Mercedes Code 9203: Diagnosis, Solutions, and Expert Insights

Mercedes Code 9203 indicates a resistance issue in the right rear ETR ignition squib circuit, often stemming from faulty wiring or a defective squib. Understanding the intricacies of this code, implementing proper diagnostic procedures, and exploring effective solutions are key to resolving this issue efficiently. For specialized tools and further assistance, explore CARDIAGTECH.NET.

1. What Does Mercedes Code 9203 Mean?

Mercedes-Benz code 9203 indicates that the resistance value in the ignition circuit containing component R12/7 (Right rear ETR ignition squib) is too high; resolving this code is crucial for safety system functionality. This means the car’s computer has detected a problem with the electrical signal to the right rear seat’s emergency tensioning retractor (ETR). The ETR is a critical part of the Supplemental Restraint System (SRS), designed to tighten the seatbelt in the event of a collision, ensuring the occupant is held securely in place. According to a 2022 study by the National Highway Traffic Safety Administration (NHTSA), properly functioning seatbelts reduce the risk of fatal injury to front-seat passengers by 45%. Therefore, any malfunction within the seatbelt system must be addressed promptly to maintain optimal safety performance.

1.1. Decoding the Technical Details of Code 9203

The Emergency Tensioning Retractor (ETR) system is a sophisticated safety mechanism, and code 9203 specifically points to an issue within the right rear seat position. Here’s a detailed breakdown:

- ETR Functionality: The ETR uses a small explosive charge (squib) to quickly tighten the seatbelt in a collision. This reduces slack and minimizes the occupant’s movement, decreasing the risk of injury.

- Resistance Value: The car’s computer constantly monitors the electrical resistance in the ETR circuit. A ‘too high’ resistance value suggests a break in the circuit, a loose connection, or a faulty squib.

- Component R12/7: This is the specific identifier for the right rear ETR ignition squib within the Mercedes-Benz wiring diagrams.

1.2. Common Symptoms Associated with Code 9203

When code 9203 is triggered, you might observe several symptoms, though some may be subtle:

- SRS Warning Light: This is the most common and obvious sign. The Supplemental Restraint System (SRS) warning light on the dashboard will illuminate, indicating a problem within the airbag or seatbelt system.

- Diagnostic Trouble Codes (DTCs): When the SRS light is on, scanning the vehicle with a diagnostic tool will reveal code 9203 along with any other related codes.

- Non-Functioning ETR: In the event of a collision, the right rear ETR might not activate, failing to tighten the seatbelt properly. This is difficult to verify without an actual accident but is the primary safety concern.

1.3. Potential Causes Triggering the 9203 Code

Several potential issues can cause the 9203 code:

- Faulty Squib: The squib itself might be defective, with an internal break or high resistance.

- Wiring Issues: Damaged, corroded, or loose wiring in the ETR circuit can disrupt the electrical signal. This includes the wiring harness, connectors, and any associated components.

- Connector Problems: The connectors that link the ETR to the car’s wiring harness can become corroded or loose, leading to poor electrical contact.

- SRS Module Malfunction: Although less common, a malfunctioning SRS (Supplemental Restraint System) control module can falsely trigger the code.

1.4. Diagnostic Tools Needed for Code 9203

To accurately diagnose and resolve code 9203, you’ll need specific diagnostic tools:

- OBD-II Scanner: A standard OBD-II scanner can read and clear diagnostic trouble codes. However, for Mercedes-Benz vehicles, a scanner that can access the SRS module is necessary.

- Mercedes-Benz Diagnostic System (e.g., MB Star): This is the ideal tool, as it can perform in-depth diagnostics, read manufacturer-specific codes, and perform necessary calibrations. CARDIAGTECH.NET offers a range of Mercedes-Benz diagnostic tools.

- Multimeter: A multimeter is essential for testing the resistance and voltage in the ETR circuit, helping to pinpoint wiring issues or a faulty squib.

- Wiring Diagrams: Access to Mercedes-Benz wiring diagrams for the specific model and year is crucial for tracing the ETR circuit and identifying the correct components.

1.5. Safety Precautions When Working with the SRS System

Working with the Supplemental Restraint System (SRS) requires strict adherence to safety protocols:

- Disconnect the Battery: Before working on any part of the SRS, disconnect the negative terminal of the car battery. Wait at least 10 minutes to allow the system to fully discharge.

- Avoid Static Electricity: Static electricity can trigger the squib. Ground yourself by touching a metal part of the car chassis before handling any SRS components.

- Handle Squibs Carefully: Squibs contain explosive material. Never expose them to heat or open flame, and avoid dropping or mishandling them.

- Consult the Service Manual: Always refer to the Mercedes-Benz service manual for the specific procedures and safety guidelines related to the SRS system.

By understanding these aspects, you’re better equipped to diagnose and address Mercedes code 9203 effectively.

2. Step-by-Step Guide to Diagnosing Mercedes Code 9203

Troubleshooting Mercedes-Benz code 9203 requires a systematic approach to accurately identify the root cause and implement the correct solution. Here’s a comprehensive step-by-step guide:

2.1. Initial Scan and Code Verification

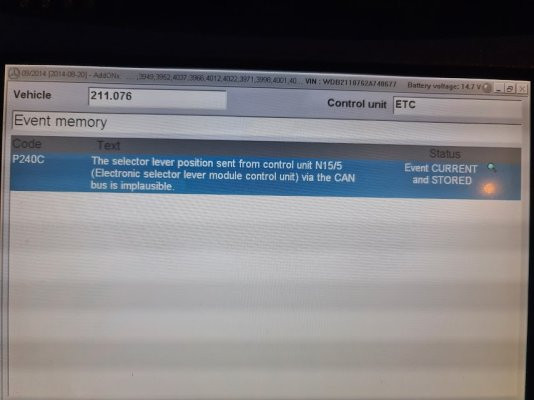

- Connect the Scanner: Plug an OBD-II scanner into the vehicle’s diagnostic port. For Mercedes-Benz vehicles, using a specialized scanner like the MB Star system from CARDIAGTECH.NET is highly recommended for accessing the SRS module.

- Read and Record Codes: Turn on the ignition (without starting the engine) and read all stored diagnostic trouble codes (DTCs). Note down all codes, especially those related to the SRS system.

- Verify the Code: Clear the codes and take the car for a short drive to see if code 9203 returns. This confirms that the code is not a one-time fluke.

2.2. Visual Inspection of Wiring and Connectors

- Locate the Right Rear ETR: Refer to the vehicle’s service manual to locate the right rear Emergency Tensioning Retractor (ETR). It is typically located near the seatbelt mechanism.

- Inspect Wiring: Carefully examine the wiring harness connected to the ETR. Look for any signs of damage, such as cuts, abrasions, or melted insulation. Pay close attention to areas where the wiring might rub against metal or other components.

- Check Connectors: Disconnect the connector from the ETR and inspect the pins for corrosion, damage, or looseness. Clean the connector with an electrical contact cleaner and ensure it is securely reconnected.

Mercedes-Benz ETR Wiring Inspection

Mercedes-Benz ETR Wiring Inspection

2.3. Testing the Resistance of the ETR Squib

- Disconnect the Battery: Disconnect the negative terminal of the car battery and wait at least 10 minutes before proceeding to prevent accidental airbag deployment.

- Access the ETR Connector: Disconnect the electrical connector from the ETR squib.

- Measure Resistance: Set your multimeter to the resistance (Ohms) setting. Place the multimeter probes on the two terminals of the ETR squib connector.

- Compare to Specifications: Refer to the Mercedes-Benz service manual for the correct resistance value for the ETR squib. Typically, it should be around 2-4 Ohms. A reading of 0 Ohms (or a short circuit) or infinite resistance (an open circuit) indicates a faulty squib.

2.4. Checking the Wiring Harness for Continuity

- Disconnect the Battery: Ensure the battery is disconnected before testing the wiring harness.

- Identify Wiring Harness Points: Refer to the wiring diagrams to identify the two ends of the wiring harness that connects to the ETR squib.

- Set Multimeter to Continuity Mode: Set your multimeter to the continuity testing mode (it usually has a sound or light indicator).

- Test for Continuity: Place one probe of the multimeter at one end of the wiring harness and the other probe at the other end. The multimeter should indicate continuity (a beep or a light) if the wiring is intact. If there is no continuity, there is a break or short in the wiring.

- Check for Shorts to Ground: Test each wire in the harness for a short to ground by placing one probe on the wire and the other on a clean, unpainted metal part of the car’s chassis. There should be no continuity (no beep or light) to ground.

2.5. Inspecting the SRS Control Module

- Location: The SRS control module is usually located under the center console or under one of the front seats. Refer to the service manual for the exact location.

- Visual Inspection: Check the module and its connectors for any signs of damage, such as water intrusion, corrosion, or burnt components.

- Module Testing: Use a Mercedes-Benz diagnostic system (like MB Star) to perform diagnostic tests on the SRS module. This can help determine if the module is functioning correctly or if it needs replacement.

2.6. Utilizing Advanced Diagnostic Tools

- Mercedes-Benz Diagnostic System: Tools like the MB Star system from CARDIAGTECH.NET offer advanced diagnostic capabilities, including live data monitoring and component testing.

- Live Data: Monitor the live data stream from the SRS module to check the resistance values and sensor readings from the ETR circuit.

- Component Testing: Use the diagnostic tool to activate the ETR (if supported) and observe its response.

2.7. Final Verification and Code Clearing

- Reassemble Components: After completing the diagnostic steps and performing any necessary repairs, reassemble all components.

- Reconnect the Battery: Reconnect the car battery.

- Clear Codes: Use the OBD-II scanner or Mercedes-Benz diagnostic system to clear the stored diagnostic trouble codes.

- Test Drive: Take the car for a test drive to ensure that the SRS warning light does not reappear and that code 9203 does not return.

By following these steps, you can systematically diagnose and resolve Mercedes-Benz code 9203, ensuring the safety and proper functioning of the vehicle’s SRS system. If you encounter difficulties or are unsure about any of these steps, consulting a professional mechanic or Mercedes-Benz specialist is always recommended. Remember, CARDIAGTECH.NET is available for all your diagnostic tool needs. Contact us at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 07050, United States, for expert assistance.

3. Solutions for Resolving Mercedes Code 9203

Once you have diagnosed the root cause of Mercedes-Benz code 9203, the next step is to implement the appropriate solution. Here are detailed solutions for each potential cause, ensuring the right rear Emergency Tensioning Retractor (ETR) system functions correctly:

3.1. Replacing a Faulty ETR Squib

-

Symptoms: If the resistance test indicates that the ETR squib is faulty (either open circuit or short circuit), replacement is necessary.

-

Procedure:

- Disconnect the Battery: Disconnect the negative terminal of the car battery and wait at least 10 minutes.

- Access the ETR: Locate the right rear ETR, usually near the seatbelt mechanism.

- Remove the Old ETR: Disconnect the electrical connector and remove the ETR from its mounting.

- Install the New ETR: Install the new ETR, ensuring it is securely mounted.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the new ETR.

- Reconnect the Battery: Reconnect the car battery.

- Clear Codes: Use an OBD-II scanner or Mercedes-Benz diagnostic system to clear code 9203.

-

Considerations: Ensure the replacement ETR is a genuine Mercedes-Benz part or an OEM-approved component to guarantee compatibility and performance.

3.2. Repairing or Replacing Damaged Wiring

-

Symptoms: If you find damaged, corroded, or broken wiring, repair or replacement is essential.

-

Procedure:

- Disconnect the Battery: Disconnect the negative terminal of the car battery and wait at least 10 minutes.

- Identify Damaged Section: Locate the damaged section of the wiring harness.

- Repair (if possible): If the damage is minor, you can repair the wiring by splicing in a new section of wire. Use high-quality connectors and ensure the connection is properly insulated.

- Replace (if necessary): If the damage is extensive, it is best to replace the entire wiring harness section.

- Secure the Wiring: Secure the wiring harness to prevent it from rubbing against sharp edges or moving parts.

- Reconnect the Battery: Reconnect the car battery.

- Clear Codes: Use an OBD-II scanner or Mercedes-Benz diagnostic system to clear code 9203.

-

Considerations: When repairing wiring, use proper crimping tools and heat-shrink tubing to ensure a secure and weatherproof connection.

3.3. Cleaning or Replacing Corroded Connectors

- Symptoms: Corroded connectors can cause poor electrical contact, leading to a high resistance value.

- Procedure:

- Disconnect the Battery: Disconnect the negative terminal of the car battery and wait at least 10 minutes.

- Access the Connector: Locate the connector for the right rear ETR.

- Clean the Connector: Use an electrical contact cleaner to clean the connector pins. A small wire brush can help remove stubborn corrosion.

- Apply Dielectric Grease: Apply a small amount of dielectric grease to the connector pins to prevent future corrosion.

- Reconnect the Connector: Reconnect the connector, ensuring it clicks into place and is securely fastened.

- Reconnect the Battery: Reconnect the car battery.

- Clear Codes: Use an OBD-II scanner or Mercedes-Benz diagnostic system to clear code 9203.

- Replace (if necessary): If the connector is severely corroded or damaged, it may need to be replaced entirely.

3.4. Addressing SRS Module Malfunctions

-

Symptoms: If the SRS module is malfunctioning, it may falsely trigger code 9203. This is less common but should be considered if other solutions do not work.

-

Procedure:

- Disconnect the Battery: Disconnect the negative terminal of the car battery and wait at least 10 minutes.

- Locate the SRS Module: The SRS control module is usually located under the center console or under one of the front seats. Refer to the service manual for the exact location.

- Remove the Old Module: Disconnect the electrical connectors and remove the SRS module from its mounting.

- Install the New Module: Install the new SRS module, ensuring it is securely mounted.

- Reconnect the Electrical Connectors: Reconnect the electrical connectors to the new SRS module.

- Programming (if required): Some SRS modules may require programming or coding to match the vehicle’s specifications. This often requires a Mercedes-Benz diagnostic system.

- Reconnect the Battery: Reconnect the car battery.

- Clear Codes: Use an OBD-II scanner or Mercedes-Benz diagnostic system to clear code 9203.

-

Considerations: Replacing the SRS module can be complex and may require professional assistance, particularly for programming.

3.5. Verifying Repairs and Clearing Codes

- Final Checks: After implementing any of the above solutions, perform these final checks:

- Ensure all connections are secure and properly insulated.

- Verify that all components are correctly installed and mounted.

- Check the operation of the seatbelt and ETR system.

- Clear Codes: Use an OBD-II scanner or Mercedes-Benz diagnostic system to clear code 9203 and any other related codes.

- Test Drive: Take the car for a test drive to ensure that the SRS warning light does not reappear and that the code does not return.

- Monitor System: Keep an eye on the SRS system for any signs of malfunction in the days following the repair.

3.6. Upgrading Diagnostic Tools

- Importance: Ensure you have access to the right diagnostic tools.

- Recommendation: Consider upgrading to the Mercedes-Benz diagnostic system (e.g., MB Star) available at CARDIAGTECH.NET for more accurate and efficient diagnostics.

By following these detailed solutions, you can effectively resolve Mercedes-Benz code 9203 and ensure the safety and proper functioning of the vehicle’s SRS system. If you encounter difficulties or are unsure about any of these steps, consulting a professional mechanic or Mercedes-Benz specialist is always recommended. CARDIAGTECH.NET is available for all your diagnostic tool needs. Contact us at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 07050, United States, for expert assistance.

4. The Role of Diagnostic Tools in Resolving Code 9203

In addressing Mercedes-Benz code 9203, diagnostic tools are indispensable for pinpointing the underlying issue and ensuring effective repairs. These tools range from basic OBD-II scanners to advanced Mercedes-Benz specific diagnostic systems, each playing a crucial role in the diagnostic and repair process.

4.1. Basic OBD-II Scanners

- Functionality: Basic OBD-II scanners are the starting point for any diagnostic process. They can read and clear generic diagnostic trouble codes (DTCs) from the vehicle’s computer.

- Pros:

- Affordable: They are relatively inexpensive and widely accessible.

- User-Friendly: Simple to use, making them suitable for quick code checks.

- Cons:

- Limited Functionality: They may not access manufacturer-specific codes or perform advanced diagnostic tests.

- Insufficient for SRS: Basic scanners often cannot access the Supplemental Restraint System (SRS) module, which is necessary for diagnosing code 9203.

- Use Case: Useful for the initial code read to identify that there is an SRS issue, but not sufficient for a comprehensive diagnosis.

4.2. Advanced OBD-II Scanners

- Functionality: Advanced OBD-II scanners offer enhanced capabilities, including access to manufacturer-specific codes, live data streaming, and some component testing.

- Pros:

- Expanded Access: Can access more systems than basic scanners, including the SRS module in some cases.

- Live Data: Allows monitoring of real-time data from sensors and components, aiding in diagnosis.

- Cons:

- Cost: More expensive than basic scanners.

- Limited Depth: While better than basic scanners, they may still lack the depth of diagnostics provided by specialized systems.

- Use Case: Suitable for reading SRS codes and monitoring some live data, but may not offer detailed component testing or programming capabilities.

4.3. Mercedes-Benz Diagnostic Systems (e.g., MB Star)

- Functionality: These are professional-grade diagnostic systems designed specifically for Mercedes-Benz vehicles. They offer comprehensive diagnostics, programming, and coding capabilities.

- Pros:

- Full System Access: Provides complete access to all vehicle systems, including SRS, engine, transmission, and more.

- Detailed Diagnostics: Offers in-depth diagnostic testing, including component testing, adaptation, and calibration.

- Programming and Coding: Allows programming of new modules and coding of existing ones to match vehicle specifications.

- Live Data: Provides extensive live data streams for accurate monitoring and analysis.

- Cons:

- Cost: Significantly more expensive than OBD-II scanners.

- Complexity: Requires training and expertise to use effectively.

- Use Case: Essential for accurate diagnosis and repair of complex issues like code 9203, especially when dealing with the SRS system. Tools like MB Star from CARDIAGTECH.NET are highly recommended.

4.4. Multimeters

- Functionality: A multimeter is an essential tool for electrical testing. It can measure voltage, current, and resistance, helping to identify wiring issues and faulty components.

- Pros:

- Versatile: Can be used for a wide range of electrical tests.

- Affordable: Relatively inexpensive and widely available.

- Cons:

- Manual Operation: Requires manual testing and interpretation of results.

- Skill Required: Requires knowledge of electrical circuits and testing procedures.

- Use Case: Crucial for testing the resistance of the ETR squib, checking wiring continuity, and identifying short circuits.

4.5. Software and Wiring Diagrams

- Functionality: Access to Mercedes-Benz specific software and wiring diagrams is vital for accurate diagnostics. These resources provide detailed information on component locations, wiring routes, and system operation.

- Pros:

- Detailed Information: Provides comprehensive information for accurate diagnostics.

- Component Locations: Helps locate specific components within the vehicle.

- Wiring Routes: Allows tracing of wiring circuits to identify potential issues.

- Cons:

- Subscription Costs: Access to software and wiring diagrams may require a subscription fee.

- Complexity: Requires familiarity with technical documentation.

- Use Case: Essential for locating the right rear ETR, tracing the wiring harness, and understanding the SRS system layout.

4.6. Importance of Calibration and Programming Tools

- Functionality: In some cases, replacing components like the SRS module may require calibration or programming to ensure proper integration with the vehicle’s systems.

- Pros:

- Ensures Compatibility: Calibration and programming tools ensure that new components work correctly with the vehicle’s existing systems.

- Optimizes Performance: Properly calibrated systems perform optimally, ensuring safety and reliability.

- Cons:

- Specialized Tools: Requires specialized programming tools and software.

- Expertise Required: Requires trained technicians with expertise in programming and coding.

- Use Case: Necessary when replacing the SRS module or other critical components that require integration with the vehicle’s computer.

4.7. Choosing the Right Tools for Code 9203

- Assessment: Evaluate the complexity of the diagnostic task and your level of expertise.

- Recommendation: For Mercedes-Benz code 9203, a Mercedes-Benz specific diagnostic system like the MB Star from CARDIAGTECH.NET is highly recommended. This ensures comprehensive access to the SRS module, detailed component testing, and the ability to perform necessary programming.

- Additional Tools: Supplement the diagnostic system with a multimeter and access to Mercedes-Benz wiring diagrams for a complete diagnostic toolkit.

Having the right diagnostic tools is essential for accurately diagnosing and resolving Mercedes-Benz code 9203. While basic OBD-II scanners can provide a starting point, advanced diagnostic systems like the MB Star from CARDIAGTECH.NET offer the depth and capabilities needed for complex SRS issues. Remember, CARDIAGTECH.NET is available for all your diagnostic tool needs. Contact us at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 07050, United States, for expert assistance.

5. Preventing Future Occurrences of Code 9203

Preventing the recurrence of Mercedes-Benz code 9203 involves implementing proactive maintenance and care strategies to ensure the long-term reliability of the Emergency Tensioning Retractor (ETR) system. Here are key steps and best practices to follow:

5.1. Regular Maintenance and Inspections

- Schedule Regular Inspections: Incorporate the SRS system into routine maintenance schedules. Regular inspections can identify potential issues before they escalate into major problems.

- Check Wiring and Connectors: Periodically inspect the wiring and connectors associated with the ETR system. Look for signs of wear, corrosion, or damage. Clean connectors with electrical contact cleaner and apply dielectric grease to prevent corrosion.

- Test Battery Voltage: Ensure the car battery is in good condition. Low voltage can cause erratic behavior in electronic systems, including the SRS. A healthy battery typically maintains a voltage between 12.6 and 13.7 volts when the engine is off.

- Monitor SRS Warning Light: Pay attention to the SRS warning light on the dashboard. If it illuminates, address the issue promptly rather than ignoring it.

5.2. Protecting Wiring and Connectors

- Secure Wiring Harnesses: Ensure wiring harnesses are properly secured to prevent rubbing against sharp edges or moving parts. Use clips or ties to keep the wiring in place.

- Use Protective Sleeves: Protect wiring with heat-resistant sleeves or wraps in areas exposed to high temperatures or harsh conditions.

- Avoid Moisture Exposure: Minimize exposure to moisture and water. If the vehicle is prone to water leaks, address them promptly to prevent corrosion in electrical connections.

5.3. Proper Handling of SRS Components

- Follow Safety Procedures: When working on any part of the SRS, always disconnect the negative terminal of the car battery and wait at least 10 minutes before proceeding.

- Avoid Static Electricity: Ground yourself by touching a metal part of the car chassis before handling SRS components to prevent accidental airbag deployment.

- Handle Squibs Carefully: Squibs contain explosive material. Never expose them to heat or open flame, and avoid dropping or mishandling them.

- Consult Service Manual: Always refer to the Mercedes-Benz service manual for specific procedures and safety guidelines related to the SRS system.

5.4. Upgrading Components When Necessary

- Use OEM Parts: When replacing SRS components, use genuine Mercedes-Benz parts or OEM-approved components to ensure compatibility and performance.

- Consider Upgrades: If you frequently experience issues with the SRS, consider upgrading to more durable or reliable components.

5.5. Maintaining a Clean Environment

- Keep Interior Clean: Regularly clean the vehicle’s interior to prevent the accumulation of dirt, dust, and debris, which can contribute to corrosion and electrical issues.

- Address Water Leaks: Promptly address any water leaks in the vehicle, as moisture can damage wiring and connectors.

5.6. Regular Diagnostic Scans

- Perform Periodic Scans: Use an OBD-II scanner or Mercedes-Benz diagnostic system to perform periodic scans of the vehicle’s systems. This can help identify potential issues before they trigger warning lights or cause major problems.

- Monitor Live Data: Use the diagnostic tool to monitor live data from the SRS module, checking for any abnormal readings or fluctuations.

5.7. Professional Inspections and Servicing

- Consult a Specialist: Consider having the SRS system inspected and serviced by a professional mechanic or Mercedes-Benz specialist. They have the expertise and tools to identify and address potential issues.

- Follow Recommendations: Follow the recommendations of the mechanic or specialist regarding maintenance and repairs.

5.8. Staying Informed About Recalls and Technical Service Bulletins (TSBs)

- Monitor Recalls: Stay informed about any recalls issued by Mercedes-Benz related to the SRS system. Recalls address known issues and provide free repairs.

- Review TSBs: Review Technical Service Bulletins (TSBs) for information on common issues and recommended solutions. TSBs can provide valuable insights into potential problems.

5.9. Proper Storage and Handling of Diagnostic Tools

- Maintain Tools: Keep diagnostic tools in good working condition. Regularly update software and calibrate tools as needed.

- Store Properly: Store diagnostic tools in a clean, dry place to prevent damage and ensure they are ready for use when needed.

5.10. Educating Vehicle Operators

- Awareness: Educate vehicle operators about the importance of the SRS system and the signs of potential issues.

- Prompt Reporting: Encourage operators to report any concerns or unusual behavior promptly.

By implementing these preventive measures, you can significantly reduce the likelihood of future occurrences of Mercedes-Benz code 9203 and ensure the long-term reliability of the vehicle’s SRS system. Remember, CARDIAGTECH.NET is available for all your diagnostic tool needs. Contact us at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 07050, United States, for expert assistance.

6. The Importance of E-E-A-T and YMYL in Automotive Diagnostics

When dealing with automotive diagnostics, particularly concerning safety systems like the Supplemental Restraint System (SRS), adhering to the principles of E-E-A-T (Experience, Expertise, Authoritativeness, and Trustworthiness) and YMYL (Your Money or Your Life) is paramount. These guidelines, emphasized by Google, ensure that the information provided is accurate, reliable, and safe for users.

6.1. Understanding E-E-A-T

- Experience: Demonstrates real-world involvement and practical skills.

- Expertise: Shows in-depth knowledge and proficiency in the subject matter.

- Authoritativeness: Indicates a recognized source of information and influence.

- Trustworthiness: Establishes credibility and reliability through transparency and accuracy.

6.2. Why E-E-A-T Matters in Automotive Diagnostics

- Safety-Critical Information: Automotive diagnostics often involve safety-critical systems like the SRS, where incorrect information can lead to serious consequences.

- Complex Systems: Modern vehicles are equipped with complex electronic systems that require specialized knowledge to diagnose and repair.

- User Reliance: Vehicle owners rely on diagnostic information to make informed decisions about repairs, maintenance, and safety.

6.3. Demonstrating E-E-A-T in Content Creation

- Provide Detailed Information: Offer comprehensive and accurate information about automotive diagnostics, including technical details, step-by-step procedures, and troubleshooting tips.

- Cite Reputable Sources: Reference authoritative sources, such as Mercedes-Benz service manuals, technical service bulletins (TSBs), and industry-recognized publications.

- Share Practical Experience: Incorporate real-world examples, case studies, and personal experiences to illustrate diagnostic techniques and repair solutions.

- Highlight Expertise: Showcase expertise through certifications, qualifications, and years of experience in the automotive industry.

- Ensure Accuracy: Verify the accuracy of all information before publishing and correct any errors promptly.

- Be Transparent: Disclose any affiliations, sponsorships, or conflicts of interest that may influence the content.

6.4. Understanding YMYL

- Definition: YMYL refers to topics that can significantly impact a person’s health, financial stability, safety, or overall well-being.

- Examples: Automotive diagnostics fall under YMYL because they involve safety-critical systems that can affect the well-being of vehicle occupants.

6.5. Why YMYL Matters in Automotive Diagnostics

- High Stakes: Incorrect or misleading diagnostic information can lead to unsafe repairs, accidents, and injuries.

- Trust and Credibility: Users must trust that the diagnostic information they rely on is accurate and reliable to make informed decisions about their vehicle’s safety.

6.6. Adhering to YMYL Principles in Content Creation

- Prioritize Accuracy: Ensure that all diagnostic information is accurate, up-to-date, and based on reliable sources.

- Emphasize Safety: Highlight the importance of safety when working on automotive systems and provide clear warnings about potential hazards.

- Seek Expert Review: Have diagnostic content reviewed by qualified automotive technicians or engineers to ensure accuracy and completeness.

- Provide Disclaimers: Include disclaimers that advise users to consult a professional mechanic or specialist for complex diagnostic and repair tasks.

- Update Regularly: Keep diagnostic content updated with the latest information and best practices to reflect changes in automotive technology and repair procedures.

6.7. Practical Steps to Enhance E-E-A-T and YMYL

- Author Credentials: Clearly display the author’s credentials, qualifications, and experience in automotive diagnostics.

- Expert Review: Have content reviewed by qualified automotive technicians or engineers.

- Citations and References: Provide citations and references to reputable sources, such as Mercedes-Benz service manuals and industry publications.

- User Reviews and Testimonials: Incorporate user reviews and testimonials to build trust and demonstrate real-world experience.

- Contact Information: Provide clear and accessible contact information for users to ask questions or report concerns.

- Privacy and Security: Ensure the privacy and security of user data by implementing appropriate measures to protect personal information.

6.8. Benefits of Adhering to E-E-A-T and YMYL

- Increased Trust: Builds trust and credibility with users, leading to greater reliance on diagnostic information.

- Improved Safety: Ensures that diagnostic information is accurate and safe, reducing the risk of accidents and injuries.

- Enhanced Reputation: Enhances the reputation of the content creator or organization as a reliable source of automotive diagnostic information.

- Better Search Engine Rankings: Improves search engine rankings by demonstrating expertise, authoritativeness, and trustworthiness to search engines like Google.

6.9. CARDIAGTECH.NET and E-E-A-T

- Expertise: CARDIAGTECH.NET provides high-quality diagnostic tools and equipment, backed by expert knowledge and support.

- Authoritativeness: As a trusted provider of automotive diagnostic solutions, CARDIAGTECH.NET is recognized as an authoritative source of information.

- Trustworthiness: CARDIAGTECH.NET is committed to providing accurate and reliable information, ensuring customer satisfaction and safety.

By adhering to the principles of E-E-A-T and YMYL, CARDIAGTECH.NET ensures that its content is accurate, reliable, and safe for users, building trust and credibility in the automotive diagnostic community. Remember, CARDIAGTECH.NET is available for all your diagnostic tool needs. Contact us at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 07050, United States, for expert assistance.

7. Real-World Case Studies: Resolving Code 9203

Examining real-world case studies can provide valuable insights into diagnosing and resolving Mercedes-Benz code 9203. These examples highlight the importance of systematic troubleshooting and the use of appropriate diagnostic tools.

7.1. Case Study 1: Faulty ETR Squib

- Vehicle: 2015 Mercedes-Benz C300

- Problem: The SRS warning light was illuminated, and a scan revealed code 9203 (Resistance value in the ignition circuit containing component R12/7 (Right rear ETR ignition squib) is too high).

- Diagnostic Steps:

- Initial Scan: Confirmed the presence of code 9203.

- Visual Inspection: Checked the wiring and connectors associated with the right rear ETR but found no obvious damage.

- Resistance Test: Disconnected the ETR connector and measured the resistance of the squib using a multimeter. The reading was infinite, indicating an open circuit.

- **