**How to Interpret the Meaning of OBD-II Fault Codes?**

Deciphering OBD-II fault codes is crucial for diagnosing car issues and ensuring optimal performance, and at CARDIAGTECH.NET, we empower you with the knowledge and tools to understand these codes effectively, keeping your vehicle running smoothly and preventing costly repairs. Understanding these codes enables proactive maintenance and can significantly extend the life of your vehicle. Explore further to demystify diagnostic trouble codes, emission control, and engine performance.

1. What Exactly Are OBD-II Fault Codes?

OBD-II fault codes are alphanumeric codes generated by your vehicle’s onboard computer to signal detected issues within its systems. Think of them as your car’s way of communicating problems, from minor hiccups to significant malfunctions. According to the Society of Automotive Engineers (SAE), these codes are standardized across most vehicles manufactured after 1996, ensuring a consistent diagnostic approach.

When a sensor detects an issue—be it in the engine, transmission, or emission system—it sends a signal to the onboard computer, which then registers a corresponding code. These codes aren’t just random; they follow a specific format that helps identify the nature and location of the problem. For example, a “Check Engine” light often indicates that something isn’t performing as expected.

Here’s a quick breakdown of why understanding OBD-II codes is essential:

- Early Detection: Identify problems early, preventing them from escalating into costly repairs.

- Informed Decisions: Make informed decisions about vehicle maintenance and repairs.

- Cost Savings: Save money by diagnosing and fixing minor issues before they become major.

Want to learn more about how OBD-II scanners can help you? Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States or via WhatsApp at +1 (641) 206-8880.

2. What Are the Main Types of OBD-II Codes?

OBD-II codes are categorized into four main types, each corresponding to a different area of your vehicle. Knowing these categories can help you quickly narrow down the source of the problem.

2.1 Powertrain Codes

Powertrain codes (indicated by the letter “P”) relate to issues within the engine, transmission, and drivetrain components. These are critical for maintaining your vehicle’s power and performance.

For example, the code P0300 indicates a random or multiple cylinder misfire. According to a study by the National Institute for Automotive Service Excellence (ASE), misfires can lead to decreased fuel efficiency and potential engine damage.

Engine misfire

Engine misfire

Common Powertrain Codes and Their Meanings:

| Code | Description | Possible Causes |

|---|---|---|

| P0300 | Random/Multiple Cylinder Misfire Detected | Faulty spark plugs, vacuum leaks, fuel injector issues |

| P0171 | System Too Lean (Bank 1) | Vacuum leak, faulty oxygen sensor, low fuel pressure |

| P0301 | Cylinder 1 Misfire Detected | Faulty spark plug, ignition coil issue, fuel injector problem |

| P0420 | Catalyst System Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, oxygen sensor issues |

| P0700 | Transmission Control System Malfunction | Faulty transmission control module (TCM), solenoid issues, fluid level problems |

2.2 Body Codes

Body codes (indicated by the letter “B”) identify problems within the vehicle’s body systems, such as lighting, airbags, and climate control. These codes often relate to comfort and safety features.

For instance, the code B1000 indicates an issue with the airbag system. The National Highway Traffic Safety Administration (NHTSA) emphasizes the importance of functioning airbags for occupant safety during collisions.

Common Body Codes and Their Meanings:

| Code | Description | Possible Causes |

|---|---|---|

| B1000 | ECU Internal Failure | Faulty ECU, wiring issues, sensor malfunctions |

| B1001 | System Programming Failure | Programming error, incompatible software, corrupted data |

| B1002 | EEPROM Failure | Faulty EEPROM, data corruption, memory issues |

| B1004 | System Voltage High | Overcharging, voltage regulator issues, wiring problems |

| B1005 | System Voltage Low | Battery issues, alternator problems, wiring faults |

| B1006 | Key Not Programmed | Unprogrammed key, immobilizer issues, key recognition problems |

| B1007 | Transponder Not Programmed | Transponder failure, programming error, communication issues |

2.3 Chassis Codes

Chassis codes (indicated by the letter “C”) relate to issues within the vehicle’s chassis and related systems, including suspension, steering, and brakes. These codes are crucial for vehicle stability and handling.

For example, the code C0035 indicates a problem with the front right wheel speed sensor. A malfunctioning wheel speed sensor can affect the anti-lock braking system (ABS) and electronic stability control (ESC), according to a study by the Insurance Institute for Highway Safety (IIHS).

Common Chassis Codes and Their Meanings:

| Code | Description | Possible Causes |

|---|---|---|

| C0031 | Left Front Wheel Speed Sensor Circuit | Faulty sensor, wiring issues, damaged sensor ring |

| C0034 | Right Front Wheel Speed Sensor Circuit | Faulty sensor, wiring issues, damaged sensor ring |

| C0040 | Left Rear Wheel Speed Sensor Circuit | Faulty sensor, wiring issues, damaged sensor ring |

| C0045 | Right Rear Wheel Speed Sensor Circuit | Faulty sensor, wiring issues, damaged sensor ring |

| C0051 | Steering Angle Sensor Circuit | Faulty sensor, wiring issues, alignment problems |

| C0054 | Brake Pressure Sensor Circuit | Faulty sensor, wiring issues, hydraulic system problems |

| C0061 | ABS Solenoid Valve Control Circuit | Faulty solenoid valve, wiring issues, hydraulic system problems |

| C0062 | Traction Control System Control Circuit | Faulty TCS module, wiring issues, sensor problems |

| C0071 | Electronic Stability Control System Control Circuit | Faulty ESC module, wiring issues, sensor problems |

2.4 Network Communication Codes

Network communication codes (indicated by the letter “U”) identify problems within the vehicle’s communication systems, including modules and sensors that exchange information. These codes can indicate issues with the Controller Area Network (CAN) bus system.

For instance, the code U0100 indicates a loss of communication with the Engine Control Module (ECM). According to Bosch, a leading automotive component manufacturer, communication issues can lead to a variety of performance problems.

Common Network Communication Codes and Their Meanings:

| Code | Description | Possible Causes |

|---|---|---|

| U0001 | High Speed CAN Communication Bus | Wiring issues, faulty modules, bus problems |

| U0100 | Lost Communication With ECM/PCM | Wiring issues, faulty ECM/PCM, communication problems |

| U0101 | Lost Communication With TCM | Wiring issues, faulty TCM, communication problems |

| U0121 | Lost Communication With ABS | Wiring issues, faulty ABS module, communication problems |

| U0140 | Lost Communication With Body Control Module | Wiring issues, faulty BCM, communication problems |

| U0155 | Lost Communication With Instrument Panel Cluster | Wiring issues, faulty IPC, communication problems |

| U0401 | Invalid Data Received From ECM/PCM | Data corruption, ECM/PCM issues, communication problems |

| U0415 | Invalid Data Received From ABS | Data corruption, ABS module issues, communication problems |

Understanding these code types helps you narrow down the problem area. If you need help interpreting a specific code, CARDIAGTECH.NET is here to assist. Contact us at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880 for expert guidance.

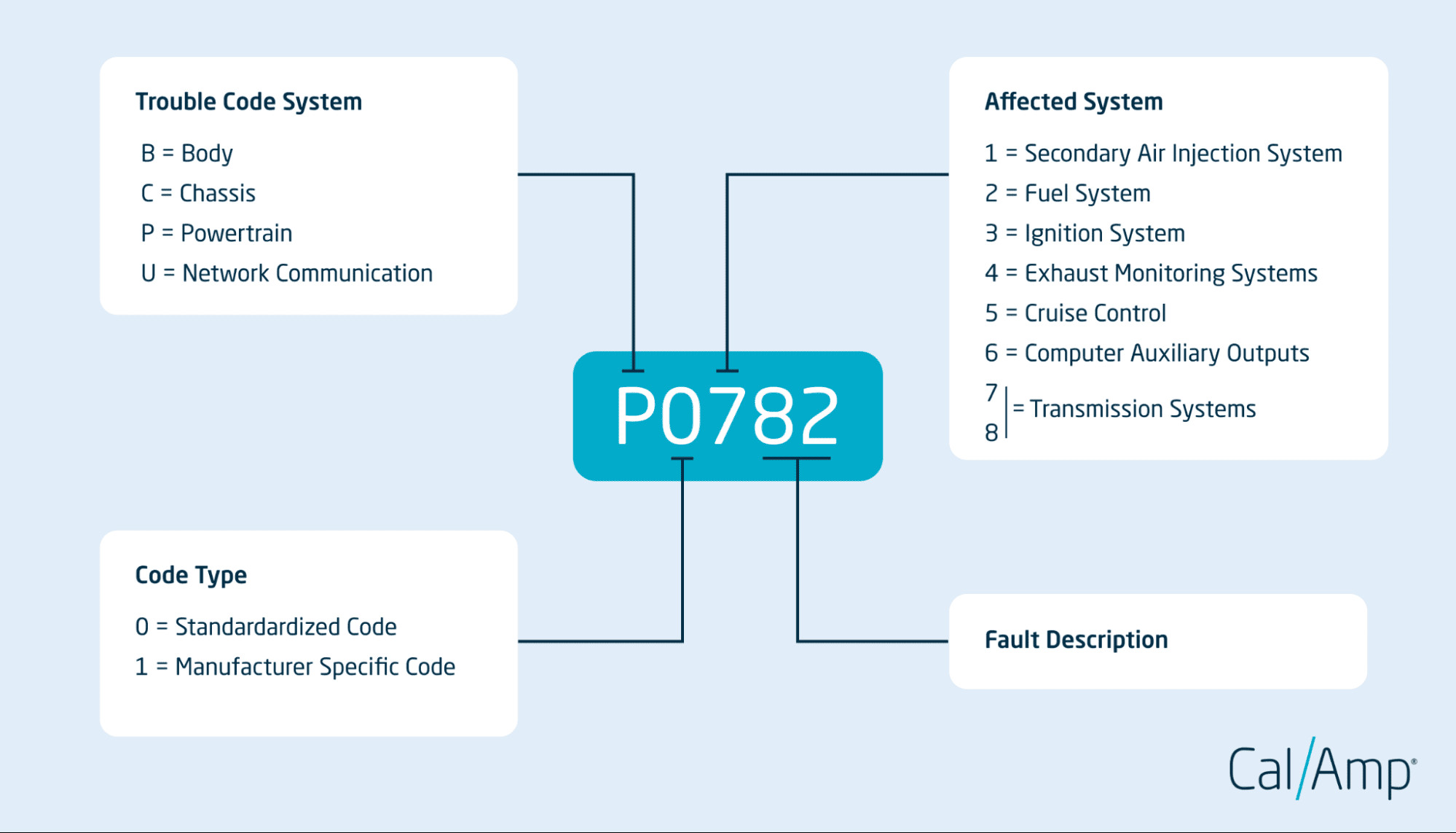

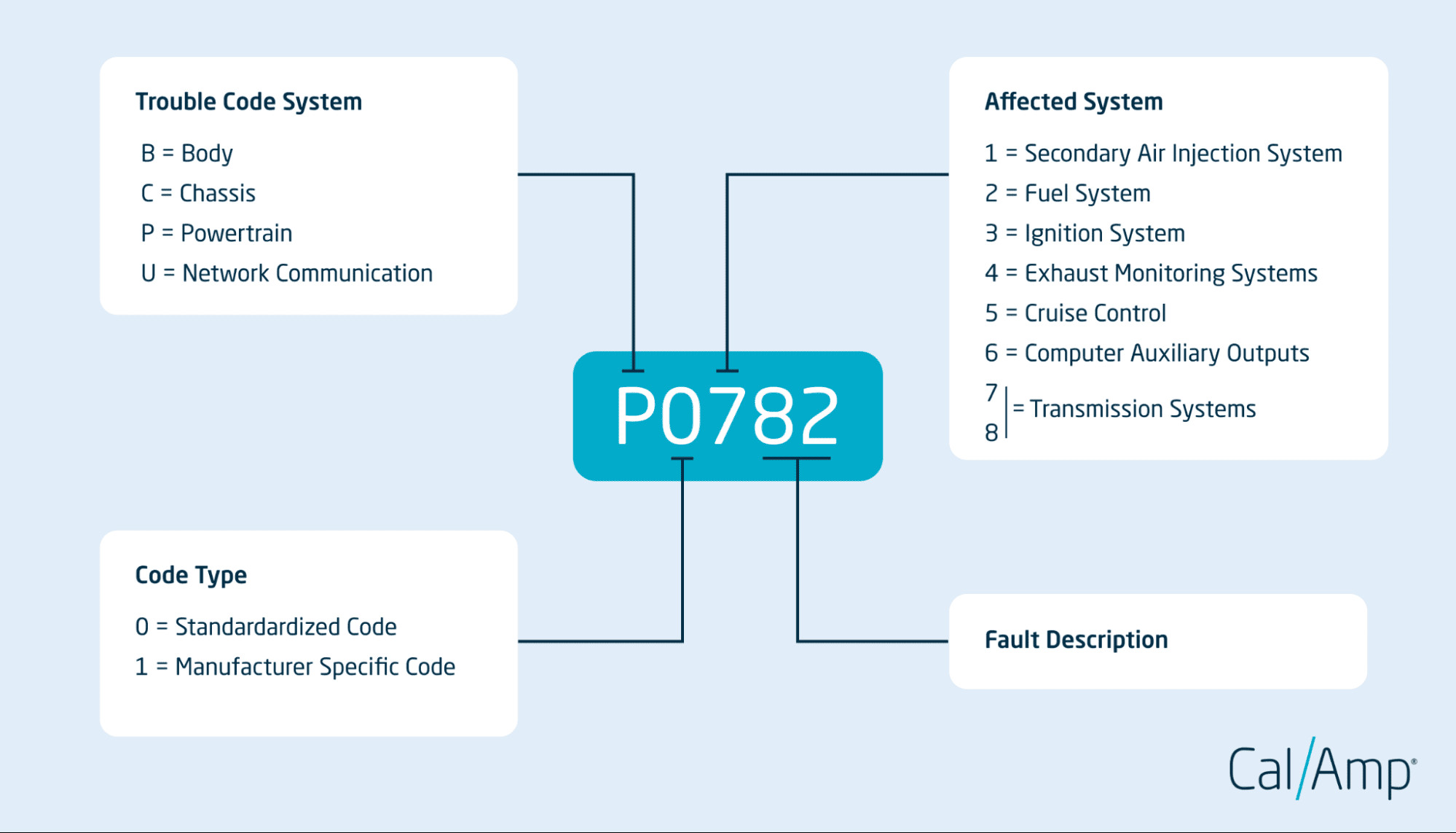

3. How to Read and Decipher OBD-II Codes?

OBD-II codes are structured in a specific way. Each of the five characters—one letter followed by four digits—provides valuable information.

3.1 Understanding the Trouble Code System

The first character of an OBD-II code indicates the system where the fault occurred.

- P: Powertrain (engine, transmission, etc.)

- B: Body (airbags, lighting, etc.)

- C: Chassis (brakes, steering, suspension, etc.)

- U: Network Communication (communication between modules)

For example, if a code starts with “P,” you know the issue is related to the powertrain.

3.2 Identifying the Code Type

The second character (a digit) indicates whether the code is standardized or manufacturer-specific.

- 0: Standardized (Generic) Code

- 1: Manufacturer-Specific Code

Standardized codes are the same across all vehicles, while manufacturer-specific codes provide more detailed information unique to the carmaker.

3.3 Determining the Affected System

The third character (a digit) indicates the specific subsystem affected.

- 0: Fuel and Air Metering

- 1: Fuel and Air Metering (Injector Circuit)

- 2: Fuel and Air Metering (Fuel Pump)

- 3: Ignition System or Misfire

- 4: Auxiliary Emission Controls

- 5: Vehicle Speed Controls and Idle Control System

- 6: Computer Output Circuit

- 7: Transmission

For example, if the third digit is “3,” the issue is related to the ignition system or a misfire.

3.4 Specific Code Details

The last two characters (digits) provide specific details about the fault. These digits help pinpoint the exact problem within the affected system.

For instance, in the code P0420, the “20” indicates a specific problem with the catalytic converter in the powertrain system.

Example: Decoding P0301

- P: Powertrain

- 0: Standardized Code

- 3: Ignition System or Misfire

- 01: Cylinder 1 Misfire

This code indicates a misfire in cylinder 1 of the engine.

Need Help Decoding Your Codes?

If you find yourself struggling to interpret an OBD-II code, don’t hesitate to reach out to CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880. Our experts are ready to assist you with accurate and reliable interpretations.

4. How to Effectively Clear OBD-II Codes?

Clearing OBD-II codes should be done with caution. It’s generally not advisable to clear codes without addressing the underlying issue, as the problem will likely return. However, there are situations where clearing a code is necessary, such as after completing a repair.

4.1 Using an OBD-II Scanner

An OBD-II scanner can both read and clear diagnostic trouble codes (DTCs). After addressing the issue causing the code, use the scanner to clear it.

Steps to Clear Codes with a Scanner:

- Connect the scanner to the OBD-II port (usually under the dashboard).

- Turn on the ignition (but don’t start the engine).

- Navigate to the “Clear Codes” or “Erase Codes” option in the scanner menu.

- Follow the prompts to clear the codes.

- Disconnect the scanner.

4.2 Performing a Drive Cycle

Some codes will clear automatically after a series of successful drive cycles. A drive cycle involves driving the vehicle under specific conditions to allow the system to retest and verify that the issue is resolved.

Typical Drive Cycle Conditions:

- Start the engine and allow it to reach operating temperature.

- Drive at a steady speed (e.g., 45-55 mph) for a set period (e.g., 5-10 minutes).

- Perform several accelerations and decelerations.

- Allow the vehicle to idle for a few minutes.

Refer to your vehicle’s service manual for the specific drive cycle recommended by the manufacturer.

4.3 Consulting a Professional Mechanic

If you are unsure about clearing codes or suspect a more significant issue, consult a professional mechanic. Mechanics have the expertise and tools to accurately diagnose and repair the problem, ensuring that the code doesn’t return.

Benefits of Professional Assistance:

- Accurate Diagnosis: Mechanics can pinpoint the root cause of the issue.

- Proper Repairs: Ensure the problem is fixed correctly, preventing further damage.

- Thorough Inspections: Mechanics can check related components and systems to ensure everything is in good working order.

Ready for Expert Advice?

Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880 for professional diagnostics and code clearing services.

5. How to Prevent OBD-II Codes from Appearing?

Preventing OBD-II codes is key to avoiding costly repairs and maintaining your vehicle’s optimal performance.

5.1 Regular Vehicle Maintenance

Regular maintenance is the most effective way to prevent OBD-II codes. Routine inspections, fluid changes, and timely repairs can address small issues before they escalate.

Essential Maintenance Tasks:

- Oil Changes: Regular oil changes keep the engine lubricated and prevent wear.

- Air Filter Replacements: Clean air filters ensure proper airflow to the engine.

- Spark Plug Inspections: Faulty spark plugs can cause misfires and trigger OBD-II codes.

- Brake System Checks: Regular brake inspections ensure safe and reliable braking.

- Tire Rotations: Rotating tires helps maintain even wear and prolong tire life.

Maintenance Schedule:

Adhere to the manufacturer’s recommended maintenance schedule, as outlined in your vehicle’s owner’s manual.

5.2 Using Quality Fuel and Fluids

Using high-quality fuel and fluids is crucial for preventing OBD-II codes. Low-quality fluids can lead to increased wear, while inferior fuel can cause incomplete combustion and emissions issues.

Fuel Recommendations:

- Choose reputable gas stations.

- Use high-quality fuel that meets or exceeds recommended octane ratings.

Fluid Recommendations:

- Use manufacturer-recommended fluids, such as engine oil, transmission fluid, coolant, and brake fluid.

- Regularly check and top up fluids to ensure they remain at the correct levels.

Partner with CARDIAGTECH.NET for Maintenance Tools

For all your maintenance needs, CARDIAGTECH.NET offers a wide range of diagnostic tools and equipment. Contact us at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880 to learn more.

6. Utilizing OBD-II Codes for Enhanced Fleet Management

For fleet managers, understanding and managing OBD-II codes efficiently can lead to significant cost savings and improved vehicle uptime.

6.1 Centralized Code Tracking

Centralizing code tracking involves gathering OBD-II code data from all fleet vehicles into one system. This simplifies data management and access, allowing fleet managers to quickly identify trends and potential issues.

Benefits of Centralized Tracking:

- Real-time insights into code occurrences.

- Analysis of historical code data to identify patterns.

- Improved maintenance planning and resource allocation.

6.2 Implementing Ongoing Fleet Monitoring

Ongoing monitoring uses telematics systems to collect real-time data from fleet vehicles, including vehicle location, performance metrics, and OBD-II code occurrences.

Advantages of Fleet Monitoring:

- Early detection of OBD-II codes and associated issues.

- Swift responses to minimize vehicle downtime.

- Proactive maintenance to prevent major breakdowns.

- Cost reduction through optimized vehicle performance and fuel efficiency.

6.3 Prioritizing Repairs Based on Severity

Prioritize repairs based on the severity and potential impact of OBD-II codes on vehicle operation. High-severity codes should be addressed promptly to minimize downtime and maintain uninterrupted operations.

Prioritization Guidelines:

- High Severity: Address immediately to prevent major breakdowns.

- Medium Severity: Schedule for repair within a week.

- Low Severity: Schedule for repair during planned maintenance intervals.

Maximize Your Fleet’s Efficiency with CARDIAGTECH.NET

Let CARDIAGTECH.NET help you optimize your fleet management with our advanced diagnostic tools. Reach out to us at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880 to discover how we can improve your fleet’s performance and reduce downtime.

7. How Do Oxygen Sensors Affect OBD-II Codes?

Oxygen sensors play a crucial role in your vehicle’s emission control system. They monitor the amount of oxygen in the exhaust gases to help the engine control module (ECM) adjust the air-fuel mixture for optimal combustion. Faulty oxygen sensors can trigger various OBD-II codes, affecting fuel efficiency and emissions.

7.1 Understanding Oxygen Sensor Function

Oxygen sensors are located in the exhaust system, typically before and after the catalytic converter. They send voltage signals to the ECM, indicating whether the air-fuel mixture is lean (too much oxygen) or rich (too little oxygen).

Key Functions of Oxygen Sensors:

- Monitoring Air-Fuel Mixture: Ensure the engine receives the correct ratio of air and fuel.

- Optimizing Combustion: Improve fuel efficiency and reduce emissions.

- Catalytic Converter Efficiency: Help the ECM monitor the performance of the catalytic converter.

7.2 Common OBD-II Codes Related to Oxygen Sensors

Faulty oxygen sensors can trigger a range of OBD-II codes. Here are some common examples:

| Code | Description | Possible Causes |

|---|---|---|

| P0130 | O2 Sensor Circuit Malfunction (Bank 1, Sensor 1) | Faulty sensor, wiring issues, exhaust leaks |

| P0131 | O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1) | Faulty sensor, wiring issues, lean air-fuel mixture |

| P0132 | O2 Sensor Circuit High Voltage (Bank 1, Sensor 1) | Faulty sensor, wiring issues, rich air-fuel mixture |

| P0133 | O2 Sensor Circuit Slow Response (Bank 1, Sensor 1) | Aged sensor, exhaust leaks, contamination |

| P0135 | O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1) | Faulty sensor, wiring issues, heater circuit failure |

| P0141 | O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 2) | Faulty sensor, wiring issues, heater circuit failure |

| P0171 | System Too Lean (Bank 1) | Vacuum leak, faulty oxygen sensor, low fuel pressure |

| P0174 | System Too Lean (Bank 2) | Vacuum leak, faulty oxygen sensor, low fuel pressure |

| P0420 | Catalyst System Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, oxygen sensor issues |

7.3 Diagnosing and Resolving Oxygen Sensor Issues

Diagnosing oxygen sensor issues typically involves using an OBD-II scanner to read the fault codes and inspecting the sensors and their wiring.

Steps for Diagnosing Oxygen Sensor Problems:

- Read OBD-II Codes: Use a scanner to identify any oxygen sensor-related codes.

- Inspect Sensors: Check the sensors for physical damage or contamination.

- Check Wiring: Inspect the wiring and connectors for damage or corrosion.

- Test Sensor Output: Use a multimeter to test the sensor’s voltage output.

If the sensor is faulty, it should be replaced. Ensure you use a high-quality replacement sensor that meets your vehicle’s specifications.

Ensure Accurate Readings with CARDIAGTECH.NET Tools

CARDIAGTECH.NET offers advanced diagnostic tools to accurately test and diagnose oxygen sensor issues. Contact us at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880 to learn more.

8. How Do Catalytic Converters Relate to OBD-II Codes?

Catalytic converters are essential components of your vehicle’s emission control system, responsible for reducing harmful pollutants in the exhaust gases. When a catalytic converter isn’t functioning correctly, it can trigger specific OBD-II codes, indicating potential environmental and performance issues.

8.1 Understanding Catalytic Converter Function

A catalytic converter uses chemical reactions to convert harmful gases like carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less harmful substances like carbon dioxide (CO2), water (H2O), and nitrogen (N2).

Key Functions of Catalytic Converters:

- Reducing Emissions: Convert harmful pollutants into less harmful gases.

- Environmental Protection: Help meet emission standards and protect the environment.

- Engine Performance: Ensure proper exhaust flow for optimal engine performance.

8.2 Common OBD-II Codes Related to Catalytic Converters

A failing catalytic converter can trigger several OBD-II codes. Here are some common examples:

| Code | Description | Possible Causes |

|---|---|---|

| P0420 | Catalyst System Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, oxygen sensor issues |

| P0421 | Warm Up Catalyst Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, oxygen sensor issues |

| P0422 | Main Catalyst Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, oxygen sensor issues |

| P0430 | Catalyst System Efficiency Below Threshold (Bank 2) | Faulty catalytic converter, exhaust leaks, oxygen sensor issues |

| P0431 | Warm Up Catalyst Efficiency Below Threshold (Bank 2) | Faulty catalytic converter, exhaust leaks, oxygen sensor issues |

| P0432 | Main Catalyst Efficiency Below Threshold (Bank 2) | Faulty catalytic converter, exhaust leaks, oxygen sensor issues |

| P0136 | O2 Sensor Circuit Malfunction (Bank 1, Sensor 2) | Faulty oxygen sensor, wiring issues, exhaust leaks, catalytic converter issues |

| P0137 | O2 Sensor Circuit Low Voltage (Bank 1, Sensor 2) | Faulty oxygen sensor, wiring issues, exhaust leaks, catalytic converter issues |

| P0138 | O2 Sensor Circuit High Voltage (Bank 1, Sensor 2) | Faulty oxygen sensor, wiring issues, exhaust leaks, catalytic converter issues |

8.3 Diagnosing and Resolving Catalytic Converter Issues

Diagnosing catalytic converter issues involves using an OBD-II scanner to read the fault codes and inspecting the converter and related components.

Steps for Diagnosing Catalytic Converter Problems:

- Read OBD-II Codes: Use a scanner to identify any catalytic converter-related codes.

- Inspect the Converter: Check the converter for physical damage or corrosion.

- Check for Exhaust Leaks: Inspect the exhaust system for leaks before and after the converter.

- Test Oxygen Sensors: Verify the proper functioning of the oxygen sensors.

- Perform a Backpressure Test: Measure the exhaust backpressure to check for blockage in the converter.

If the catalytic converter is faulty, it should be replaced. Ensure you use a high-quality replacement that meets your vehicle’s specifications.

Get the Right Tools for Emission Diagnostics with CARDIAGTECH.NET

CARDIAGTECH.NET offers advanced diagnostic tools to accurately test and diagnose catalytic converter issues. Contact us at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880 to learn more.

9. How Do Fuel System Issues Trigger OBD-II Codes?

The fuel system is critical for delivering the right amount of fuel to the engine for optimal combustion. Issues within the fuel system can trigger various OBD-II codes, affecting fuel efficiency, engine performance, and emissions.

9.1 Understanding Fuel System Function

The fuel system includes components such as the fuel pump, fuel injectors, fuel filter, and fuel pressure regulator. These components work together to deliver fuel from the fuel tank to the engine’s cylinders.

Key Functions of the Fuel System:

- Fuel Delivery: Supply fuel from the tank to the engine.

- Fuel Filtration: Remove contaminants from the fuel.

- Fuel Pressure Regulation: Maintain proper fuel pressure for optimal combustion.

- Fuel Injection: Precisely inject fuel into the cylinders.

9.2 Common OBD-II Codes Related to Fuel System Issues

Problems within the fuel system can trigger a range of OBD-II codes. Here are some common examples:

| Code | Description | Possible Causes |

|---|---|---|

| P0087 | Fuel Rail/System Pressure – Too Low | Faulty fuel pump, clogged fuel filter, fuel pressure regulator issues |

| P0088 | Fuel Rail/System Pressure – Too High | Faulty fuel pressure regulator, restricted fuel return line |

| P0171 | System Too Lean (Bank 1) | Vacuum leak, faulty oxygen sensor, low fuel pressure, faulty fuel injector |

| P0172 | System Too Rich (Bank 1) | High fuel pressure, faulty fuel injector, faulty oxygen sensor |

| P0201 | Injector Circuit Malfunction – Cylinder 1 | Faulty fuel injector, wiring issues, injector driver circuit problems |

| P0202 | Injector Circuit Malfunction – Cylinder 2 | Faulty fuel injector, wiring issues, injector driver circuit problems |

| P0230 | Fuel Pump Primary Circuit Malfunction | Faulty fuel pump relay, wiring issues, fuel pump problems |

| P0440 | Evaporative Emission Control System Malfunction | Leaks in the EVAP system, faulty gas cap, faulty purge valve |

| P0455 | Evaporative Emission Control System Leak Detected (Gross Leak) | Leaks in the EVAP system, faulty gas cap, faulty purge valve |

9.3 Diagnosing and Resolving Fuel System Issues

Diagnosing fuel system issues involves using an OBD-II scanner to read the fault codes and inspecting the fuel system components.

Steps for Diagnosing Fuel System Problems:

- Read OBD-II Codes: Use a scanner to identify any fuel system-related codes.

- Check Fuel Pressure: Use a fuel pressure gauge to measure the fuel pressure.

- Inspect Fuel Injectors: Check the fuel injectors for leaks or clogs.

- Check Fuel Filter: Inspect the fuel filter for clogs.

- Check Fuel Pump: Test the fuel pump’s performance.

- Inspect Fuel Lines: Inspect the fuel lines for leaks or damage.

If any fuel system component is faulty, it should be repaired or replaced.

Optimize Fuel Efficiency with CARDIAGTECH.NET Tools

CARDIAGTECH.NET provides the diagnostic tools you need to accurately diagnose and resolve fuel system issues, ensuring optimal engine performance and fuel efficiency. Contact us at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880 to learn more.

10. What Role Do Vacuum Leaks Play in Generating OBD-II Codes?

Vacuum leaks can significantly impact engine performance and emissions, often triggering various OBD-II codes. Understanding the role of vacuum leaks and how to diagnose them is essential for maintaining your vehicle’s health.

10.1 Understanding Vacuum System Function

The vacuum system in a vehicle uses engine vacuum to operate various components, such as power brakes, the evaporative emission control (EVAP) system, and the positive crankcase ventilation (PCV) system.

Key Functions of the Vacuum System:

- Power Brakes: Provide assistance for braking.

- EVAP System: Control fuel vapor emissions.

- PCV System: Remove crankcase gases and reduce emissions.

- Air Conditioning: Operate the air conditioning system.

10.2 Common OBD-II Codes Related to Vacuum Leaks

Vacuum leaks can cause a variety of OBD-II codes. Here are some common examples:

| Code | Description | Possible Causes |

|---|---|---|

| P0171 | System Too Lean (Bank 1) | Vacuum leak, faulty oxygen sensor, low fuel pressure, faulty fuel injector |

| P0174 | System Too Lean (Bank 2) | Vacuum leak, faulty oxygen sensor, low fuel pressure, faulty fuel injector |

| P0300 | Random/Multiple Cylinder Misfire Detected | Vacuum leak, faulty spark plugs, ignition coil issues, fuel injector problem |

| P0440 | Evaporative Emission Control System Malfunction | Leaks in the EVAP system, faulty gas cap, vacuum leaks |

| P0455 | Evaporative Emission Control System Leak Detected (Gross Leak) | Leaks in the EVAP system, faulty gas cap, vacuum leaks |

| P0505 | Idle Air Control System Malfunction | Vacuum leaks, faulty IAC valve, throttle body issues |

| P1128 | Closed Loop Fueling Not Achieved – Bank 1 | Vacuum leaks, faulty oxygen sensor, fuel delivery problems |

| P1129 | Closed Loop Fueling Not Achieved – Bank 2 | Vacuum leaks, faulty oxygen sensor, fuel delivery problems |

10.3 Diagnosing and Resolving Vacuum Leaks

Diagnosing vacuum leaks involves using visual inspections, smoke tests, and other diagnostic techniques.

Steps for Diagnosing Vacuum Leaks:

- Visual Inspection: Check vacuum hoses, connectors, and intake manifold gaskets for cracks or damage.

- Smoke Test: Introduce smoke into the intake system and look for smoke escaping from leak points.

- Listen for Hissing: Listen for hissing sounds near vacuum lines and connections.

- Use a Vacuum Gauge: Monitor vacuum levels to identify abnormalities.

If a vacuum leak is found, repair or replace the damaged components.

Detect and Seal Vacuum Leaks with CARDIAGTECH.NET Tools

CARDIAGTECH.NET offers the diagnostic tools you need to accurately detect and resolve vacuum leaks, ensuring optimal engine performance and emissions. Contact us at 276 Reock St, City of Orange, NJ 07050, United States, or via WhatsApp at +1 (641) 206-8880 to learn more.

FAQ: Interpreting OBD-II Fault Codes

1. What is an OBD-II scanner, and how does it help in interpreting fault codes?

An OBD-II scanner is a diagnostic tool that connects to your vehicle’s onboard computer, reading and clearing diagnostic trouble codes (DTCs). It helps interpret fault codes by providing a numerical representation of the problem, allowing users to identify issues without guesswork. These scanners are invaluable for both preliminary diagnostics and verifying repairs.

2. How do I know if an OBD-II code is critical and requires immediate attention?

Critical OBD-II codes often relate to safety or major mechanical issues. Codes associated with brakes (C-codes), airbags (B-codes), or severe engine problems (P-codes like misfires) should be addressed immediately. The severity can be gauged by the code’s description; any code indicating a safety risk warrants immediate attention.

3. Can I fix an OBD-II issue myself, or should I always consult a mechanic?

Whether you can fix an OBD-II issue yourself depends on your mechanical skills and the complexity of the problem. Simple issues like replacing a gas cap or tightening a loose connection can be DIY fixes. However, complex issues involving engine, transmission, or safety systems should be handled by a professional mechanic to avoid further damage or safety risks.

4. What does it mean if the “Check Engine” light is flashing?

A flashing “Check Engine” light typically indicates a severe issue, such as an engine misfire that could damage the catalytic converter. This requires immediate attention. It’s advisable to stop driving as soon as safely possible and have the vehicle inspected by a mechanic to prevent further damage.

5. How often should I scan my car for OBD-II fault codes?

You should scan your car for OBD-II fault codes whenever the “Check Engine” light comes on or if you notice any unusual symptoms like reduced performance, strange noises, or rough idling. Regular scanning can help catch minor issues before they escalate into major problems.

6. Are there any common misconceptions about OBD-II codes that I should be aware of?

Yes, one common misconception is that simply clearing the OBD-II code fixes the problem. Clearing the code only removes the symptom; the underlying issue remains and will likely trigger the code again. Another misconception is that all OBD-II codes require expensive repairs; some codes may be due to minor issues like a loose gas cap.

7. How do manufacturer-specific codes differ from generic OBD-II codes?

Manufacturer-specific codes (starting with “1”) provide more detailed information about issues unique to a particular car make or model, while generic OBD-II codes (starting with “0”) are standardized across all vehicles. Manufacturer-specific codes help mechanics pinpoint the exact problem, leading to more accurate and efficient repairs.

8. Can weather conditions affect OBD-II fault codes?

Yes, extreme weather conditions can sometimes affect OBD-II fault codes. For example, cold weather can cause issues with battery performance, triggering codes related to the charging system. Similarly, high humidity can affect electrical connections and sensors, leading to false or intermittent codes.

9. What is the role of the Engine Control Module (ECM) in generating OBD-II codes?

The Engine Control Module (ECM) is the central computer in your vehicle that monitors various sensors and systems. When a sensor detects a problem, it sends a signal to the ECM, which then registers a corresponding OBD-II code. The ECM plays a critical role in diagnosing issues and ensuring the vehicle operates within specified parameters.

10. How can CARDIAGTECH.NET help me better understand and manage OBD-II fault codes?

CARDIAGTECH.NET offers a range of diagnostic tools and equipment designed to help you understand and manage OBD-II fault codes effectively. Our advanced scanners provide accurate readings, and our expert team is available to assist with code interpretation and troubleshooting. Contact us at 276 Reock St, City of Orange,