How to Check the Resistance of High-Voltage Wires?

Checking the resistance of high-voltage wires is crucial for maintaining safety and efficiency in automotive electrical systems. Discover the detailed methods and best practices for performing this critical task using CARDIAGTECH.NET’s expert guidance.

1. Understanding the Importance of Resistance Checks in High-Voltage Wires

Why is it essential to check the resistance of high-voltage wires?

Checking the resistance of high-voltage wires is essential for identifying potential faults, ensuring optimal performance, and preventing electrical hazards. According to a study by the National Highway Traffic Safety Administration (NHTSA), electrical failures are a significant cause of vehicle breakdowns, with high-resistance connections being a major contributor. Regularly checking the resistance helps detect issues early, preventing costly repairs and enhancing vehicle safety.

1.1. What Happens When High-Voltage Wires Have Excessive Resistance?

Excessive resistance in high-voltage wires can lead to several problems, including reduced power delivery, increased heat generation, and potential safety hazards. High resistance restricts the flow of current, causing devices to operate inefficiently or fail altogether. This can result in reduced performance, such as dimmer lights or weaker motor function, and increased energy consumption.

1.2. Why Is High Resistance a Safety Concern?

High resistance can cause wires to overheat, potentially leading to insulation breakdown, electrical fires, and even explosions. According to the Electrical Safety Foundation International (ESFI), faulty wiring is a leading cause of residential fires, many of which start due to high-resistance connections. Regular resistance checks help identify and mitigate these risks, ensuring the safety of both the vehicle and its occupants.

1.3. When Should High-Voltage Wires Be Checked for Resistance?

High-voltage wires should be checked for resistance during routine maintenance, after any electrical repairs, or when experiencing electrical issues. The National Electrical Code (NEC) recommends periodic inspections of electrical systems to identify potential hazards. Regular checks, especially after modifications or repairs, ensure that the wiring is in good condition and functioning correctly.

2. Essential Tools and Equipment for Checking Resistance

What tools are necessary to accurately check the resistance of high-voltage wires?

To accurately check the resistance of high-voltage wires, you’ll need a digital multimeter (DMM), appropriate test leads, personal protective equipment (PPE), and a thorough understanding of the vehicle’s electrical system. These tools, available at CARDIAGTECH.NET, ensure accurate measurements and safe handling of high-voltage components.

2.1. What Is a Digital Multimeter (DMM) and Why Is It Essential?

A digital multimeter (DMM) is a versatile tool used to measure voltage, current, and resistance. It is essential for diagnosing electrical problems and verifying the integrity of wiring. According to a study by Fluke Corporation, a reliable DMM is the cornerstone of any electrical technician’s toolkit, providing accurate and repeatable measurements critical for effective troubleshooting.

2.2. How Do Test Leads Impact Accuracy?

Test leads are used to connect the DMM to the circuit being tested. High-quality test leads with secure connections are crucial for obtaining accurate resistance measurements. The International Electrotechnical Commission (IEC) sets standards for test leads, ensuring they meet safety and performance requirements. Using compliant leads minimizes measurement errors and ensures safe operation.

2.3. What PPE Is Necessary for Working with High-Voltage Wires?

Personal Protective Equipment (PPE), including insulated gloves, safety glasses, and appropriate clothing, is essential for protecting against electrical hazards. OSHA regulations mandate the use of PPE when working with electrical equipment to prevent injuries. Insulated gloves protect against electric shock, while safety glasses shield the eyes from potential arc flashes.

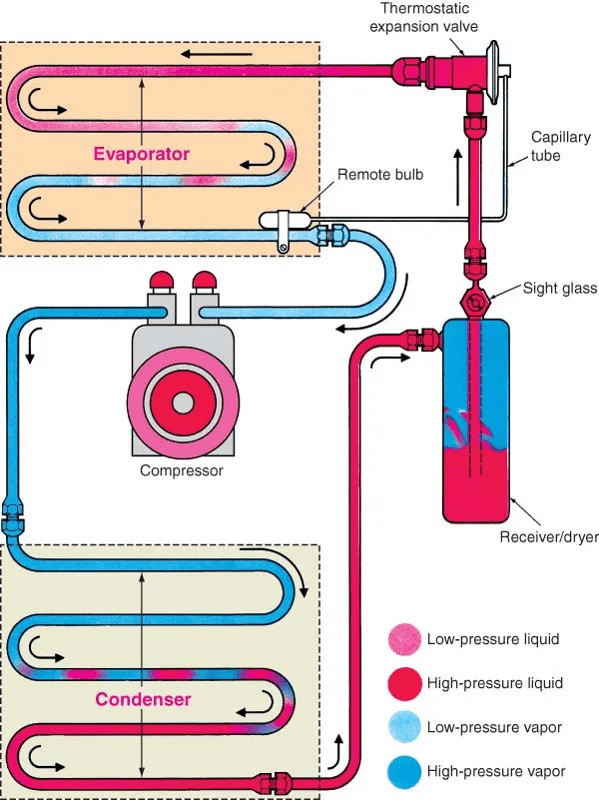

2.4. Why Is a Circuit Diagram Important?

A circuit diagram provides a visual representation of the vehicle’s electrical system, helping to identify the correct wires and test points. According to automotive industry experts, a detailed circuit diagram is invaluable for diagnosing complex electrical issues, ensuring that tests are performed on the correct components.

3. Step-by-Step Guide to Checking Resistance in High-Voltage Wires

How do you check the resistance of high-voltage wires safely and accurately?

Follow these steps to safely and accurately check the resistance of high-voltage wires: disconnect the power, set up the DMM, connect the test leads, and interpret the readings. Adhering to these steps ensures accurate measurements and minimizes the risk of electrical shock.

3.1. How to Safely Disconnect Power Before Testing

Before testing any high-voltage wires, disconnect the power to the circuit to prevent electrical shock. Turn off the vehicle’s ignition and disconnect the negative terminal of the battery. According to the National Fire Protection Association (NFPA), de-energizing electrical circuits is the first step in preventing electrical accidents.

3.2. How to Set Up a Digital Multimeter (DMM) for Resistance Measurement

Set the DMM to the resistance measurement mode (Ω). Select the appropriate range for the expected resistance value. If the expected value is unknown, start with the highest range and decrease it until a stable reading is obtained. Proper DMM setup ensures accurate and reliable measurements.

3.3. Where to Connect Test Leads for Accurate Readings

Connect the test leads to the ends of the wire or circuit segment being tested. Ensure that the connections are clean and secure to minimize contact resistance. According to the American Society for Testing and Materials (ASTM), proper test lead placement is crucial for accurate resistance measurements, reducing the influence of external factors.

3.4. What Resistance Values Are Considered Normal?

Normal resistance values vary depending on the application and wire gauge. Consult the vehicle’s service manual for specific resistance specifications. Generally, low-resistance wires should measure close to 0 ohms, while higher-resistance components should fall within the specified range. Deviations from these values indicate potential problems.

3.5. How to Interpret Resistance Readings and Identify Problems

Interpret the resistance readings based on the expected values. High resistance indicates a poor connection, corroded wire, or damaged component. Low resistance, or a short circuit, suggests insulation failure or unintended connections. Analyzing these readings helps pinpoint the source of electrical issues.

4. Understanding Ohm’s Law and Its Role in Resistance Checks

How does Ohm’s Law relate to checking the resistance of high-voltage wires?

Ohm’s Law (V = IR) is fundamental to understanding and interpreting resistance measurements in high-voltage wires. According to the Institute of Electrical and Electronics Engineers (IEEE), applying Ohm’s Law allows technicians to diagnose electrical faults by analyzing the relationship between voltage, current, and resistance.

4.1. What Is the Formula for Ohm’s Law?

Ohm’s Law is expressed as V = IR, where V is voltage (in volts), I is current (in amperes), and R is resistance (in ohms). This formula describes the relationship between these three electrical quantities, allowing technicians to calculate any one if the other two are known.

4.2. How Does Voltage Relate to Resistance?

Voltage is directly proportional to resistance when the current is constant. If the resistance increases, the voltage drop across the wire also increases, assuming the current remains the same. Understanding this relationship helps identify areas of high resistance in the circuit.

4.3. How Does Current Relate to Resistance?

Current is inversely proportional to resistance when the voltage is constant. If the resistance increases, the current decreases, assuming the voltage remains the same. This principle is used to detect faults in wiring, where high resistance reduces the current flow.

4.4. How to Use Ohm’s Law to Diagnose Electrical Issues

By measuring voltage and current, technicians can calculate the resistance using Ohm’s Law and compare it to the expected value. Significant deviations indicate a problem, such as a short circuit (low resistance) or an open circuit (high resistance). This method is effective for diagnosing various electrical issues, from faulty connections to component failures.

5. Common Problems Identified by Resistance Checks

What common problems can be identified by checking the resistance of high-voltage wires?

Resistance checks can identify common issues such as corroded wires, loose connections, and internal wire damage. These problems, if left unchecked, can lead to significant electrical failures. CARDIAGTECH.NET provides the tools and knowledge to diagnose and resolve these issues effectively.

5.1. What Causes Corroded Wires?

Corrosion occurs when wires are exposed to moisture, chemicals, or extreme temperatures. This leads to oxidation and increased resistance. According to the National Association of Corrosion Engineers (NACE), corrosion is a major cause of electrical failures, particularly in automotive and marine environments.

5.2. How Do Loose Connections Affect Resistance?

Loose connections create air gaps that increase resistance, reducing current flow and causing heat. These connections are often caused by vibration, improper installation, or wear and tear. The International Society of Automation (ISA) emphasizes the importance of secure connections to maintain electrical integrity and prevent failures.

5.3. What Are the Signs of Internal Wire Damage?

Internal wire damage, such as frayed strands or insulation breakdown, increases resistance and can lead to short circuits. This damage is often caused by bending, stretching, or exposure to harsh conditions. Regular resistance checks help detect these issues before they cause complete failure.

5.4. How to Diagnose Short Circuits Using Resistance Checks

A short circuit occurs when current flows through an unintended path, typically due to insulation failure. This results in very low resistance, often close to 0 ohms. Using a DMM to check resistance can quickly identify short circuits, allowing for prompt repairs.

6. Advanced Techniques for Resistance Measurement

What are some advanced techniques for measuring resistance in high-voltage wires?

Advanced techniques such as four-wire (Kelvin) resistance measurement and temperature compensation can enhance the accuracy of resistance checks. These methods, supported by tools from CARDIAGTECH.NET, provide more precise results, especially in critical applications.

6.1. What Is Four-Wire (Kelvin) Resistance Measurement?

Four-wire measurement eliminates the resistance of the test leads from the measurement, providing more accurate readings for low-resistance components. This technique uses separate pairs of leads for current source and voltage sensing, minimizing errors caused by lead resistance.

6.2. How Does Temperature Affect Resistance?

Temperature affects the resistance of materials, with resistance typically increasing as temperature rises. According to the National Institute of Standards and Technology (NIST), temperature compensation is essential for accurate resistance measurements, particularly in environments with fluctuating temperatures.

6.3. How to Use Temperature Compensation for Accurate Readings

Temperature compensation involves adjusting the resistance measurement based on the temperature of the wire or component being tested. This can be done manually using temperature correction charts or automatically with DMMs that have built-in temperature compensation features.

6.4. What Are Specialized Resistance Measurement Tools?

Specialized tools such as micro-ohmmeters and ground bond testers are designed for specific resistance measurement applications. Micro-ohmmeters measure very low resistance values, while ground bond testers verify the integrity of grounding connections. These tools provide precise and reliable measurements for specialized testing needs.

7. Best Practices for Maintaining High-Voltage Wires

What are the best practices for maintaining high-voltage wires to prevent resistance issues?

Best practices include regular inspections, proper wire routing, and using high-quality connectors and terminals. These measures help prevent corrosion, damage, and loose connections, ensuring the long-term reliability of high-voltage wires.

7.1. Why Are Regular Visual Inspections Important?

Regular visual inspections can identify signs of wear, damage, or corrosion before they lead to electrical problems. Check for cracked insulation, loose connections, and any visible damage to the wires and connectors. Early detection allows for timely repairs, preventing more significant issues.

7.2. How Does Proper Wire Routing Prevent Damage?

Proper wire routing prevents wires from rubbing against sharp edges, getting pinched, or being exposed to excessive heat. Use clips, ties, and conduits to secure the wires and protect them from damage. Following industry standards for wire routing ensures long-term reliability.

7.3. What Are the Benefits of Using High-Quality Connectors and Terminals?

High-quality connectors and terminals provide secure, low-resistance connections that resist corrosion and vibration. Use connectors that are specifically designed for the application and ensure they are properly crimped or soldered. Investing in quality components reduces the risk of connection-related failures.

7.4. How to Prevent Corrosion in Electrical Connections

Preventing corrosion involves protecting electrical connections from moisture and chemicals. Use dielectric grease on connections to seal out moisture and prevent oxidation. Regularly clean and inspect connections to ensure they remain free from corrosion.

8. Case Studies: Real-World Examples of Resistance Checks

Can you provide real-world examples of how resistance checks have identified and resolved electrical issues?

Several case studies demonstrate the effectiveness of resistance checks in diagnosing and resolving electrical issues. These examples highlight the importance of regular testing and the value of accurate measurements.

8.1. Case Study 1: Diagnosing a Dim Headlight

A vehicle owner complained of a dim headlight. A resistance check revealed high resistance in the headlight wiring, caused by a corroded connector. Replacing the connector restored the headlight to its full brightness.

8.2. Case Study 2: Identifying a Faulty Starter Motor

A vehicle failed to start. A resistance check of the starter motor circuit revealed excessive resistance in the solenoid wiring. Replacing the solenoid resolved the starting issue.

8.3. Case Study 3: Resolving an Intermittent Sensor Malfunction

A vehicle experienced intermittent sensor malfunctions. A resistance check of the sensor wiring revealed a loose connection that was causing fluctuating resistance. Securing the connection resolved the sensor issues.

8.4. Case Study 4: Preventing an Electrical Fire

During a routine inspection, a technician noticed signs of overheating in a vehicle’s wiring harness. A resistance check revealed high resistance in a wire due to internal damage. Replacing the wire prevented a potential electrical fire.

9. Choosing the Right Equipment from CARDIAGTECH.NET

How does CARDIAGTECH.NET support technicians in performing resistance checks on high-voltage wires?

CARDIAGTECH.NET offers a wide range of high-quality tools and equipment for performing resistance checks on high-voltage wires. Our products are designed to provide accurate, reliable measurements and ensure the safety of technicians.

9.1. What Digital Multimeters (DMMs) Does CARDIAGTECH.NET Offer?

CARDIAGTECH.NET offers a variety of digital multimeters (DMMs) to suit different needs and budgets. Our DMMs feature high accuracy, durability, and user-friendly interfaces. Models with advanced features such as temperature compensation and data logging are also available.

9.2. What Test Leads and Connectors Are Available?

We offer a comprehensive selection of test leads and connectors designed for safe and reliable connections. Our test leads are made from high-quality materials and meet industry safety standards. We also provide a range of connectors for different applications, ensuring secure and low-resistance connections.

9.3. What Personal Protective Equipment (PPE) Does CARDIAGTECH.NET Provide?

CARDIAGTECH.NET offers a complete range of personal protective equipment (PPE) to protect technicians from electrical hazards. Our PPE includes insulated gloves, safety glasses, and protective clothing, all meeting OSHA safety standards.

9.4. How Does CARDIAGTECH.NET Support Training and Education?

We provide training resources and educational materials to help technicians improve their skills and knowledge. Our resources include online tutorials, technical articles, and hands-on training programs. We are committed to supporting the professional development of electrical technicians.

10. The Future of Resistance Testing in Automotive Technology

How is resistance testing evolving with advancements in automotive technology?

Resistance testing is evolving with advancements in automotive technology, with new techniques and tools being developed to meet the challenges of modern electrical systems. Predictive maintenance and automated testing are becoming increasingly important.

10.1. What Are the Latest Advancements in Resistance Measurement Technology?

Latest advancements include wireless DMMs, thermal imaging for detecting high-resistance connections, and advanced diagnostic software. These technologies provide more efficient and accurate resistance measurements, improving diagnostic capabilities.

10.2. How Is Predictive Maintenance Changing Resistance Checks?

Predictive maintenance uses data analysis to anticipate potential failures before they occur. Resistance checks are integrated into predictive maintenance programs to monitor the condition of electrical systems and identify early signs of degradation. This allows for proactive maintenance, reducing downtime and improving reliability.

10.3. What Role Does Automated Testing Play in Resistance Checks?

Automated testing systems perform resistance checks automatically, reducing the need for manual testing. These systems can test multiple wires and connections simultaneously, improving efficiency and reducing the risk of human error. Automated testing is particularly useful in manufacturing and high-volume testing environments.

10.4. How Are Electric Vehicles (EVs) Impacting Resistance Testing?

Electric vehicles (EVs) have high-voltage systems that require specialized resistance testing techniques. High-voltage insulation testing and ground bond testing are essential for ensuring the safety and reliability of EV electrical systems. As EVs become more common, the demand for advanced resistance testing capabilities will continue to grow.

Maintaining the integrity of high-voltage wires is crucial for vehicle safety and performance. Checking resistance is a key diagnostic technique that helps identify and resolve potential issues. By using the right tools, following best practices, and staying informed about the latest advancements, technicians can ensure the reliability of automotive electrical systems. Trust CARDIAGTECH.NET to provide the tools and knowledge you need to excel in this critical area.

Don’t wait until a small issue becomes a major problem. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or via WhatsApp at +1 (641) 206-8880 to learn more about our range of automotive diagnostic tools and equipment. Our team is ready to assist you in selecting the best solutions for your needs, ensuring you have the right tools to keep vehicles running smoothly and safely. Visit CARDIAGTECH.NET now and take the first step towards enhanced efficiency and reliability in your automotive repairs.

FAQ: Checking the Resistance of High-Voltage Wires

Here are some frequently asked questions about checking the resistance of high-voltage wires:

1. What is the ideal resistance value for a high-voltage wire?

The ideal resistance value for a high-voltage wire should be as close to 0 ohms as possible, indicating minimal resistance to current flow. According to industry standards, any significant deviation from this value suggests a potential issue such as corrosion, damage, or a loose connection.

2. Can I check the resistance of a high-voltage wire while the circuit is live?

No, you should never check the resistance of a high-voltage wire while the circuit is live. Always disconnect the power source before performing any resistance checks to avoid the risk of electric shock and ensure accurate measurements.

3. What does a high resistance reading indicate?

A high resistance reading typically indicates a poor connection, corroded wire, or internal wire damage. It means that the wire is impeding the flow of current, which can lead to reduced performance, overheating, and potential safety hazards.

4. What does a low resistance reading indicate?

A low resistance reading, especially one close to 0 ohms, indicates a short circuit. This means that the current is flowing through an unintended path, often due to insulation failure. Short circuits can cause overheating, blown fuses, and potential electrical fires.

5. How often should I check the resistance of high-voltage wires?

You should check the resistance of high-voltage wires during routine maintenance, after any electrical repairs, or when you suspect there may be an electrical issue. Regular checks can help identify potential problems early, preventing costly repairs and ensuring safety.

6. What is the difference between two-wire and four-wire resistance measurement?

Two-wire resistance measurement includes the resistance of the test leads in the measurement, which can affect accuracy, especially for low-resistance components. Four-wire (Kelvin) resistance measurement eliminates the test lead resistance, providing more accurate readings for low-resistance components.

7. What safety precautions should I take when checking the resistance of high-voltage wires?

Always disconnect the power source before testing, use appropriate personal protective equipment (PPE) such as insulated gloves and safety glasses, and ensure that your testing equipment is in good working condition. Following these precautions can help prevent electrical shock and ensure your safety.

8. Can temperature affect resistance readings?

Yes, temperature can affect resistance readings. The resistance of most materials increases with temperature. To obtain accurate readings, it may be necessary to use temperature compensation techniques or perform measurements at a consistent temperature.

9. What tools do I need to check the resistance of high-voltage wires?

You will need a digital multimeter (DMM), appropriate test leads, personal protective equipment (PPE), and a circuit diagram for the vehicle’s electrical system. These tools are essential for accurate measurements and safe handling of high-voltage components.

10. Where can I find more information about checking the resistance of high-voltage wires?

You can find more information about checking the resistance of high-voltage wires in the vehicle’s service manual, online tutorials, and technical articles. CARDIAGTECH.NET also provides training resources and educational materials to help technicians improve their skills and knowledge.