How To Fix A Car Horn: A Comprehensive Guide

Fixing a car horn involves diagnosing and resolving electrical or mechanical issues. CARDIAGTECH.NET provides tools and diagnostic equipment to simplify this process, ensuring your car horn blares loud and clear. This guide covers troubleshooting common problems and using professional equipment for effective car horn maintenance.

1. Understanding the Importance of a Functional Car Horn

A working car horn is essential for safety, enabling drivers to alert others. It’s not just about avoiding accidents, but also about compliance with safety regulations. The National Highway Traffic Safety Administration (NHTSA) emphasizes the importance of audible warnings in preventing collisions. Regular maintenance, including checking the horn, is crucial for vehicle safety.

A car horn serves several critical functions:

- Alerting Pedestrians: Warn pedestrians of your vehicle’s presence, especially in areas with limited visibility.

- Signaling Other Drivers: Communicate intentions, such as signaling to pass or warning of potential hazards.

- Emergency Situations: Attract attention in case of accidents or breakdowns.

- Legal Compliance: Many jurisdictions require a functioning horn for vehicle inspections and roadworthiness.

2. Identifying the Symptoms of a Malfunctioning Car Horn

Recognizing the symptoms of a malfunctioning car horn can save time and prevent further damage. Common symptoms include:

- No Sound: The horn produces no sound when the horn button is pressed.

- Weak or Muffled Sound: The horn sounds weak, distorted, or muffled.

- Intermittent Sound: The horn works sometimes but not consistently.

- Clicking Sound: A clicking noise from the horn area when the horn button is pressed, but no horn sound.

- Constant Sound: The horn sounds continuously without pressing the horn button.

If you experience any of these symptoms, it’s time to troubleshoot your car horn. CARDIAGTECH.NET offers diagnostic tools that can help you quickly identify the root cause of the problem.

3. Essential Tools and Equipment for Car Horn Repair

Having the right tools can make car horn repair efficient. Here’s a list of essential tools and equipment:

- Multimeter: For testing voltage and continuity in the electrical circuit.

- Test Light: To check for power at various points in the circuit.

- Socket Set: To remove and install the horn and related components.

- Screwdrivers: Both Phillips head and flathead screwdrivers for various fasteners.

- Wire Strippers/Crimpers: For repairing or replacing wiring.

- Pliers: For gripping and manipulating wires and connectors.

- Fuses: Replacement fuses of the correct amperage.

- Relay Tester: To test the horn relay.

- Jumper Wire: For bypassing components to isolate the problem.

- Contact Cleaner: To clean electrical connections.

- WD-40: To loosen corroded parts.

Investing in quality tools from CARDIAGTECH.NET ensures durability and precision, reducing the risk of damaging your vehicle during repairs.

4. Step-by-Step Guide to Diagnosing a Car Horn Problem

Diagnosing a car horn problem involves a systematic approach. Here’s a detailed guide:

4.1. Initial Inspection

- Check the Horn Location: Car horns are typically located behind the front grille or under the hood. Refer to your vehicle’s manual for the exact location.

- Visual Inspection: Look for obvious signs of damage, such as corrosion, loose connections, or broken wires.

- Clean Connections: Clean any visible corrosion from the horn terminals using a wire brush and contact cleaner.

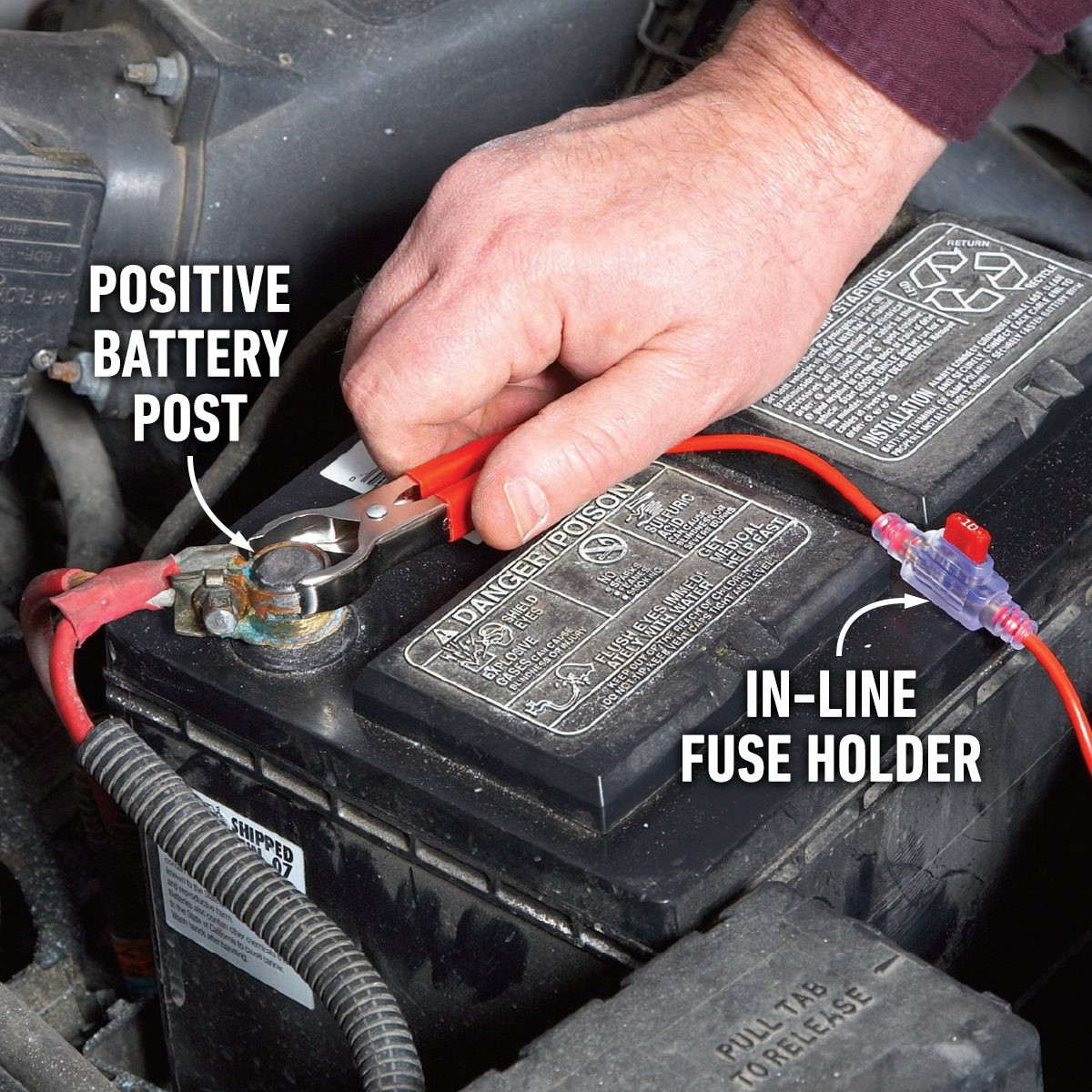

4.2. Check the Fuse

- Locate the Fuse Box: The fuse box is usually under the dashboard or in the engine compartment.

- Identify the Horn Fuse: Consult your owner’s manual to find the fuse labeled for the horn.

- Inspect the Fuse: Remove the fuse and check if the filament is broken. If it is, the fuse is blown.

- Replace the Fuse: Replace the blown fuse with a new fuse of the same amperage.

- Test the Horn: Try the horn again. If it works, the problem is solved. If the fuse blows again, there’s a short circuit in the system.

Checking the fuse for a car horn

Checking the fuse for a car horn

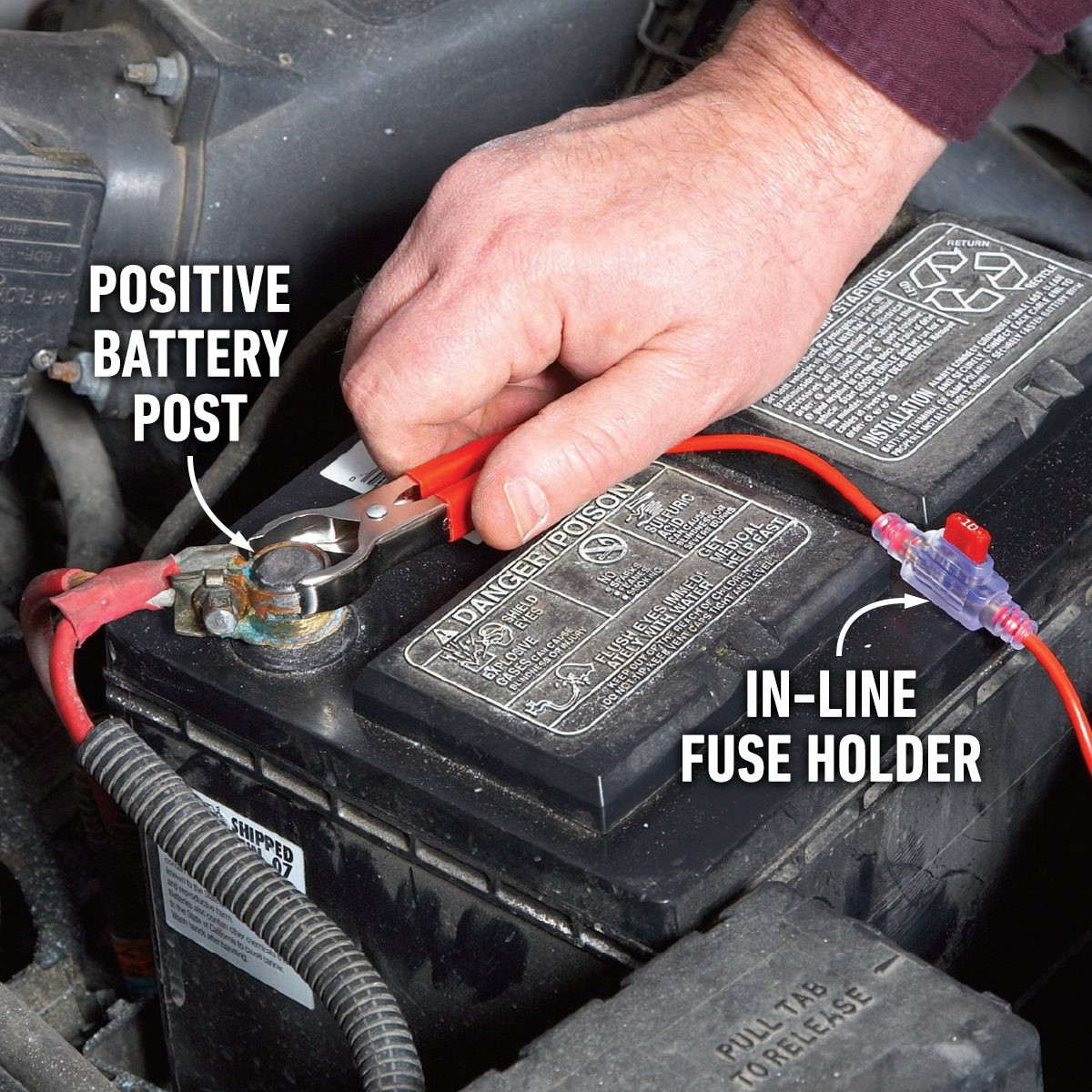

4.3. Test the Horn Relay

- Locate the Relay: Find the horn relay in the fuse box. Your owner’s manual will have the exact location.

- Swap the Relay: Swap the horn relay with another relay of the same type (e.g., the relay for the headlights or windshield wipers).

- Test the Horn: If the horn works with the swapped relay, the original relay is faulty and needs replacement.

- Relay Tester: Use a relay tester from CARDIAGTECH.NET for a more accurate assessment of the relay’s functionality.

4.4. Check the Horn Switch

- Access the Horn Switch: The horn switch is usually located in the steering wheel. This might require removing the airbag, so disconnect the battery first to prevent accidental deployment.

- Test for Continuity: Use a multimeter to check for continuity when the horn button is pressed. If there’s no continuity, the switch is faulty.

- Professional Assistance: If you’re not comfortable working with the airbag, take your vehicle to a professional.

4.5. Inspect Wiring and Connections

- Visual Inspection: Check all the wiring connected to the horn, relay, and switch for any signs of damage, such as cuts, breaks, or corrosion.

- Test for Voltage: Use a multimeter to check for voltage at the horn connector when the horn button is pressed. If there’s no voltage, there’s a break in the wiring.

- Check the Ground Connection: Ensure the horn has a good ground connection. Clean the ground connection point to remove any corrosion.

4.6. Direct Power Test

- Disconnect the Horn: Disconnect the horn from its wiring harness.

- Apply Direct Power: Use a jumper wire to connect the horn directly to the battery.

- Observe the Result: If the horn works, the problem is in the wiring, relay, or switch. If it doesn’t, the horn itself is faulty.

By following these steps, you can systematically diagnose and pinpoint the car horn problem, making the repair process more efficient.

5. Detailed Steps to Fix a Car Horn

Once you’ve diagnosed the problem, you can proceed with the repair. Here are detailed steps for common car horn issues:

5.1. Replacing a Blown Fuse

- Locate the Fuse Box: Find the fuse box, usually under the dashboard or in the engine compartment.

- Identify the Horn Fuse: Refer to your owner’s manual for the correct fuse location.

- Remove the Blown Fuse: Use a fuse puller to remove the blown fuse.

- Install a New Fuse: Insert a new fuse of the same amperage into the slot.

- Test the Horn: Turn on the ignition and test the horn.

5.2. Replacing a Faulty Relay

- Locate the Relay: Find the horn relay in the fuse box.

- Remove the Old Relay: Pull out the faulty relay.

- Install a New Relay: Insert a new relay of the same type into the slot.

- Test the Horn: Turn on the ignition and test the horn.

5.3. Repairing or Replacing Wiring

- Identify Damaged Wiring: Locate any damaged sections of wiring.

- Cut and Strip Wires: Cut out the damaged section and strip the ends of the wires.

- Join the Wires: Use a wire connector or solder to join the wires.

- Insulate the Connection: Wrap the connection with electrical tape.

- Replace the Wiring: If the wiring is severely damaged, replace the entire wire.

5.4. Replacing a Faulty Horn Switch

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent accidental airbag deployment.

- Remove the Airbag: Carefully remove the airbag from the steering wheel. This might require special tools.

- Access the Horn Switch: Locate the horn switch behind the airbag.

- Disconnect the Switch: Disconnect the wiring from the faulty switch.

- Install a New Switch: Connect the wiring to the new switch.

- Reinstall the Airbag: Carefully reinstall the airbag.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Test the Horn: Turn on the ignition and test the horn.

5.5. Replacing a Faulty Car Horn

- Locate the Horn: Find the horn behind the front grille or under the hood.

- Disconnect the Wiring: Disconnect the wiring from the horn.

- Remove the Horn: Remove the bolts or screws holding the horn in place.

- Install a New Horn: Install the new horn and secure it with bolts or screws.

- Reconnect the Wiring: Reconnect the wiring to the new horn.

- Test the Horn: Turn on the ignition and test the horn.

Checking the relay for a car horn

Checking the relay for a car horn

6. Advanced Troubleshooting Techniques

For more complex car horn issues, advanced troubleshooting techniques may be necessary. These techniques require a deeper understanding of automotive electrical systems and specialized tools.

6.1. Using a Multimeter

A multimeter is essential for diagnosing electrical problems. Here’s how to use it:

-

Voltage Testing:

- Set the multimeter to the voltage setting.

- Connect the black lead to a good ground.

- Probe the wire you want to test with the red lead.

- Read the voltage on the multimeter display.

-

Continuity Testing:

- Set the multimeter to the continuity setting.

- Touch the two leads together. The multimeter should beep, indicating continuity.

- Touch the leads to the two ends of the wire or component you want to test. If the multimeter beeps, there’s continuity. If it doesn’t, there’s a break in the circuit.

6.2. Using a Test Light

A test light can quickly check for power in a circuit. Here’s how to use it:

- Connect the Clip: Connect the clip of the test light to a good ground.

- Probe the Wire: Probe the wire you want to test with the probe of the test light.

- Observe the Light: If the test light illuminates, there’s power in the circuit. If it doesn’t, there’s no power.

6.3. Checking the Clock Spring

The clock spring is a spiral-wound ribbon cable that allows the steering wheel to turn while maintaining electrical connections to the airbag, horn, and other components. A faulty clock spring can cause the horn to stop working.

-

Symptoms of a Faulty Clock Spring:

- Horn not working

- Airbag warning light on

- Steering wheel controls not working

-

Testing the Clock Spring:

- Disconnect the battery.

- Remove the airbag.

- Use a multimeter to check for continuity through the clock spring.

- If there’s no continuity, the clock spring needs to be replaced.

6.4. Diagnosing Grounding Issues

A poor ground connection can cause the horn to work intermittently or not at all.

-

Symptoms of Grounding Issues:

- Horn works intermittently

- Weak horn sound

- Clicking sound but no horn

-

Testing for Grounding Issues:

- Use a multimeter to check for continuity between the horn’s ground wire and the vehicle’s chassis.

- Clean the ground connection point to remove any corrosion.

- Add an additional ground wire from the horn to the chassis to improve the ground connection.

7. Common Causes of Car Horn Failure

Understanding the common causes of car horn failure can help you diagnose and prevent problems:

- Corrosion: Corrosion on the horn terminals or wiring can prevent the horn from working.

- Blown Fuse: A blown fuse is one of the most common causes of car horn failure.

- Faulty Relay: A faulty relay can prevent power from reaching the horn.

- Damaged Wiring: Damaged or broken wiring can interrupt the circuit.

- Faulty Horn Switch: A faulty switch in the steering wheel can prevent the horn from working.

- Clock Spring Issues: Problems with the clock spring can affect the horn, airbag, and other steering wheel components.

- Horn Failure: The horn itself can fail due to age or damage.

8. Preventive Maintenance Tips for Car Horns

Preventive maintenance can extend the life of your car horn and prevent unexpected failures:

- Regular Inspection: Periodically inspect the horn and its wiring for any signs of damage or corrosion.

- Cleaning Connections: Clean the horn terminals and wiring connections regularly to remove corrosion.

- Protecting the Horn: Consider installing a shield to protect the horn from water and debris.

- Testing the Horn: Test the horn regularly to ensure it’s working properly.

- Replacing Components: Replace any worn or damaged components, such as fuses, relays, and wiring, promptly.

9. Upgrading Your Car Horn for Enhanced Performance

If you’re looking for a louder or more distinctive horn, consider upgrading to an aftermarket car horn. CARDIAGTECH.NET offers a variety of high-quality car horns that can enhance your vehicle’s safety and presence.

9.1. Types of Aftermarket Car Horns

- Air Horns: Air horns are very loud and produce a powerful sound.

- Electric Horns: Electric horns are more compact and easier to install than air horns.

- Musical Horns: Musical horns play a tune instead of a standard horn sound.

9.2. Factors to Consider When Upgrading

- Sound Level: Choose a horn that’s loud enough to be heard in traffic.

- Sound Quality: Select a horn with a sound that you find pleasing.

- Ease of Installation: Consider how easy the horn is to install.

- Durability: Look for a horn that’s built to last.

- Legal Compliance: Make sure the horn complies with local noise regulations.

9.3. Installation Tips for Aftermarket Horns

- Read the Instructions: Follow the manufacturer’s instructions carefully.

- Disconnect the Battery: Disconnect the battery before starting the installation.

- Mount the Horn: Mount the horn securely in a location where it won’t be exposed to water and debris.

- Connect the Wiring: Connect the wiring according to the instructions.

- Test the Horn: Test the horn to make sure it’s working properly.

10. The Role of CARDIAGTECH.NET in Car Horn Maintenance

CARDIAGTECH.NET is committed to providing high-quality tools and equipment for car maintenance. Our diagnostic tools, multimeters, relay testers, and other products are designed to make car horn repair efficient and effective. With CARDIAGTECH.NET, you can ensure your car horn is always in top condition.

11. Real-World Examples of Car Horn Repairs

Here are a few real-world examples of car horn repairs:

- Case 1: Blown Fuse: A customer complained that their car horn wasn’t working. After checking the fuse box, we found a blown fuse. Replacing the fuse solved the problem.

- Case 2: Corroded Connections: Another customer reported a weak horn sound. Upon inspection, we found corroded connections at the horn terminals. Cleaning the connections restored the horn’s sound.

- Case 3: Faulty Relay: A customer experienced intermittent horn function. Testing the relay revealed it was faulty. Replacing the relay fixed the issue.

- Case 4: Damaged Wiring: A customer had no horn sound. Visual inspection revealed damaged wiring near the horn. Repairing the wiring restored the horn’s function.

12. How to Choose the Right Car Horn for Your Needs

Choosing the right car horn depends on several factors, including your budget, desired sound level, and ease of installation.

12.1. Budget Considerations

Car horns range in price from affordable replacements to high-end aftermarket options. Determine your budget before shopping.

12.2. Sound Level and Quality

Consider the sound level you need. A louder horn may be necessary if you drive in heavy traffic. Also, think about the sound quality. Do you prefer a traditional horn sound or something more distinctive?

12.3. Ease of Installation

If you plan to install the horn yourself, choose a model that’s easy to install. Look for horns that come with clear instructions and all the necessary hardware.

12.4. Compatibility

Ensure the horn is compatible with your vehicle. Check the voltage and wiring requirements to avoid compatibility issues.

13. Safety Precautions When Working with Car Electrical Systems

Working with car electrical systems can be dangerous if proper safety precautions are not taken.

- Disconnect the Battery: Always disconnect the negative terminal of the battery before working on electrical components.

- Use Insulated Tools: Use tools with insulated handles to prevent electric shock.

- Avoid Water: Never work on electrical systems in wet conditions.

- Follow Instructions: Follow the manufacturer’s instructions carefully.

- Seek Professional Help: If you’re not comfortable working on electrical systems, seek professional help.

14. Understanding Car Horn Legal Requirements and Regulations

Car horns are subject to legal requirements and regulations. Make sure your horn complies with local laws.

- Sound Level Limits: Many jurisdictions have sound level limits for car horns.

- Prohibited Sounds: Some jurisdictions prohibit the use of certain horn sounds, such as musical horns.

- Proper Use: Car horns should only be used for alerting others to potential hazards, not for expressing anger or frustration.

15. The Future of Car Horn Technology

Car horn technology is evolving, with new features and innovations on the horizon.

- Smart Horns: Smart horns use sensors to detect pedestrians and other vehicles and adjust the sound level accordingly.

- Digital Horns: Digital horns allow drivers to select different horn sounds.

- Emergency Alerts: Some car horns can send emergency alerts to other vehicles and emergency services.

16. The Benefits of Professional Car Horn Repair Services

While many car horn problems can be fixed with DIY methods, professional car horn repair services offer several benefits.

- Expertise: Professional mechanics have the expertise to diagnose and repair complex car horn problems.

- Specialized Tools: Professional shops have specialized tools and equipment for car horn repair.

- Warranty: Professional repair services often come with a warranty.

- Time Savings: Professional services can save you time and effort.

17. Maintaining Car Horn Sound Quality Over Time

Maintaining car horn sound quality involves regular checks and maintenance.

- Clean the Horn: Clean the horn regularly to remove dirt and debris.

- Check Connections: Check the wiring connections to ensure they’re secure and free from corrosion.

- Replace Worn Components: Replace any worn or damaged components, such as fuses and relays, promptly.

- Test the Horn: Test the horn regularly to ensure it’s working properly.

18. Troubleshooting Common Car Horn Noises

Different car horn noises can indicate different problems.

- No Sound: No sound usually indicates a blown fuse, faulty relay, or damaged wiring.

- Weak Sound: A weak sound can be caused by corroded connections or a faulty horn.

- Intermittent Sound: Intermittent sound can be caused by a loose connection or a faulty relay.

- Clicking Sound: A clicking sound can indicate a faulty relay or a poor ground connection.

- Constant Sound: A constant sound can be caused by a faulty horn switch or a short circuit.

19. Advanced Car Horn Customization Options

For car enthusiasts, advanced car horn customization options can add a unique touch to their vehicles.

- Air Horn Kits: Air horn kits include everything you need to install an air horn in your vehicle.

- Musical Horns: Musical horns play a tune instead of a standard horn sound.

- Train Horns: Train horns are extremely loud and produce a sound similar to a train horn.

- Custom Horn Covers: Custom horn covers can add a stylish touch to your car horn.

20. Car Horn Replacement vs. Repair: Which is Right for You?

Deciding whether to replace or repair a car horn depends on the nature and extent of the problem.

- Repair: Repair is usually the best option for minor problems, such as a blown fuse, corroded connections, or a faulty relay.

- Replace: Replacement is necessary when the horn itself is faulty or when the repair costs exceed the cost of a new horn.

When deciding whether to repair or replace, consider the following factors:

- Cost: Compare the cost of repair versus replacement.

- Time: Consider the time required for each option.

- Expertise: Assess your own expertise and comfort level.

21. The Environmental Impact of Car Horn Maintenance

Car horn maintenance can have an environmental impact. Properly disposing of old components, such as fuses, relays, and horns, is essential.

- Recycling: Recycle old components whenever possible.

- Proper Disposal: Dispose of hazardous materials, such as batteries and chemicals, properly.

- Eco-Friendly Products: Use eco-friendly products, such as biodegradable contact cleaner.

22. How to Find a Reliable Car Horn Repair Service

Finding a reliable car horn repair service is crucial for ensuring quality repairs.

- Ask for Recommendations: Ask friends, family, and colleagues for recommendations.

- Check Online Reviews: Check online reviews to see what other customers have to say.

- Look for Certifications: Look for repair shops that are certified by reputable organizations.

- Get Estimates: Get estimates from several repair shops before making a decision.

- Ask Questions: Ask questions about the repair process, warranty, and cost.

23. DIY Car Horn Repair vs. Hiring a Professional: Making the Right Choice

Deciding whether to attempt a DIY car horn repair or hire a professional depends on your skills, experience, and comfort level.

23.1. DIY Repair

- Pros:

- Cost savings

- Convenience

- Learning experience

- Cons:

- Time commitment

- Potential for mistakes

- Lack of warranty

23.2. Hiring a Professional

- Pros:

- Expertise

- Specialized tools

- Warranty

- Cons:

- Higher cost

- Inconvenience

Consider the following factors when making your decision:

- Complexity of the Repair: If the repair is complex, hiring a professional is the best option.

- Your Skills and Experience: If you have the skills and experience, you may be able to do the repair yourself.

- Your Comfort Level: If you’re not comfortable working on car electrical systems, hire a professional.

24. Frequently Asked Questions (FAQs) About Car Horns

Here are some frequently asked questions about car horns:

-

Why is my car horn not working?

- Common causes include a blown fuse, faulty relay, damaged wiring, or a faulty horn switch.

-

How do I check if my car horn fuse is blown?

- Locate the fuse box, identify the horn fuse, and inspect the filament. If the filament is broken, the fuse is blown.

-

Can I replace a car horn myself?

- Yes, if you have basic mechanical skills and the right tools.

-

How much does it cost to replace a car horn?

- The cost varies depending on the type of horn and the labor charges, but typically ranges from $50 to $200.

-

What is a car horn relay?

- A relay is an electrical switch that controls the flow of electricity to the horn.

-

How do I test a car horn relay?

- You can test a relay by swapping it with another relay of the same type or by using a relay tester.

-

What is a clock spring in a car?

- The clock spring is a spiral-wound ribbon cable that allows the steering wheel to turn while maintaining electrical connections to the airbag, horn, and other components.

-

How do I know if my car has a grounding issue?

- Symptoms of a grounding issue include intermittent horn function, a weak horn sound, or a clicking sound but no horn.

-

Can I upgrade my car horn to a louder one?

- Yes, you can upgrade to an aftermarket car horn for enhanced performance.

-

What are the legal requirements for car horns?

- Car horns are subject to sound level limits and proper use regulations.

25. CARDIAGTECH.NET: Your Partner in Automotive Excellence

At CARDIAGTECH.NET, we understand the importance of a properly functioning car horn. That’s why we offer a wide range of diagnostic tools and equipment to help you keep your vehicle in top condition. Whether you’re a professional mechanic or a DIY enthusiast, we have the tools you need to diagnose and repair car horn problems quickly and efficiently.

We encourage you to visit our website at CARDIAGTECH.NET or contact us via WhatsApp at +1 (641) 206-8880 or visit our physical location at 276 Reock St, City of Orange, NJ 07050, United States. Our knowledgeable staff is ready to answer your questions and provide expert advice. Don’t let a faulty car horn compromise your safety.

26. Call to Action

Is your car horn not working? Do you need high-quality diagnostic tools and equipment to fix it? Contact CARDIAGTECH.NET today for expert advice and assistance. Our team can help you diagnose the problem and find the right tools to get the job done. Whether you’re a professional mechanic or a DIY enthusiast, we have the solutions you need.

Don’t wait until it’s too late. Ensure your vehicle is safe and compliant with a properly functioning car horn. Contact us now for a consultation and let CARDIAGTECH.NET be your partner in automotive excellence. Reach out today and let us help you ensure your vehicle is safe and compliant with the latest standards.