How To Fix A Clear Coat On A Car: Ultimate Guide

Fixing a clear coat on a car involves addressing imperfections and restoring its glossy finish, and at CARDIAGTECH.NET, we understand the importance of this process for maintaining your vehicle’s appearance and value. Whether you’re dealing with scratches, fading, or peeling, a well-executed clear coat repair can make a significant difference. This guide provides detailed insights and practical steps to help you achieve professional-quality results. Discover how to enhance your car’s aesthetic with our comprehensive solutions. You’ll be equipped with knowledge regarding automotive detailing, paint correction, and surface preparation.

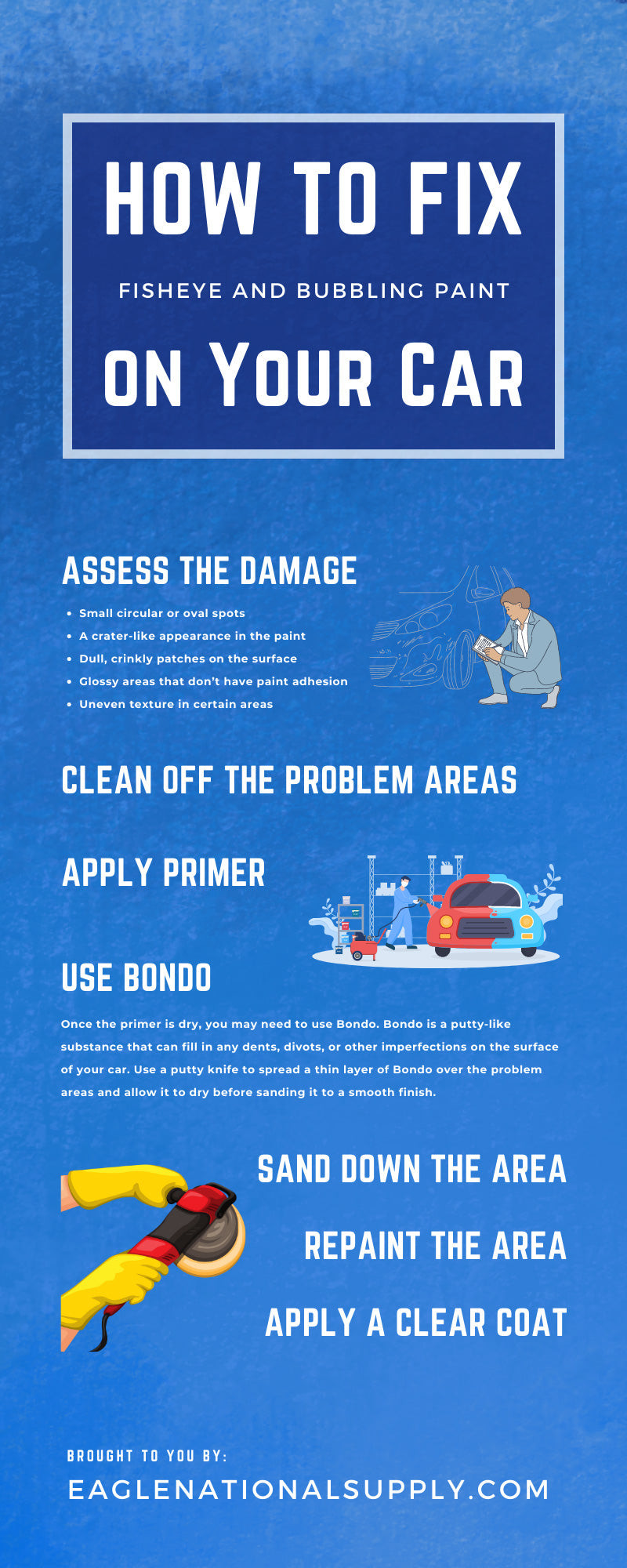

1. Understanding Clear Coat Damage

Recognizing the Types of Clear Coat Issues

Clear coat damage can manifest in several ways, each requiring a specific approach for repair. Identifying the type of damage is the first step in determining the best course of action. Common issues include scratches, swirl marks, oxidation, and peeling. Each of these problems affects the appearance and protection provided by the clear coat. Understanding the nature of the damage will guide your repair strategy.

- Scratches: These can range from minor surface imperfections to deeper gouges.

- Swirl Marks: Often caused by improper washing or polishing techniques.

- Oxidation: Results in a faded or chalky appearance.

- Peeling: Indicates severe clear coat failure, often requiring more extensive repairs.

Assessing the Severity of the Damage

The extent of the damage will dictate the repair method. Minor scratches and swirl marks can often be addressed with polishing compounds and techniques. More severe damage, such as deep scratches, oxidation, or peeling, may require sanding, priming, and re-application of the clear coat. A thorough assessment will help you determine the resources and tools needed for the job.

| Damage Type | Severity Level | Recommended Action |

|---|---|---|

| Minor Scratches | Low | Polishing compound and buffing |

| Swirl Marks | Low to Medium | Machine polishing with appropriate pads and compounds |

| Oxidation | Medium | Wet sanding followed by polishing |

| Peeling | High | Sanding down to the base coat, applying primer, and re-applying clear coat |

| Deep Scratches | High | Filling the scratch with touch-up paint, wet sanding, and polishing |

2. Essential Tools and Materials

Gathering Your Supplies

Before starting any clear coat repair, gather all the necessary tools and materials. Having everything on hand will streamline the process and ensure you achieve the best possible results. Essential supplies include:

- Sandpaper: Various grits (e.g., 400, 800, 1500, 2000, 3000)

- Polishing Compounds: Cutting, polishing, and finishing compounds

- Buffing Pads: Foam and microfiber pads

- Detailing Clay: For removing contaminants

- Masking Tape: To protect surrounding areas

- Microfiber Towels: For cleaning and polishing

- Spray Gun (Optional): For applying clear coat

- Clear Coat: Automotive-grade clear coat

- Primer: For bare metal or deep repairs

- Tack Cloth: For removing dust

- Rubbing Alcohol: For cleaning surfaces

- Water: For wet sanding

Investing in Quality Equipment

Using high-quality equipment can significantly impact the outcome of your clear coat repair. While it may be tempting to cut costs, investing in reliable tools will ensure a professional finish and prevent potential damage to your vehicle’s paint.

- Polishing Machine: A dual-action polisher is recommended for beginners as it is more forgiving and less likely to cause damage.

- Spray Gun: If you plan to apply clear coat yourself, a high-quality spray gun will provide a more even and consistent application.

- Sandpaper: Opt for automotive-grade sandpaper, which is designed for use on car paint and clear coats.

- Compounds and Pads: Use compounds and pads that are specifically designed for your polisher and the type of clear coat you are working with.

3. Preparing the Surface

Washing and Cleaning the Area

Begin by thoroughly washing the area you plan to repair. Remove any dirt, grime, and contaminants that could interfere with the repair process. Use a quality automotive soap and a soft wash mitt to avoid introducing new scratches. Rinse the area thoroughly and dry with a clean microfiber towel.

Using Detailing Clay

Detailing clay is an essential tool for removing embedded contaminants from the surface of the clear coat. These contaminants can include tree sap, bird droppings, industrial fallout, and overspray. By removing these impurities, you’ll create a smooth, clean surface for polishing or clear coat application.

- Spray the area with detailing lubricant.

- Gently rub the detailing clay over the surface in a back-and-forth motion.

- Fold the clay periodically to expose a clean surface.

- Wipe away any residue with a microfiber towel.

Masking Off Surrounding Areas

Protect any adjacent areas from accidental damage or overspray by using masking tape. Apply the tape carefully, ensuring it adheres properly to the surface. Use wide masking tape for larger areas and narrower tape for more intricate sections.

- Choose the Right Tape: Use automotive-grade masking tape that is designed to withstand the heat and chemicals involved in the repair process.

- Overlap the Tape: Overlap the tape slightly to prevent gaps and ensure full coverage.

- Press Firmly: Press the tape firmly onto the surface to create a tight seal.

4. Addressing Minor Scratches and Swirl Marks

Polishing Compounds and Techniques

For minor scratches and swirl marks, polishing compounds can be highly effective. These compounds contain abrasives that gently remove a thin layer of the clear coat, leveling out imperfections and restoring shine.

- Apply a small amount of polishing compound to a foam buffing pad.

- Work the polisher over the affected area in a back-and-forth motion, using light to moderate pressure.

- Gradually increase the speed of the polisher, maintaining consistent movement.

- Wipe away any residue with a clean microfiber towel.

- Repeat the process with a finer polishing compound and a finishing pad for a high-gloss finish.

Choosing the Right Polishing Pad

The type of polishing pad you use can significantly impact the results of your repair. Foam pads are generally used for polishing, while microfiber pads are better suited for cutting or removing more severe imperfections.

- Cutting Pads: These are the most aggressive pads and are used for removing deep scratches and swirl marks.

- Polishing Pads: These are medium-grade pads used for removing light scratches and swirl marks.

- Finishing Pads: These are the softest pads and are used for achieving a high-gloss finish.

Using a Dual-Action Polisher

A dual-action polisher is a safe and effective tool for removing scratches and swirl marks. Its oscillating motion prevents the build-up of heat, reducing the risk of damaging the clear coat.

- Attach the appropriate polishing pad to the polisher.

- Apply a small amount of polishing compound to the pad.

- Place the pad flat on the surface and turn on the polisher.

- Move the polisher in a slow, overlapping pattern, using light to moderate pressure.

- Wipe away any residue with a clean microfiber towel.

5. Repairing Deeper Scratches

Applying Touch-Up Paint

For deeper scratches that penetrate the clear coat and reach the base coat, touch-up paint can be used to fill in the damage. This will help to level the surface and provide a base for clear coat application.

- Clean the scratch thoroughly with rubbing alcohol.

- Apply a thin layer of touch-up paint to the scratch using a fine-tipped brush.

- Allow the paint to dry completely, following the manufacturer’s instructions.

- Apply additional coats as needed to fill the scratch to the level of the surrounding paint.

Wet Sanding the Touch-Up Paint

Once the touch-up paint has dried, wet sanding can be used to smooth out any imperfections and blend the repair with the surrounding clear coat.

- Soak a piece of 2000-grit sandpaper in water for several minutes.

- Wrap the sandpaper around a sanding block.

- Gently sand the touch-up paint in a back-and-forth motion, using light pressure.

- Keep the area wet to prevent the sandpaper from clogging.

- Continue sanding until the touch-up paint is level with the surrounding clear coat.

- Follow up with 3000-grit sandpaper to further refine the surface.

Polishing the Repaired Area

After wet sanding, polishing is necessary to restore the shine and clarity of the clear coat. Use a polishing compound and a foam buffing pad to remove any sanding marks and blend the repair seamlessly with the surrounding area.

- Apply a small amount of polishing compound to a foam buffing pad.

- Work the polisher over the repaired area in a back-and-forth motion, using light to moderate pressure.

- Gradually increase the speed of the polisher, maintaining consistent movement.

- Wipe away any residue with a clean microfiber towel.

- Repeat the process with a finer polishing compound and a finishing pad for a high-gloss finish.

6. Addressing Oxidation

Identifying and Evaluating Oxidation

Oxidation is a common issue that affects the clear coat, resulting in a faded or chalky appearance. It’s caused by exposure to sunlight, UV rays, and environmental pollutants. Identifying and evaluating the extent of the oxidation is crucial for determining the appropriate repair method.

- Visual Inspection: Look for a dull, faded, or chalky appearance on the clear coat.

- Touch Test: Rub your hand over the surface. If it feels rough or leaves a chalky residue on your hand, oxidation is likely present.

Wet Sanding to Remove Oxidation

Wet sanding is an effective method for removing oxidation from the clear coat. This involves using fine-grit sandpaper and water to gently remove the oxidized layer, revealing the fresh clear coat beneath.

- Soak a piece of 800-grit sandpaper in water for several minutes.

- Wrap the sandpaper around a sanding block.

- Gently sand the oxidized area in a back-and-forth motion, using light pressure.

- Keep the area wet to prevent the sandpaper from clogging.

- Continue sanding until the oxidation is removed and the surface is smooth.

- Follow up with 1500-grit and 2000-grit sandpaper to further refine the surface.

Polishing After Wet Sanding

After wet sanding, polishing is necessary to restore the shine and clarity of the clear coat. Use a polishing compound and a foam buffing pad to remove any sanding marks and blend the repair seamlessly with the surrounding area.

- Apply a small amount of polishing compound to a foam buffing pad.

- Work the polisher over the repaired area in a back-and-forth motion, using light to moderate pressure.

- Gradually increase the speed of the polisher, maintaining consistent movement.

- Wipe away any residue with a clean microfiber towel.

- Repeat the process with a finer polishing compound and a finishing pad for a high-gloss finish.

7. Repairing Peeling Clear Coat

Assessing the Extent of the Damage

Peeling clear coat is a more severe issue that requires a more extensive repair. The first step is to assess the extent of the damage to determine the best course of action. If the peeling is isolated to a small area, you may be able to spot repair it. However, if the peeling is widespread, you may need to repaint the entire panel.

Sanding Down to the Base Coat

To repair peeling clear coat, you will need to sand down to the base coat. This involves removing all of the old, peeling clear coat and creating a smooth, even surface for the new clear coat to adhere to.

- Use 400-grit sandpaper to remove the bulk of the peeling clear coat.

- Follow up with 800-grit sandpaper to smooth out the surface.

- Finish with 1500-grit sandpaper to create a very smooth surface for the new clear coat.

Applying Primer

Once you have sanded down to the base coat, you will need to apply a primer. This will help the new clear coat to adhere to the base coat and will also provide a uniform surface for the clear coat to bond to.

- Clean the sanded area with a wax and grease remover.

- Apply a thin, even coat of primer to the area.

- Allow the primer to dry completely, following the manufacturer’s instructions.

- Sand the primer with 2000-grit sandpaper to create a smooth surface.

Applying New Clear Coat

After the primer has dried and been sanded, you can apply the new clear coat. It’s important to use a high-quality automotive clear coat for the best results.

- Mix the clear coat according to the manufacturer’s instructions.

- Load the clear coat into a spray gun.

- Apply several thin, even coats of clear coat to the primed area, allowing each coat to flash (dry slightly) before applying the next.

- Allow the clear coat to dry completely, following the manufacturer’s instructions.

8. Applying New Clear Coat

Choosing the Right Clear Coat Product

Selecting the right clear coat is crucial for achieving a durable and glossy finish. There are several types of clear coats available, each with its own properties and benefits.

- Single-Stage Clear Coat: This type of clear coat is easy to apply and provides good protection, but it may not be as durable or glossy as other options.

- Two-Stage Clear Coat: This type of clear coat consists of two components, a resin and a hardener, which are mixed together before application. It offers excellent durability and gloss.

- Water-Based Clear Coat: This type of clear coat is environmentally friendly and easy to clean up, but it may not be as durable as solvent-based options.

Mixing and Preparing the Clear Coat

Proper mixing and preparation of the clear coat are essential for achieving a consistent and even finish. Follow the manufacturer’s instructions carefully, paying attention to the mixing ratios and recommended thinning agents.

- Measure the clear coat and hardener according to the manufacturer’s instructions.

- Mix the components thoroughly, using a mixing stick or a mechanical mixer.

- Add the appropriate amount of thinner, if required, to achieve the desired viscosity.

- Strain the mixture through a paint strainer to remove any contaminants.

Applying the Clear Coat in Thin, Even Layers

When applying clear coat, it’s important to use thin, even layers to avoid runs, sags, and other imperfections. Apply the clear coat in a well-ventilated area, using a spray gun or aerosol can.

- Hold the spray gun or aerosol can approximately 8-10 inches from the surface.

- Apply the clear coat in a smooth, even motion, overlapping each pass by about 50%.

- Apply two to three coats of clear coat, allowing each coat to flash (dry slightly) before applying the next.

- Allow the clear coat to dry completely, following the manufacturer’s instructions.

9. Post-Application Care

Allowing the Clear Coat to Cure Properly

After applying the clear coat, it’s important to allow it to cure properly. Curing is the process by which the clear coat hardens and reaches its full strength and durability. The curing time will vary depending on the type of clear coat used and the ambient temperature.

- Follow the Manufacturer’s Instructions: The manufacturer’s instructions will provide the recommended curing time for the specific clear coat you are using.

- Maintain Proper Temperature: The ideal curing temperature is typically between 60°F and 80°F (15°C and 27°C).

- Avoid Touching the Surface: Avoid touching the surface of the clear coat during the curing process, as this can leave fingerprints or other imperfections.

Polishing and Buffing the New Clear Coat

Once the clear coat has fully cured, you can polish and buff it to enhance the shine and remove any minor imperfections. This will give your car a showroom-quality finish.

- Apply a small amount of polishing compound to a foam buffing pad.

- Work the polisher over the clear coated area in a back-and-forth motion, using light to moderate pressure.

- Gradually increase the speed of the polisher, maintaining consistent movement.

- Wipe away any residue with a clean microfiber towel.

- Repeat the process with a finer polishing compound and a finishing pad for a high-gloss finish.

Applying Wax or Sealant for Protection

To protect your new clear coat from the elements and maintain its shine, apply a coat of wax or sealant. These products provide a barrier against UV rays, environmental pollutants, and other damaging elements.

- Choose the Right Product: Select a wax or sealant that is specifically designed for automotive clear coats.

- Apply Thinly and Evenly: Apply the wax or sealant in a thin, even layer, following the manufacturer’s instructions.

- Buff to a Shine: After the wax or sealant has dried, buff it to a high shine using a clean microfiber towel.

10. Maintaining Your Car’s Clear Coat

Regular Washing and Drying Techniques

Regular washing and drying are essential for maintaining your car’s clear coat. Wash your car at least every two weeks, or more often if it is exposed to harsh conditions.

- Use a Quality Automotive Soap: Use a pH-balanced automotive soap that is specifically designed for car paint.

- Use a Soft Wash Mitt: Use a soft wash mitt made of microfiber or sheepskin to avoid scratching the clear coat.

- Rinse Thoroughly: Rinse the car thoroughly with clean water to remove all soap residue.

- Dry with a Microfiber Towel: Dry the car with a clean, soft microfiber towel to prevent water spots.

Avoiding Harsh Chemicals and Abrasives

Harsh chemicals and abrasives can damage the clear coat, leading to fading, scratches, and other imperfections. Avoid using these products when washing or detailing your car.

- Avoid Dish Soap: Dish soap is too harsh for car paint and can strip away the wax and sealant.

- Avoid Abrasive Cleaners: Avoid using abrasive cleaners, such as scouring pads or steel wool, which can scratch the clear coat.

- Avoid Automatic Car Washes: Automatic car washes can use harsh chemicals and abrasive brushes that can damage the clear coat.

Protecting Your Car from the Elements

Protecting your car from the elements is crucial for maintaining the clear coat. Exposure to sunlight, UV rays, and environmental pollutants can cause the clear coat to fade, oxidize, and break down over time.

- Park in the Shade: Park your car in the shade whenever possible to protect it from the sun’s harmful rays.

- Use a Car Cover: Use a car cover to protect your car from the elements when it is parked outdoors.

- Apply Wax or Sealant Regularly: Apply a coat of wax or sealant every few months to provide a barrier against UV rays and environmental pollutants.

11. Common Mistakes to Avoid

Over-Sanding the Clear Coat

One of the most common mistakes when repairing clear coat is over-sanding. Sanding too aggressively or using too coarse of a grit can remove too much clear coat, leading to damage to the base coat.

- Use the Right Grit: Use the appropriate grit of sandpaper for the task at hand. Start with a fine grit and gradually increase the grit as needed.

- Use Light Pressure: Use light pressure when sanding to avoid removing too much clear coat.

- Keep the Area Wet: Keep the area wet when sanding to prevent the sandpaper from clogging and scratching the clear coat.

Applying Too Much Clear Coat

Applying too much clear coat can lead to runs, sags, and other imperfections. It’s important to apply the clear coat in thin, even layers to avoid these issues.

- Use Thin, Even Layers: Apply the clear coat in thin, even layers, allowing each coat to flash (dry slightly) before applying the next.

- Maintain Proper Distance: Hold the spray gun or aerosol can at the proper distance from the surface to avoid applying too much clear coat.

- Adjust the Spray Gun Settings: Adjust the spray gun settings to achieve the desired spray pattern and flow rate.

Neglecting Surface Preparation

Neglecting surface preparation is a common mistake that can lead to poor results. Proper surface preparation is essential for ensuring that the new clear coat adheres properly and provides a smooth, even finish.

- Wash and Clean the Area: Wash and clean the area thoroughly to remove any dirt, grime, and contaminants.

- Remove Oxidation: Remove any oxidation from the clear coat using wet sanding or a polishing compound.

- Mask Off Surrounding Areas: Mask off any surrounding areas to protect them from overspray.

Skimping on Quality Products

Skimping on quality products can lead to poor results and a less durable finish. It’s important to use high-quality automotive clear coats, polishing compounds, and other products to ensure the best possible outcome.

- Use Automotive-Grade Products: Use products that are specifically designed for automotive clear coats.

- Choose Reputable Brands: Choose products from reputable brands that are known for their quality and performance.

- Read Reviews: Read reviews from other users to get an idea of the product’s performance and durability.

12. When to Seek Professional Help

Evaluating Your Skills and Resources

While many clear coat repairs can be done at home, some situations may require professional help. Evaluate your skills and resources to determine whether you can handle the repair yourself or if it’s best to seek assistance from a professional.

- Consider the Severity of the Damage: If the damage is severe, such as widespread peeling or deep scratches, it may be best to seek professional help.

- Assess Your Skills: If you are not comfortable with sanding, polishing, or applying clear coat, it’s best to leave the repair to a professional.

- Evaluate Your Resources: If you lack the necessary tools or equipment, it may be more cost-effective to hire a professional.

Finding a Reputable Auto Body Shop

If you decide to seek professional help, it’s important to find a reputable auto body shop with experienced technicians.

- Ask for Recommendations: Ask friends, family, or colleagues for recommendations.

- Check Online Reviews: Check online reviews to get an idea of the shop’s reputation and quality of work.

- Visit the Shop: Visit the shop in person to assess its cleanliness, organization, and professionalism.

- Get a Written Estimate: Get a written estimate that includes a detailed breakdown of the costs involved.

Understanding the Costs Involved

The cost of clear coat repair can vary depending on the extent of the damage, the type of clear coat used, and the labor rates of the auto body shop. Be sure to get a clear understanding of the costs involved before authorizing any repairs.

- Get Multiple Estimates: Get estimates from several different auto body shops to compare prices.

- Ask About Warranties: Ask about warranties on the repair work and the clear coat itself.

- Consider Insurance Coverage: Check with your insurance company to see if the repair is covered under your policy.

13. The Science Behind Clear Coat

Understanding the Composition of Clear Coat

Clear coat is a transparent layer applied over the base coat of a car’s paint system. It is primarily composed of resins, solvents, and additives. The resins provide the clear coat with its durability, gloss, and resistance to chemicals and UV rays. The solvents help to dissolve the resins and allow the clear coat to be applied evenly. The additives enhance the clear coat’s properties, such as its flexibility, adhesion, and UV resistance.

- Resins: Typically polyurethane or acrylic-based, providing the main protective and aesthetic qualities.

- Solvents: Ensure the clear coat can be sprayed evenly and evaporate during the curing process.

- Additives: Include UV absorbers, stabilizers, and flow enhancers to improve performance and longevity.

The Curing Process Explained

The curing process is a chemical reaction that transforms the liquid clear coat into a solid, durable film. This process involves the cross-linking of the resin molecules, creating a strong, interconnected network. The curing process can be accelerated by heat or UV light.

- Evaporation: Solvents evaporate, leaving the resins and additives on the surface.

- Cross-Linking: Resin molecules react with hardeners, forming a strong polymer network.

- Hardening: The clear coat hardens, providing a protective layer over the base coat.

The Role of UV Protection

UV radiation is a major cause of clear coat damage. UV rays can break down the chemical bonds in the clear coat, leading to fading, oxidation, and cracking. To protect the clear coat from UV damage, manufacturers add UV absorbers to the clear coat formulation. These UV absorbers absorb the UV rays and convert them into heat, which is then dissipated.

- UV Absorbers: Chemicals that absorb UV radiation and prevent it from damaging the clear coat.

- Stabilizers: Help to prevent the breakdown of the clear coat due to UV exposure.

- Regular Maintenance: Applying wax or sealant with UV protection can further enhance the clear coat’s resistance to UV damage.

14. Advanced Techniques for Clear Coat Repair

Blending Clear Coat for Seamless Repairs

Blending clear coat is an advanced technique used to seamlessly blend a repaired area with the surrounding original clear coat. This technique involves feathering the edges of the new clear coat to create a smooth transition.

- Prepare the Surface: Sand and clean the area to be repaired, as described in previous sections.

- Apply Clear Coat: Apply the new clear coat to the repaired area, extending slightly beyond the damaged area.

- Blend the Edges: Use a blending solvent to feather the edges of the new clear coat, creating a smooth transition to the original clear coat.

- Polish and Buff: Polish and buff the blended area to remove any imperfections and enhance the shine.

Using Infrared Lamps for Faster Curing

Infrared (IR) lamps can be used to accelerate the curing process of clear coat. IR lamps emit infrared radiation, which heats the clear coat from the inside out, speeding up the cross-linking process.

- Apply Clear Coat: Apply the clear coat as described in previous sections.

- Position the IR Lamp: Position the IR lamp at the recommended distance from the clear coated area.

- Set the Timer: Set the timer on the IR lamp to the recommended curing time.

- Monitor the Temperature: Monitor the temperature of the clear coat to ensure it does not overheat.

Spot Repairing Small Areas of Damage

Spot repairing is a technique used to repair small areas of clear coat damage without having to repaint the entire panel. This technique involves carefully sanding and polishing the damaged area, then applying new clear coat to the spot.

- Clean the Area: Clean the area to be repaired with a wax and grease remover.

- Sand the Area: Sand the damaged area with fine-grit sandpaper to remove any imperfections.

- Apply Clear Coat: Apply a small amount of clear coat to the spot, feathering the edges to blend with the surrounding clear coat.

- Polish and Buff: Polish and buff the repaired area to remove any imperfections and enhance the shine.

15. DIY vs. Professional Clear Coat Repair: A Comparison

Cost Analysis

DIY clear coat repair can be more cost-effective than professional repair, especially for minor damage. However, the cost of materials, tools, and potential mistakes should be considered.

| Factor | DIY Repair | Professional Repair |

|---|---|---|

| Materials | $50 – $200 | Included in service |

| Tools | $100 – $500 (one-time) | Included in service |

| Labor | Your own time | $50 – $100 per hour |

| Potential Cost | $150 – $700 | $300 – $1500+ |

Time Investment

DIY repair requires a significant time investment, including research, preparation, repair, and cleanup. Professional repair saves time but comes at a higher cost.

- DIY Repair: Can take several hours or days, depending on the complexity of the repair.

- Professional Repair: Typically takes a few hours to a few days, depending on the shop’s schedule and the extent of the damage.

Quality of Results

Professional repair generally provides higher quality results due to the expertise, experience, and specialized equipment of the technicians. DIY repair can achieve good results with practice and attention to detail.

- DIY Repair: Results can vary depending on skill level and equipment.

- Professional Repair: Typically achieves a seamless, high-quality finish.

Risk Assessment

DIY repair carries the risk of making mistakes that can damage the clear coat or base coat. Professional repair minimizes this risk due to the expertise and experience of the technicians.

- DIY Repair: Risk of damaging the paint or achieving a poor finish.

- Professional Repair: Lower risk due to the expertise and experience of the technicians.

16. Environmental Considerations

Using Eco-Friendly Products

When repairing clear coat, it’s important to consider the environmental impact of the products you use. Opt for eco-friendly products whenever possible to reduce your carbon footprint and protect the environment.

- Water-Based Clear Coats: Water-based clear coats have lower VOC emissions than solvent-based clear coats.

- Low-VOC Solvents: Use low-VOC solvents for cleaning and degreasing.

- Recycled Materials: Choose products made from recycled materials whenever possible.

Proper Disposal of Waste Materials

Proper disposal of waste materials is essential for protecting the environment. Dispose of used sandpaper, polishing pads, and other waste materials in accordance with local regulations.

- Hazardous Waste Disposal: Dispose of hazardous waste, such as used solvents and clear coat, at a designated hazardous waste collection site.

- Recycling: Recycle used sandpaper and polishing pads whenever possible.

- Proper Storage: Store unused clear coat and solvents in a cool, dry place, away from heat and flames.

Reducing VOC Emissions

Volatile organic compounds (VOCs) are emitted during the application and curing of clear coat. VOCs can contribute to air pollution and have negative health effects. Reduce VOC emissions by using low-VOC products and following proper application techniques.

- Use Low-VOC Products: Use low-VOC clear coats and solvents whenever possible.

- Apply in a Well-Ventilated Area: Apply clear coat in a well-ventilated area to reduce the concentration of VOCs in the air.

- Use a Respirator: Wear a respirator to protect yourself from inhaling VOCs.

17. Innovations in Clear Coat Technology

Self-Healing Clear Coats

Self-healing clear coats are a revolutionary technology that allows the clear coat to repair minor scratches and swirl marks on its own. These clear coats contain polymers that can flow and fill in scratches when exposed to heat or sunlight.

- Polymer Technology: Self-healing clear coats contain polymers that can flow and fill in scratches.

- Heat Activation: The self-healing process is typically activated by heat from the sun or a heat gun.

- Enhanced Durability: Self-healing clear coats can provide enhanced durability and scratch resistance.

Ceramic Clear Coats

Ceramic clear coats are a type of clear coat that contains ceramic nanoparticles. These nanoparticles create a hard, durable layer that is highly resistant to scratches, chemicals, and UV rays.

- Nanoparticle Technology: Ceramic clear coats contain ceramic nanoparticles that create a hard, durable layer.

- Enhanced Protection: Ceramic clear coats provide enhanced protection against scratches, chemicals, and UV rays.

- Long-Lasting Shine: Ceramic clear coats can maintain their shine and gloss for years with proper maintenance.

Graphene Clear Coats

Graphene clear coats are a cutting-edge technology that incorporates graphene, a one-atom-thick layer of carbon atoms arranged in a hexagonal lattice. Graphene is incredibly strong, lightweight, and flexible, making it an ideal additive for clear coats.

- Graphene Infusion: Graphene clear coats infuse graphene into the clear coat matrix, enhancing its strength and durability.

- Superior Scratch Resistance: Graphene clear coats offer superior scratch resistance compared to traditional clear coats.

- Improved UV Protection: Graphene can help to block UV rays, protecting the underlying paint from fading and damage.

18. Legal and Regulatory Considerations

Compliance with VOC Regulations

The use of clear coats is regulated by various environmental agencies to control VOC emissions. It’s important to comply with these regulations to avoid fines and penalties.

- EPA Regulations: The Environmental Protection Agency (EPA) sets limits on VOC emissions from automotive coatings.

- State Regulations: Many states have their own VOC regulations that may be more stringent than federal regulations.

- Local Regulations: Local governments may also have VOC regulations that apply to automotive coatings.

Safety Standards and Guidelines

When repairing clear coat, it’s important to follow safety standards and guidelines to protect yourself from hazards.

- Wear Protective Gear: Wear protective gear, such as gloves, goggles, and a respirator, to protect yourself from chemicals and fumes.

- Work in a Well-Ventilated Area: Work in a well-ventilated area to reduce the concentration of VOCs in the air.

- Follow Product Instructions: Follow the manufacturer’s instructions for the safe use of clear coats and solvents.

Insurance Considerations

If your clear coat damage is caused by an accident or other covered event, your insurance company may cover the cost of repairs.

- Check Your Policy: Check your insurance policy to see if clear coat repair is covered.

- File a Claim: File a claim with your insurance company to initiate the repair process.

- Get an Estimate: Get an estimate from a reputable auto body shop to provide to your insurance company.

19. Case Studies: Successful Clear Coat Repairs

Example 1: Restoring a Faded Classic Car

Problem: A classic car had severe oxidation and fading of the clear coat due to years of exposure to the elements.

Solution:

- Preparation: The car was thoroughly washed and clayed to remove contaminants.

- Wet Sanding: The oxidized clear coat was carefully wet sanded with 800, 1500, and 2000 grit sandpaper.

- Polishing: The surface was polished with a cutting compound, followed by a polishing compound, and finally a finishing compound.

- Waxing: A high-quality wax was applied to protect the restored clear coat.

Result: The car’s clear coat was restored to its original shine, enhancing its overall appearance and value.

Example 2: Repairing Scratches on a Modern Vehicle

Problem: A modern vehicle had several deep scratches on the clear coat caused by improper washing techniques.

Solution:

- Cleaning: The area around the scratches was thoroughly