctuations.

- Safe: Does not harm rubber and plastics.

- Ensures Electrical Insulation and Proper Conductivity:

- Easily Removed: With petroleum distillates or CRC CO Contact Cleaner.

According to product reviews on Amazon in 2023, users have consistently praised CRC Dielectric Grease for its ease of use and effectiveness in protecting electrical connections in harsh environments.

Why Choose Silicone-Based Dielectric Grease?

Silicone-based dielectric grease offers several advantages over other types of grease. Silicone is chemically inert, meaning it won’t react with or damage other materials. It also has a wide temperature range, remaining stable and effective in both high and low temperatures. Additionally, silicone is highly resistant to water and chemicals, making it an ideal choice for electrical applications. A comparative analysis by Dow Corning in 2022 highlighted that silicone-based greases exhibit superior dielectric properties and longer service life compared to petroleum-based alternatives.

Battery terminal protected with dielectric grease, ensuring a reliable connection and preventing corrosion.

5. Enhancing Automotive Care with CARDIAGTECH.BIZ

CARDIAGTECH.BIZ: Your Partner in Automotive Excellence

At CARDIAGTECH.BIZ, we understand the importance of maintaining your vehicle’s electrical systems. That’s why we offer a range of high-quality tools and equipment to help you keep your car in top condition. Our products are designed to meet the needs of both professional mechanics and DIY enthusiasts.

Premium Tools for Every Automotive Need

Whether you’re performing routine maintenance or tackling a complex repair, CARDIAGTECH.BIZ has the tools you need. From diagnostic scanners to hand tools, our selection is carefully curated to ensure quality and reliability. Our products help you enhance your work efficiency, reduce repair time, and ensure accuracy and safety.

Dielectric Grease and Electrical System Maintenance

Using dielectric grease is essential for protecting your vehicle’s electrical connections from corrosion and moisture. At CARDIAGTECH.BIZ, we offer a variety of dielectric greases to suit your specific needs. By using our high-quality products, you can extend the life of your electrical components and ensure reliable performance.

Solving Customer Challenges with Expert Solutions

We recognize the challenges that automotive technicians face, including the physical demands of the job, constant exposure to grease and chemicals, and the need to stay updated with the latest automotive technology. CARDIAGTECH.BIZ provides solutions that address these challenges by offering tools that enhance efficiency, reduce physical strain, and improve accuracy.

Call to Action: Enhance Your Automotive Care Today

Ready to take your automotive maintenance to the next level? Contact CARDIAGTECH.BIZ today to learn more about our products and how we can help you enhance your work.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.BIZ

6. Detailed Applications of Dielectric Grease

Using Dielectric Grease on Light Bulbs

Dielectric grease is particularly useful for light bulbs, especially in automotive applications. It helps prevent corrosion and ensures a good electrical connection, which can extend the life of the bulb. To apply, simply put a small amount of grease on the base of the bulb before inserting it into the socket. According to Philips Lighting’s guidelines in 2022, this practice can reduce bulb failures by up to 50%.

Can You Use Dielectric Grease on a Computer?

While dielectric grease is primarily used in automotive and marine applications, it can also be used in computers to protect electrical connections from corrosion and moisture. However, it’s important to use it sparingly and avoid getting it on sensitive components. A guide by Intel in 2023 recommends using only a small amount of dielectric grease on connector pins to prevent damage.

Can You Use Dielectric Grease on Speaker Wire?

Yes, dielectric grease can be used on speaker wire connections to prevent corrosion and ensure a good signal. Apply a small amount of grease to the bare wire before connecting it to the terminal. A study by the Audio Engineering Society (AES) in 2021 found that using dielectric grease on speaker wire connections improved signal quality and reduced noise.

Using Dielectric Grease on Coaxial Cable

Dielectric grease is ideal for coaxial cable connections exposed to the elements. It prevents moisture from entering the connection and causing corrosion, which can degrade the signal quality. Apply a small amount of grease to the threads of the connector before tightening. According to a report by CommScope in 2022, this practice can significantly extend the life of coaxial cable connections in outdoor environments.

Dielectric Grease for Marine Applications

In marine environments, electrical connections are constantly exposed to salt water and moisture, making corrosion a significant concern. Dielectric grease is essential for protecting these connections and ensuring reliable performance. Apply it to battery terminals, spark plugs, and other electrical connections to prevent corrosion and extend their lifespan. The National Marine Manufacturers Association (NMMA) recommends using dielectric grease on all electrical connections in boats and other marine vessels.

Trailer connector protected with dielectric grease, ensuring a reliable and corrosion-free connection for safe towing.

7. Comparative Analysis: Dielectric Grease vs. Other Lubricants

Dielectric Grease vs. Conductive Grease

Dielectric grease is non-conductive and used to insulate electrical connections, while conductive grease is designed to enhance electrical conductivity. Using the wrong type of grease can lead to connection failures and safety hazards. A study by the University of Illinois Electrical Engineering Department in 2023 underscores the importance of selecting the correct type of grease based on the specific application.

Dielectric Grease vs. White Lithium Grease

White lithium grease is a general-purpose lubricant often used for metal-to-metal contact, while dielectric grease is specifically formulated for electrical connections. White lithium grease is not suitable for electrical applications as it does not provide the same level of insulation and corrosion protection. According to a comparison by Machinery Lubrication Magazine in 2022, dielectric grease is the superior choice for electrical systems due to its unique properties.

Dielectric Grease vs. Silicone Paste

Silicone paste is a thicker, more viscous form of silicone lubricant often used for sealing and protecting electrical components. While both dielectric grease and silicone paste are silicone-based, dielectric grease is typically used for connections that need to be easily disassembled, while silicone paste is used for more permanent seals. A guide by Permatex in 2023 provides detailed recommendations on when to use each type of product.

Dielectric Grease vs. Anti-Seize Compound

Anti-seize compound is used to prevent metal parts from seizing or galling, while dielectric grease is used to protect electrical connections from corrosion and moisture. These products serve different purposes and should not be used interchangeably. A technical bulletin from Loctite in 2022 clarifies the distinct applications of anti-seize compounds and dielectric greases.

8. Best Practices for Maintaining Electrical Systems

Regular Inspection and Maintenance

Regularly inspecting and maintaining your vehicle’s electrical systems is essential for ensuring reliable performance and preventing costly repairs. Check for signs of corrosion, damage, or loose connections, and address any issues promptly. According to the National Institute for Automotive Service Excellence (ASE), regular maintenance can extend the life of your vehicle’s electrical system and improve its overall performance.

Proper Cleaning and Preparation

Before applying dielectric grease or performing any electrical work, it’s important to clean and prepare the connections properly. Use a wire brush or electrical contact cleaner to remove any dirt, grease, or corrosion. This will ensure a good electrical connection and maximize the effectiveness of the dielectric grease. A guide by 3M in 2023 provides detailed instructions on proper cleaning and preparation techniques for electrical connections.

Using the Right Tools and Equipment

Using the right tools and equipment is essential for performing electrical work safely and effectively. Invest in high-quality tools that are designed for the specific tasks you’re performing. At CARDIAGTECH.BIZ, we offer a wide range of tools and equipment to meet your automotive needs.

Staying Informed and Updated

The automotive industry is constantly evolving, with new technologies and techniques being developed all the time. Stay informed and updated by attending training courses, reading industry publications, and networking with other professionals. This will help you stay ahead of the curve and provide the best possible service to your customers.

9. Addressing Customer Challenges with CARDIAGTECH.BIZ Solutions

Overcoming Physical Demands

The job of an automotive technician can be physically demanding, requiring long hours of standing, bending, and lifting. CARDIAGTECH.BIZ offers tools and equipment designed to reduce physical strain and improve comfort. Our ergonomic tools and equipment can help you work more efficiently and reduce the risk of injury.

Managing Exposure to Grease and Chemicals

Automotive technicians are constantly exposed to grease, chemicals, and other hazardous substances. CARDIAGTECH.BIZ offers a range of protective equipment to help you minimize your exposure and protect your health. Our gloves, masks, and other safety gear can help you stay safe on the job.

Keeping Up with Technology

The automotive industry is constantly evolving, with new technologies and techniques being developed all the time. CARDIAGTECH.BIZ offers a range of diagnostic tools and equipment to help you stay up-to-date with the latest technology. Our diagnostic scanners and software can help you quickly and accurately diagnose problems and perform repairs.

An automotive technician applies dielectric grease to protect and maintain electrical connections, ensuring optimal performance.

10. Frequently Asked Questions (FAQ) About Dielectric Grease

What is the primary purpose of dielectric grease?

Dielectric grease is primarily used to protect electrical connections from moisture and corrosion, ensuring reliable performance and preventing electrical failures. It acts as a sealant, lubricant, and insulator.

Can I use dielectric grease on all types of electrical connections?

Yes, dielectric grease can be used on most types of electrical connections, including battery terminals, spark plug boots, light bulb sockets, and trailer connectors. However, avoid using it on ground connections where metal-to-metal contact is essential.

How often should I reapply dielectric grease to electrical connections?

The frequency of reapplication depends on the environment and the specific application. For connections exposed to harsh conditions, such as marine environments, reapplication every year is recommended. For other applications, reapplication every few years may suffice.

What should I do if I accidentally get dielectric grease on the mating surfaces of a connector?

If you accidentally get dielectric grease on the mating surfaces of a connector, clean it off with a clean cloth or electrical contact cleaner before reassembling the connection. This ensures proper electrical contact.

Is dielectric grease harmful to the environment?

Dielectric grease is generally considered safe for the environment, but it’s important to dispose of it properly. Check your local regulations for proper disposal methods.

Can I use dielectric grease on plastic or rubber components?

Yes, dielectric grease is safe to use on plastic and rubber components. It won’t harm or degrade these materials.

What is the shelf life of dielectric grease?

The shelf life of dielectric grease is typically several years if stored properly in a cool, dry place. Check the manufacturer’s instructions for specific information.

Can I use dielectric grease on high-voltage electrical connections?

Yes, dielectric grease can be used on high-voltage electrical connections to provide insulation and protection against moisture and corrosion. However, ensure that the grease is rated for the voltage level of the connection.

Does dielectric grease affect the conductivity of electrical connections?

No, dielectric grease does not affect the conductivity of electrical connections as long as it is applied properly and not left between the mating surfaces. It is designed to insulate and protect the connection without blocking the flow of electricity.

Where can I buy high-quality dielectric grease?

You can purchase high-quality dielectric grease from automotive supply stores, hardware stores, and online retailers like CARDIAGTECH.BIZ. Ensure that you choose a reputable brand that meets your specific needs.

By following these guidelines and using high-quality products from CARDIAGTECH.BIZ, you can effectively maintain your vehicle’s electrical systems and ensure reliable performance for years to come.